Ultra-high molecular weight polyethylene fiber sock production system and static electricity removing method thereof

A polyethylene fiber and ultra-high polymer technology, applied in socks, pantyhose, textiles and papermaking, etc., can solve problems such as yarn contact with the ground, affecting production efficiency, and knotting, so as to avoid knotting and ensure The effect of ensuring production quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

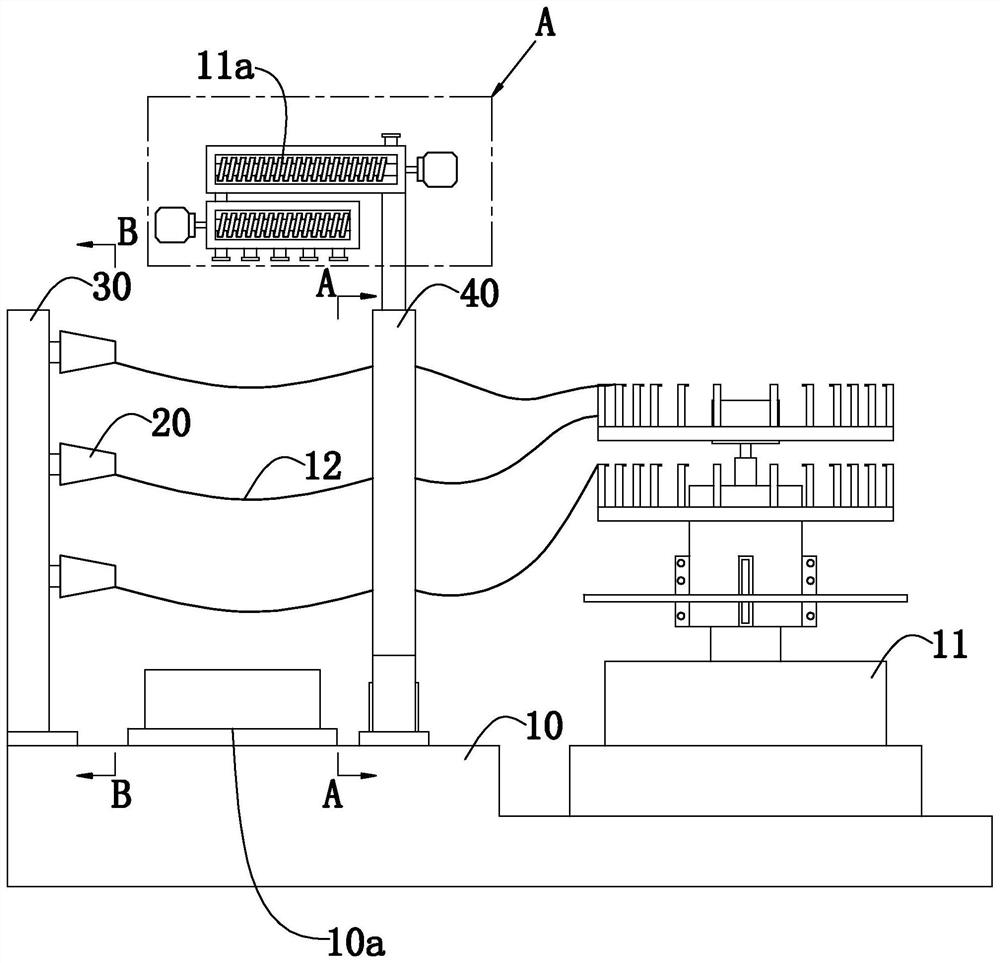

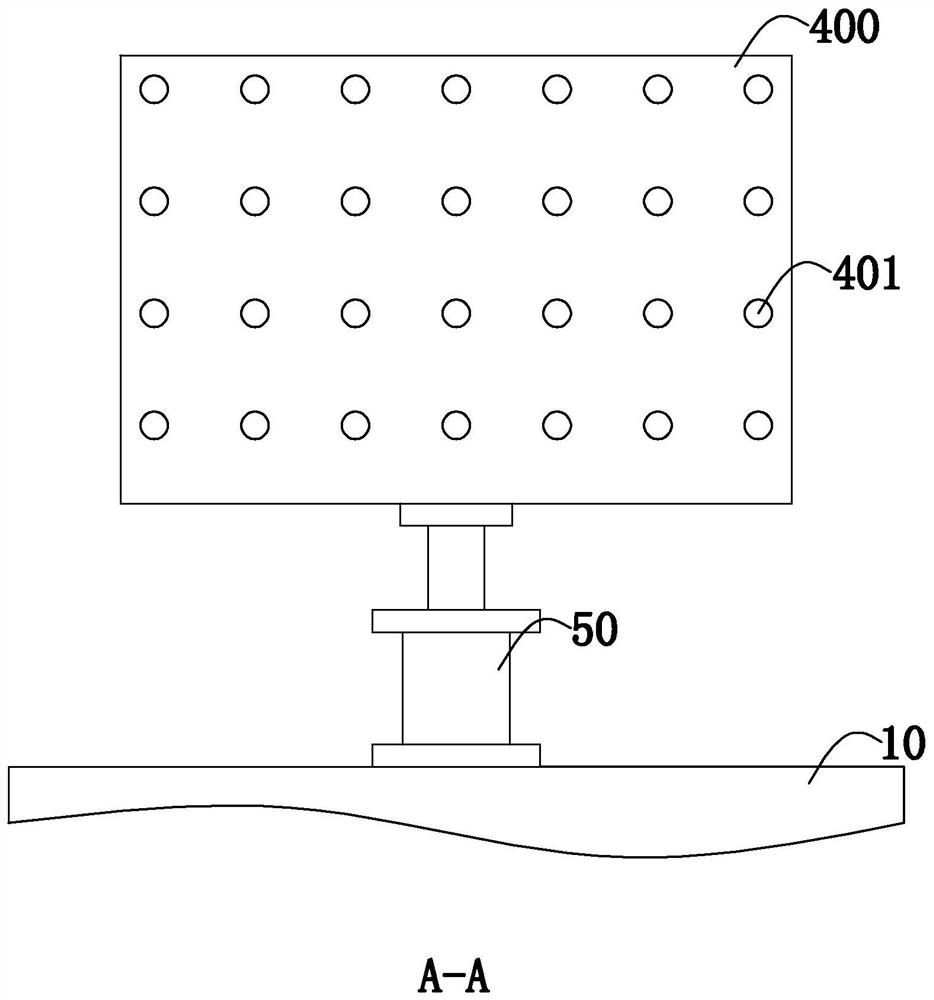

[0053] Such as Figure 1-Figure 6 As shown, the present invention discloses a production system of ultra-high molecular polyethylene fiber socks, including a frame 10 and a knitting module 11 installed on the frame 10, in a specific embodiment of the present invention, including a The yarn supply module 30 installed on the frame 10 and the yarn supply cylinder 20, the thread management module 40 installed between the yarn supply module 30 and the knitting module 11, and the yarn supply module 40 installed on the yarn supply module 30 and the wire management module 40 and / or the powder sprinkler module 11a between the wire management module 40 and the knitting module 11 and the dust suction module installed on the frame 10 and corresponding to the powder sprinkler module 11a 10a; wherein, the wire management module 40 includes a board 400 installed on the frame 10 and located between the yarn supply module 30 and the knitting module 11, and several boards arranged on the board ...

Embodiment 2

[0070] Embodiment 2, the difference with embodiment 1 is that

[0071] Such as Figure 7-Figure 10As shown, in the specific embodiment of the present invention, it also includes an adjustment module 50 installed on the frame 10 and used to control the lifting of the board body 400 and to straighten the yarn 12; wherein, the adjustment module 50 includes The support rod 500 is installed on the frame 10 and has a main frame body 502 with a hinged area 501, at least two first support body 504 and a second support body that are rotatably connected to the inner side wall of the hinged area 501 through a rotating shaft 503 505, the hinge module 506 connected between any end of the first support body 504 and the second support body 505 and the board body 400, hinged on the main frame body 502 and used to drive the second support body 502 A support body 504 rotates with the rotating shaft 503 as the base point and lifts the first cylinder 507 of the plate body 400 through the hinge m...

