Hydraulic expansion type chuck for workpiece clamping machining

An expansion type, workpiece clamping technology, applied in the direction of the chuck, etc., can solve the problems that the three jaws cannot clamp the workpiece, the chuck or external hazards, and the workpiece is easy to fly out of the chuck, so as to reduce wear and tear and improve safety , Improve the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

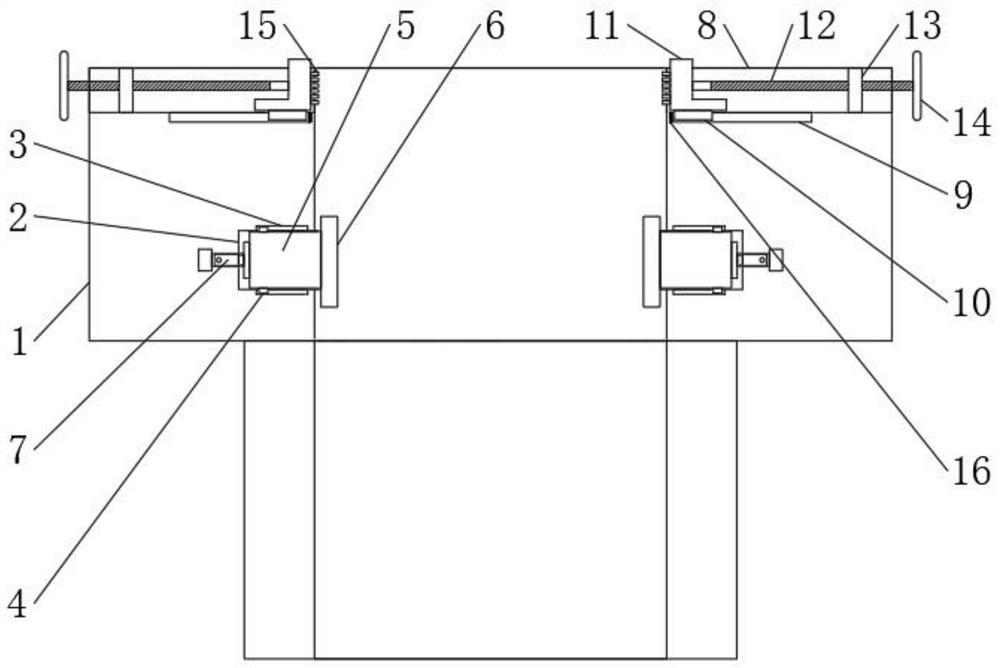

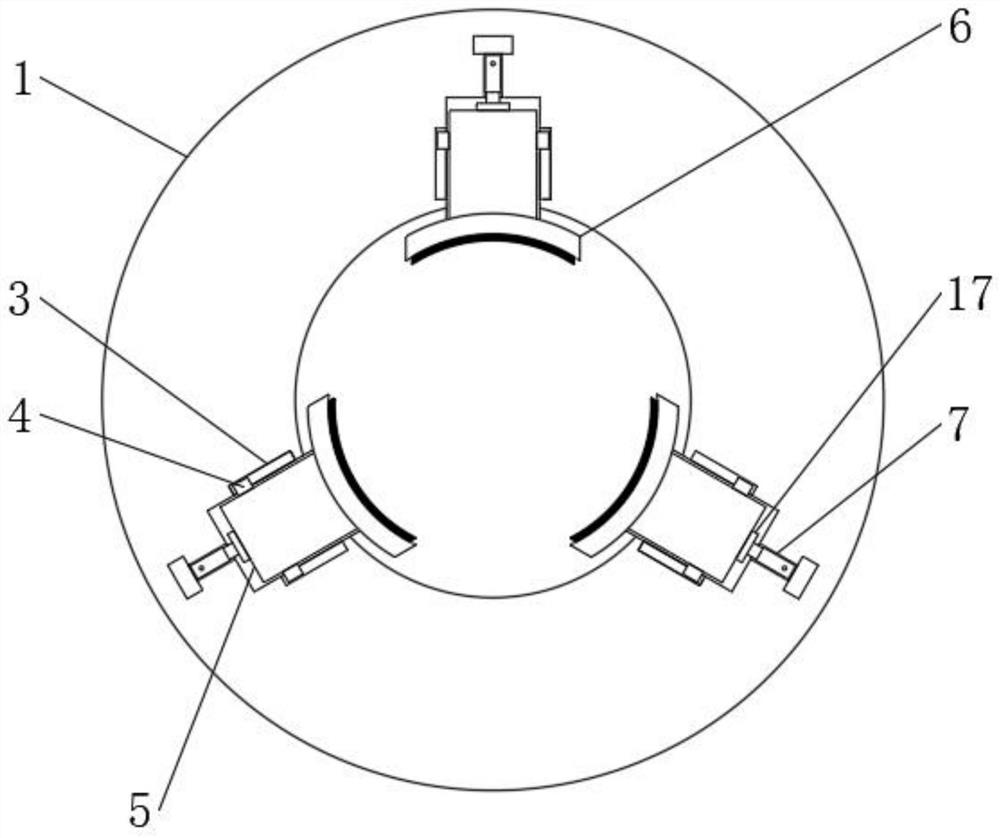

[0031] see Figure 1-2 , a hydraulic expansion chuck for workpiece clamping processing, including a chuck main body 1, a plurality of evenly distributed installation grooves 2 are dug in the inner wall of the chuck main body 1, and a pair of first slides are dug in the inner wall of the installation groove 2 Slot 3, the inside of the first chute 3 is slidably connected with a first slider 4, a pair of first sliders 4 is fixedly connected with a fixed block 5, and the outer end of the fixed block 5 is fixedly connected with an arc-shaped clamping plate 6, The bottom wall of the installation groove 2 is dug with a card groove, and a hydraulic rod 7 is installed inside the card groove. Evenly distributed working grooves 8, the working grooves 8 are located on the upper side of the installation groove 2, the inner bottom wall of the working groove 8 is dug with a second chute 9, and the inside of the second chute 9 is slidably connected with a second slide block 10. The upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com