A kind of watch hairspring coiling machine

A technology for a coiling machine and a hairspring, applied in the field of coiling machines, can solve the problems of cumbersome operation procedures, low production efficiency, time-consuming and laborious, etc., and achieve the effect of eliminating operation steps, improving production efficiency, and improving rotation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The coil wire machine of the present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment:

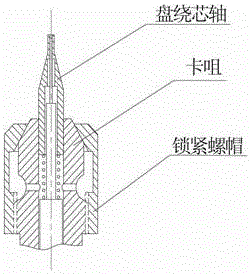

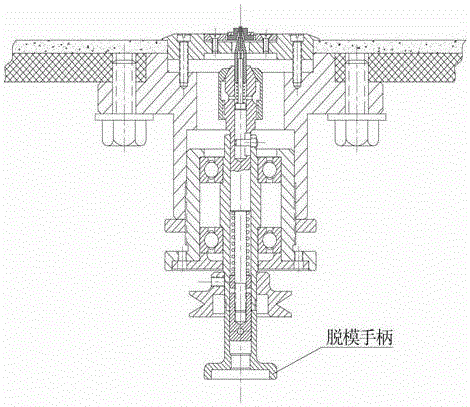

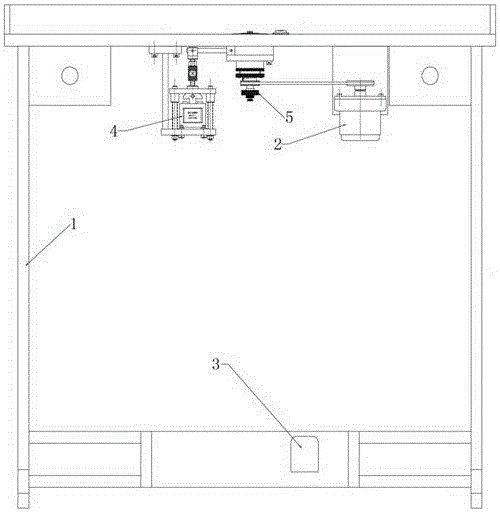

[0024] Such as Figure 3 to Figure 6 As shown, the watch hairspring winding machine of the present invention includes a driving motor 2, a driving control switch 3, an electromagnetic control assembly 4 and a coiling head 5; the driving motor 2 is hoisted and fixed on the back of the workbench of the body platform 1; The foot-operated drive control switch 3 is fixed on the pedal between the two horizontal bars at the bottom of the body platform 1, and the drive motor is controlled by the foot-operated drive control switch 3 to rotate; the electromagnetic control assembly 4 is fixed on On the fixed plate 11 at the back of the workbench of the body platform 1, the electromagnetic control assembly 4 includes an electromagnet group 41, an adjustment lock bar 42 and a linkage lever 43; one end of the adjustment lock leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com