Embodiment 3

[0084] Embodiment 3, the difference with embodiment 2 is that

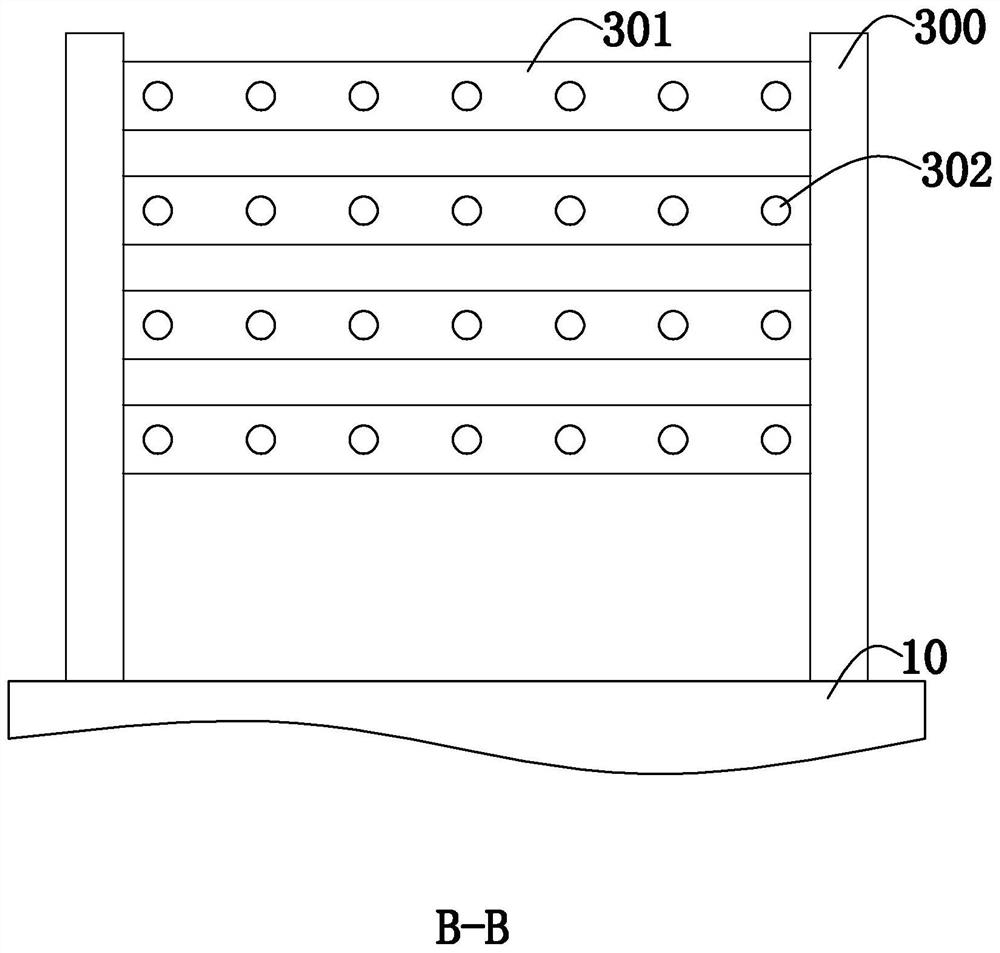

[0085] Such as Figure 11-Figure 16 As shown, in the specific embodiment of the present invention, the wire holes 401 on the board body 400 have several rows arranged at intervals in the longitudinal direction; The fine adjustment module 60 corresponding to and capable of straightening the yarn 12; wherein, the fine adjustment module 60 includes a rod seat 600 which is in contact with the board body 400 and is located above or below each wire hole 401 and is hollowly arranged. The sliding groove 601 on the top end surface or the bottom end surface of the rod base 600 and communicated with the inside of the rod base 600, the drive shaft 603 arranged inside the rod base 600 and driven by the plc motor 602, at least one is provided on the rod base 600 The limit rib 604 on the drive shaft 603 and extending along the drive shaft 603, several transmission chambers 6050 fitted on the drive shaft 603 and adapted to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com