Slicing equipment for magnetic material production

A magnetic material and slicing technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of manual feeding, incomplete cutting of NdFeB magnets, troublesome problems, etc., to change the rising height, reduce the impact, The effect of position stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

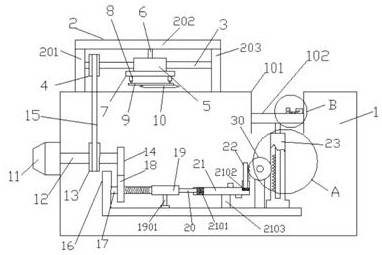

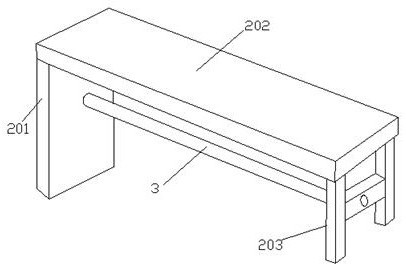

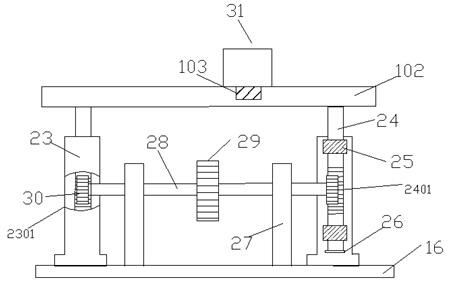

[0031] This embodiment discloses a slicing device for magnetic material production, including a box body 1, a cutting frame 2, a motor 11, a transmission system, a feeding system, and a fixing assembly 31, and a feeding trough 101 is arranged on the right side of the upper surface of the box body 1, The bottom of the feeding trough 101 is a movable base plate 102, and the movable base plate 102 is provided with a horizontal installation groove 103. The direction of the feeding chute 101 is perpendicular to the direction of the installation groove 103. The installation groove 103 is provided with a fixed assembly 31, and the fixed assembly 31 It includes extrusion block 3101, fixed seat 3102, crank arm 3103, horizontal rod 3104 and second electric push rod 3105. The fixed seat 3102 is fixedly installed on the upper surface of the installation groove 103. The joint of the curved arm 3103 is hinged with the fixed seat 3102 and its One end is movably connected with the horizontal b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com