Adhesive dispensing machine for non-woven fabric

A technology of glue machine and dispensing gun, which is applied to the device and coating of the surface coating liquid, which can solve the problems of sticking, glue stains, and glue prone to stringing, etc., so as to avoid damage and pull lifting and indentation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

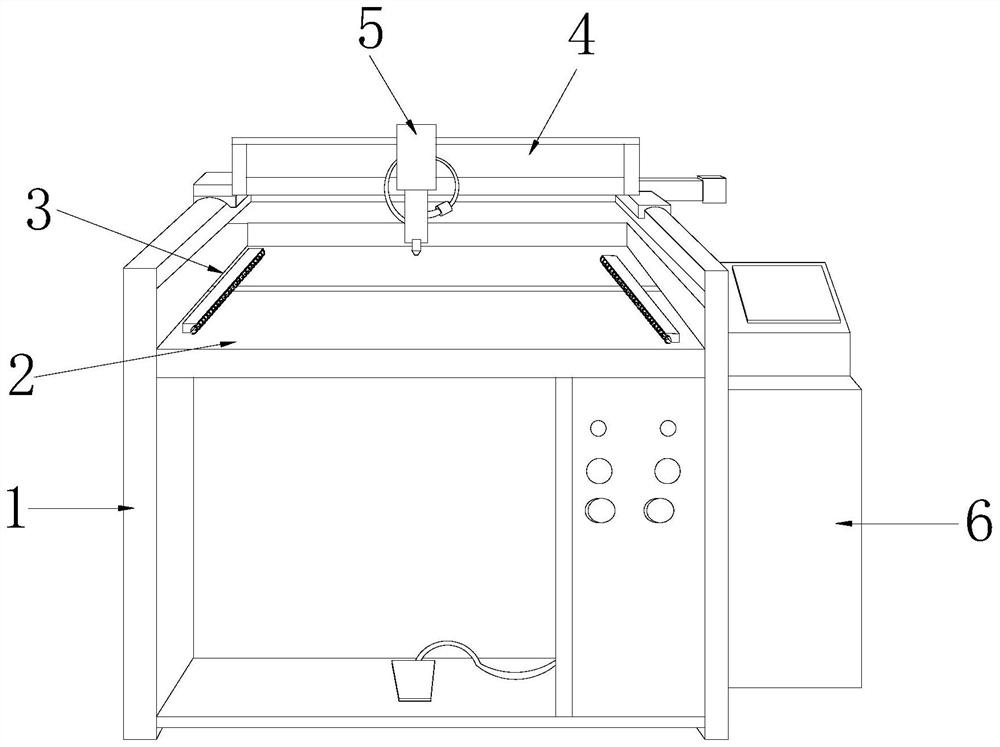

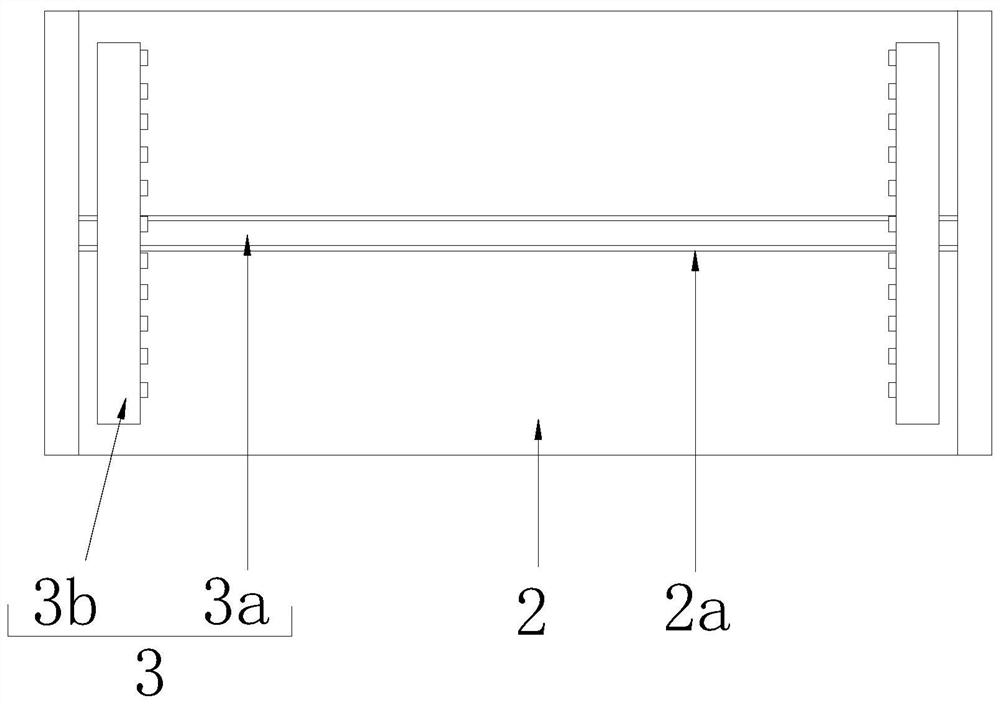

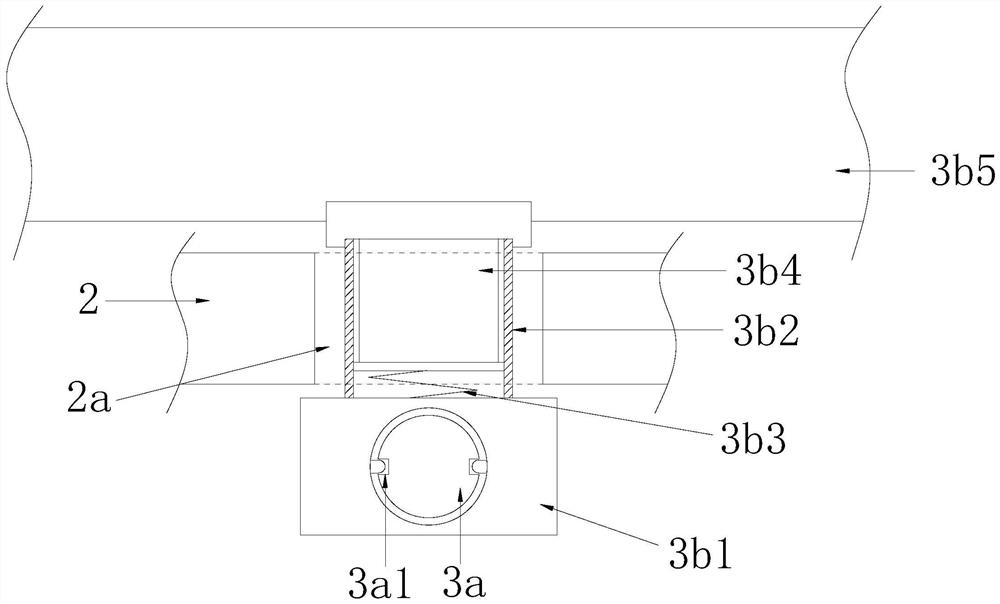

[0030] Such as Figure 1-Figure 7 As shown, the invention provides a kind of technical scheme of non-woven glue dispensing machine:

[0031] Such as Figure 1-Figure 3 As shown, a non-woven fabric dispensing machine, its structure includes equipment main body 1, workbench 2, anti-movement device 3, moving frame 4, dispensing gun 5, controller 6, and the workbench 2 is installed on the equipment The upper surface of the main body 1, the anti-movement device 3 is arranged on the upper surface of the workbench 2, the moving frame 4 is installed on the upper surface of the equipment main body 1 and cooperates, the dispensing gun 5 is connected with the moving frame 4, and the The controller 6 is installed on the right side of the equipment main body 1 and electrically connected. The anti-movement device 3 includes a guide rod 3a and a pressure regulating mechanism 3b. The guide rod 3a is installed under the workbench 2 and is transverse to the equipment main body 1. In connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com