Acetylene efficient separation material

A technology for separation materials and adsorption separation materials, applied in the field of high-efficiency separation materials for acetylene, can solve the problems of aggravating ethane/ethylene separation tasks, waste of ethylene products, small product synthesis amount, etc. The effect of growth, fast and accurate performance judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

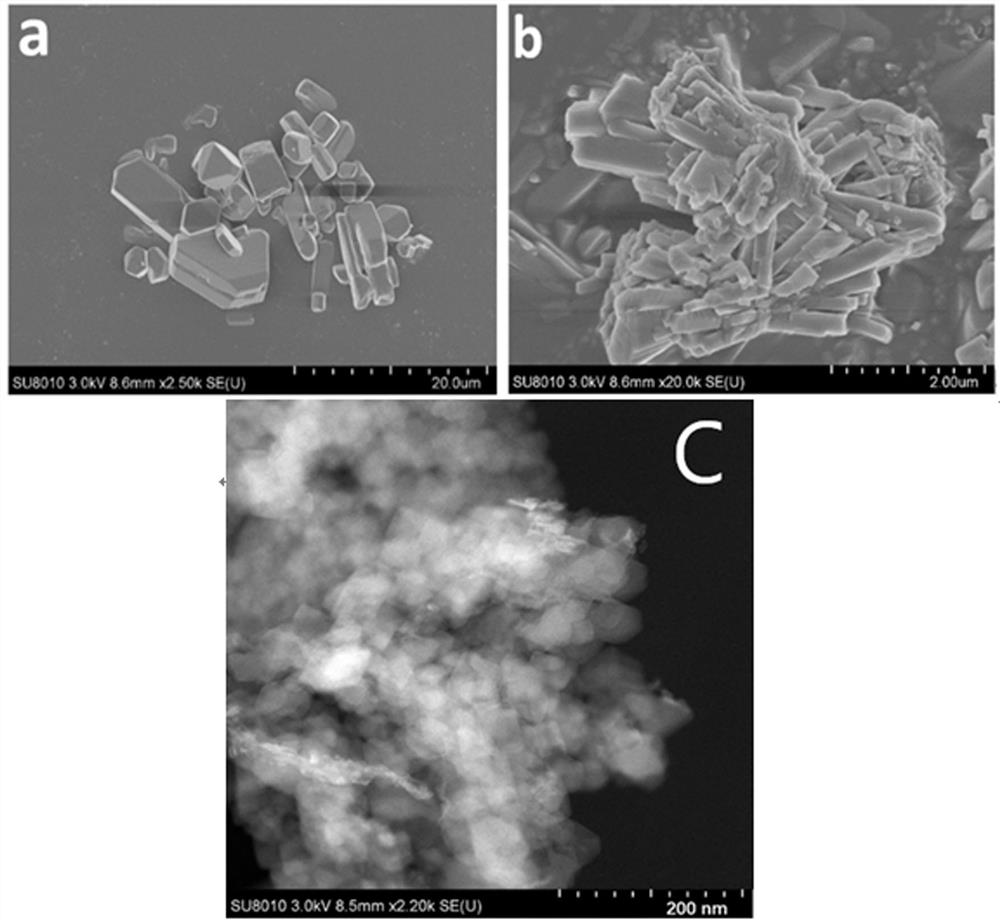

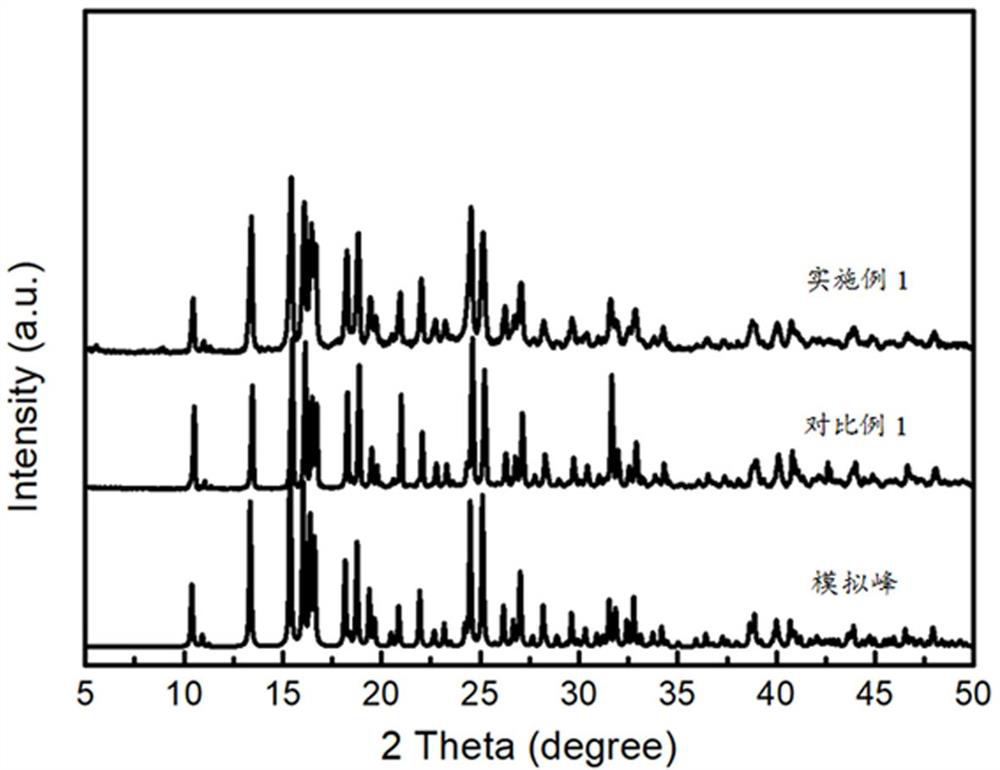

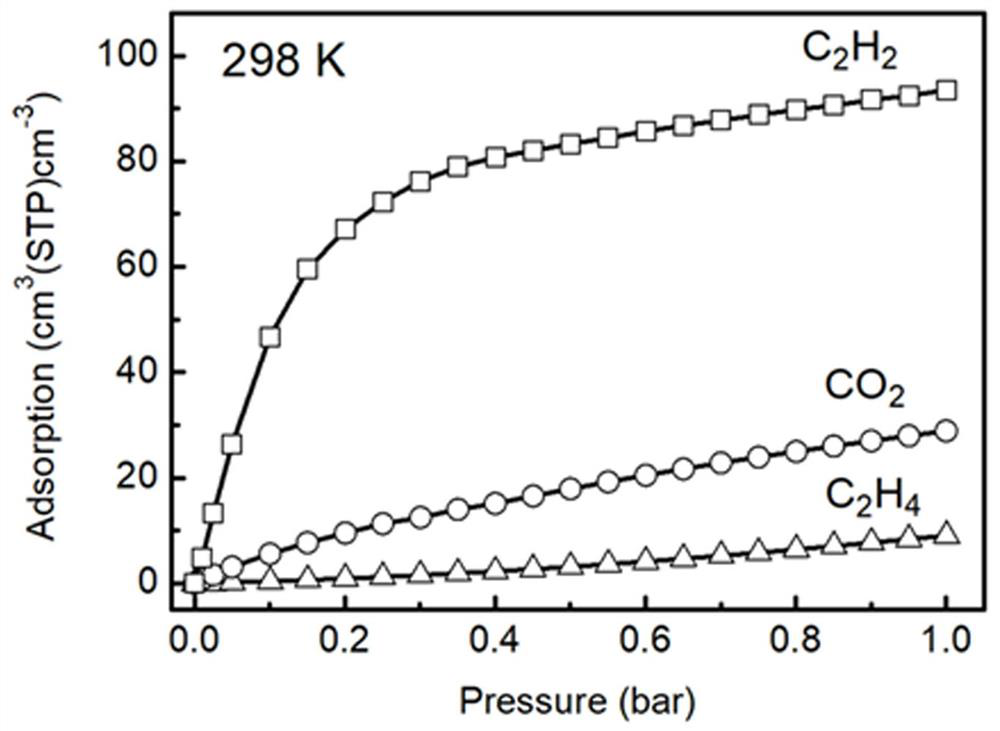

[0045] A high-efficiency separation material for acetylene, the separation material contains chemical formula [Zn 2 (bpy)(btec)(H 2 O) 2 ]·2H 2 The metal organic framework material of O, the preparation method of described separation material comprises the following steps:

[0046] Step 1: Add zinc source, pyromellitic dianhydride and 4,4'-bipyridine into deionized water, and stir;

[0047] Step 2: Stir and mix evenly, add ammonia water or ammonium salt, and continue to stir for a period of time;

[0048] Step 3: After the reaction is completed, the obtained precipitate is filtered, washed and dried to obtain an isolated material.

