Building construction steel bar cut-off machine with multi-angle position cutting function

A steel bar cutting machine and construction technology, which is applied in the field of steel bar cutting machine, can solve the problems such as the manual hand-held steel bar grinding angle is not smooth enough, wastes time to use manual hand-held steel bar grinding angle, and cannot meet the special requirements of the steel bar angle, etc., to achieve convenience Adjust the cutting position, save manual labor, and prevent cutting deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

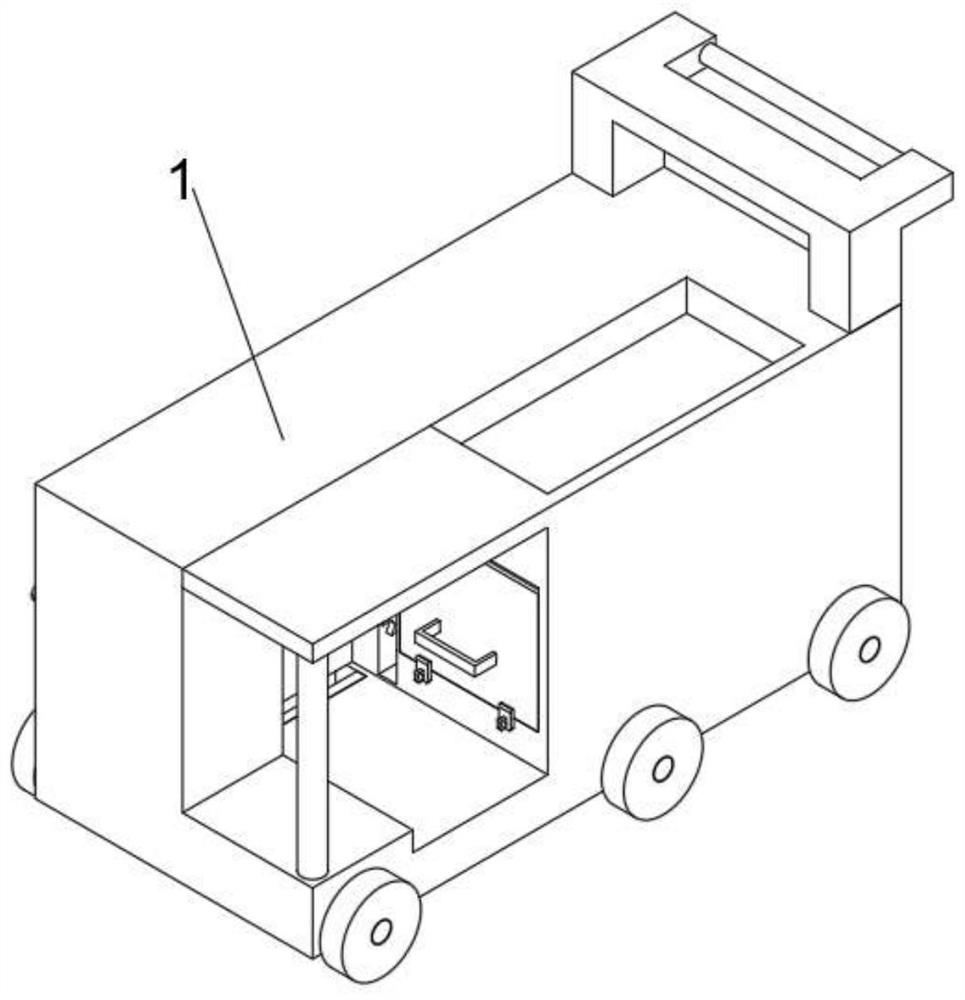

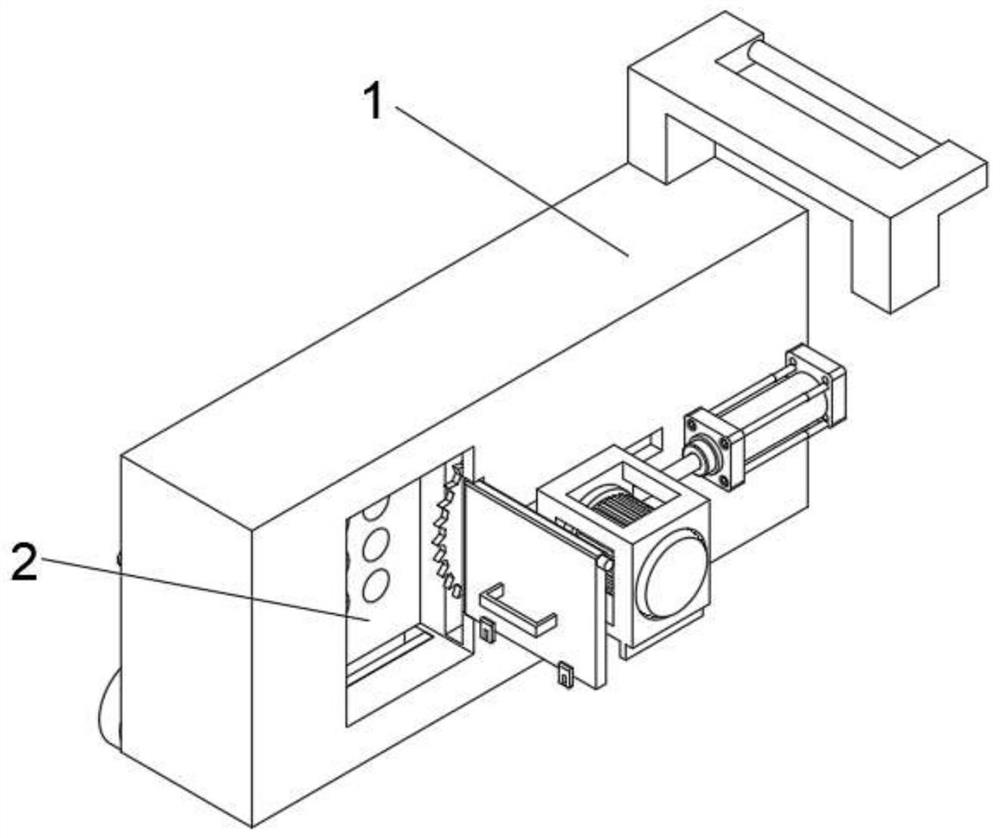

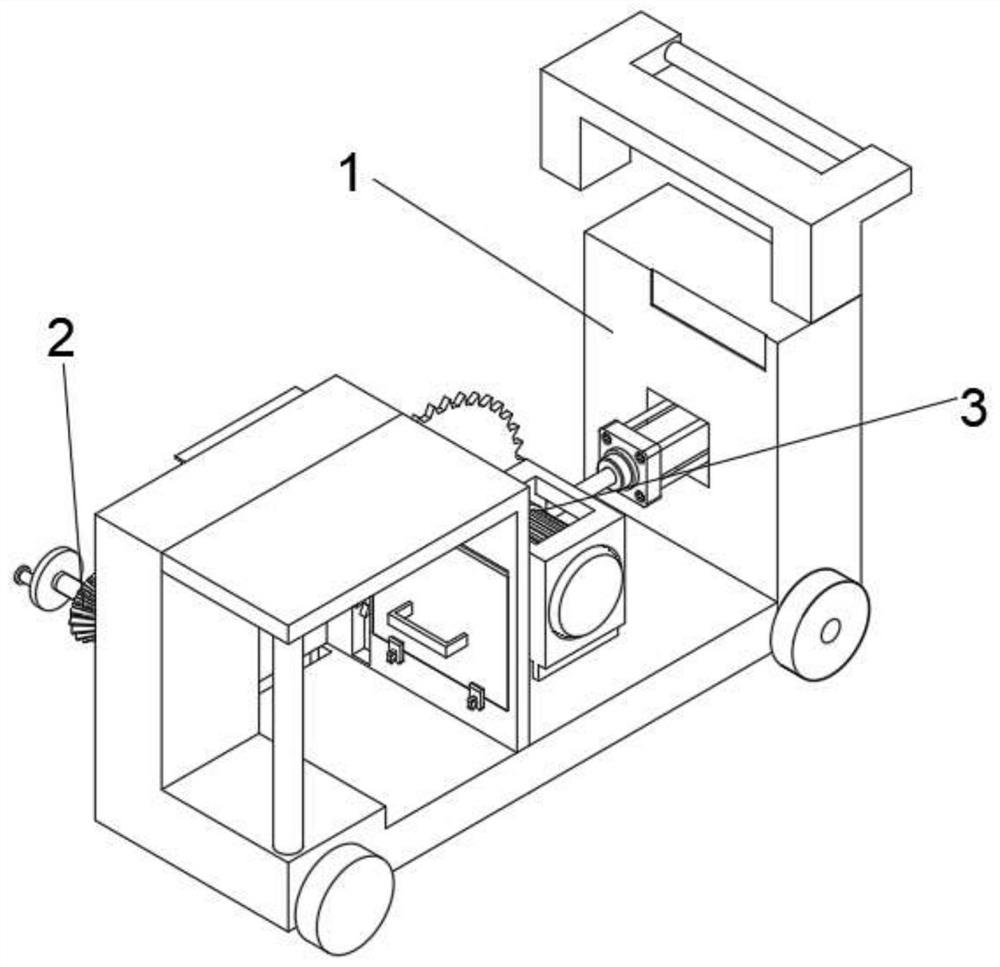

[0049] see Figure 1-Figure 10 As shown, there is provided a kind of steel bar cutting machine for building construction with multi-angle position cutting, including a moving device 1, a feed regulating device 2 is arranged inside one side of the moving device 1, and a cutting device is arranged on one side of the feeding regulating device 2 device 3;

[0050] The mobile device 1 includes a housing 11, one side of the housing 11 is provided with a discharge platform 114, and the top and bottom of one side of the discharge platform 114 are symmetrically provided with a semicircular movable groove 116, and both sides of the movable groove 116 are provided with one end. There is a limit baffle 1161 that snaps into the baffle, and a number of moving rollers 14 are symmetrically arranged on both sides of the bottom of the casing 11;

[0051] When the mobile device 1 of this embodiment is in use, hold the grip bar 122 with both hands to push the casing 11, and a plurality of moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com