[0049] Ammonia or ammonium salt is added during the synthesis process, which can form pyromellitic acid ammonium salt with pyromellitic dianhydride, accelerate the combination of pyromellitic acid ammonium salt with Zn ions in aqueous solution, and promote [Zn 2 (bpy)(btec)(H 2 O) 2 ]· 2 h 2 O grows rapidly and can increase [Zn 2 (bpy)(bt...

Embodiment 1

[0066] Add 0.150 kg of zinc acetate, 0.0764 kg of pyromellitic dianhydride and 0.0547 kg of 4,4'-bipyridine to 1.0 L of deionized water, stir and mix evenly, then add 2 mL of ammonia water with a mass concentration of 25%, And control the temperature at 25°C, keep stirring for 2 h, filter, wash with water / ethanol (1:1) mixed solution, and dry the obtained filter cake to obtain the product.

Embodiment 2

[0068] Add 0.150 kg of zinc acetate, 0.0764 kg of pyromellitic dianhydride and 0.0547 kg of 4,4'-bipyridine to 1.0 L of deionized water, stir and mix evenly, then add 2 mL of ammonia water with a mass concentration of 25%, And control the temperature at 50°C, keep stirring for 0.5 h, filter, wash with water / ethanol (1:1) mixed solution, and dry the obtained filter cake to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com