Brake pad stamping die with good heat dissipation performance

A technology for stamping dies and brake pads, used in forming tools, manufacturing tools, vehicle parts, etc., which can solve problems such as reducing the durability of parts, accelerating machine aging, and failing to meet processing needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

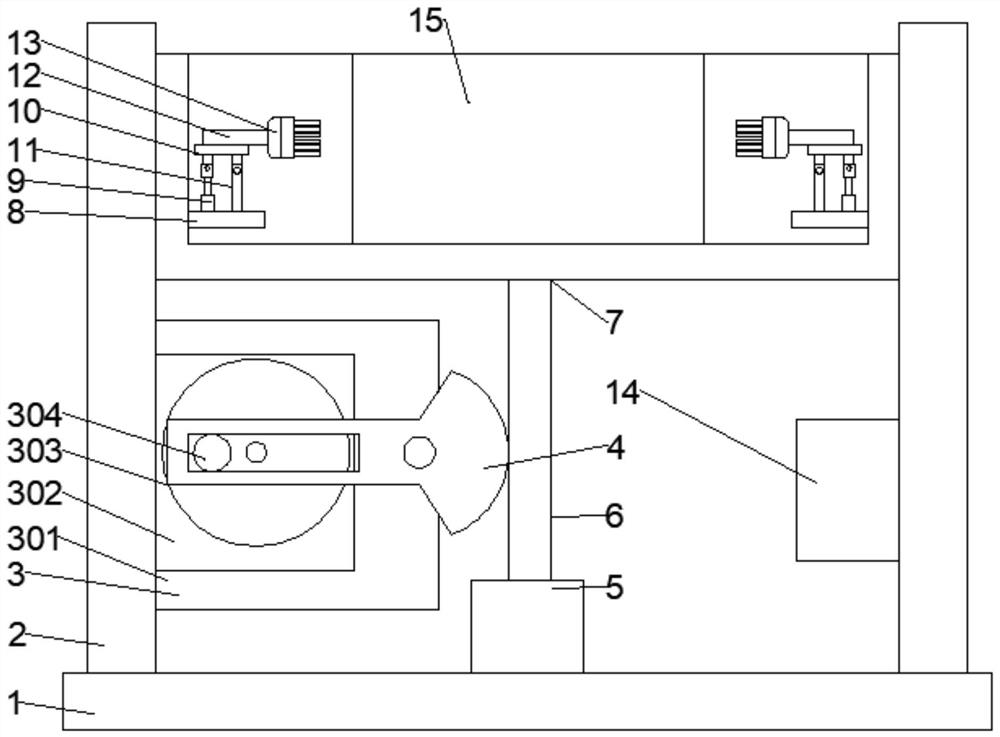

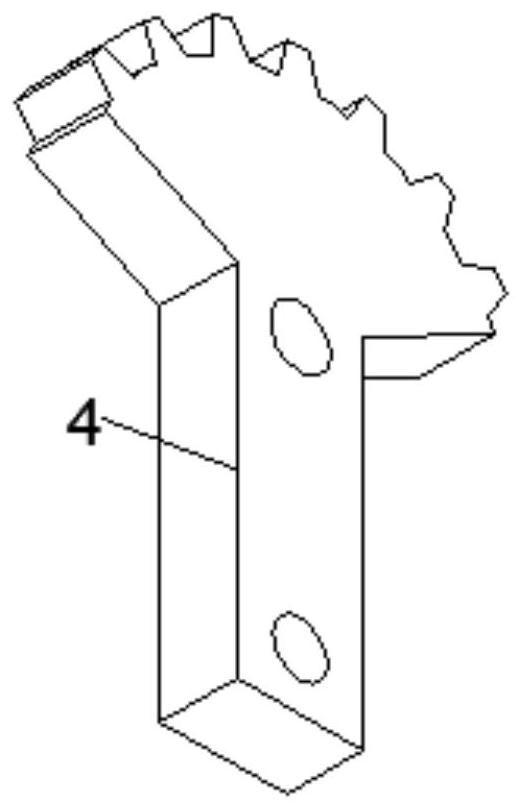

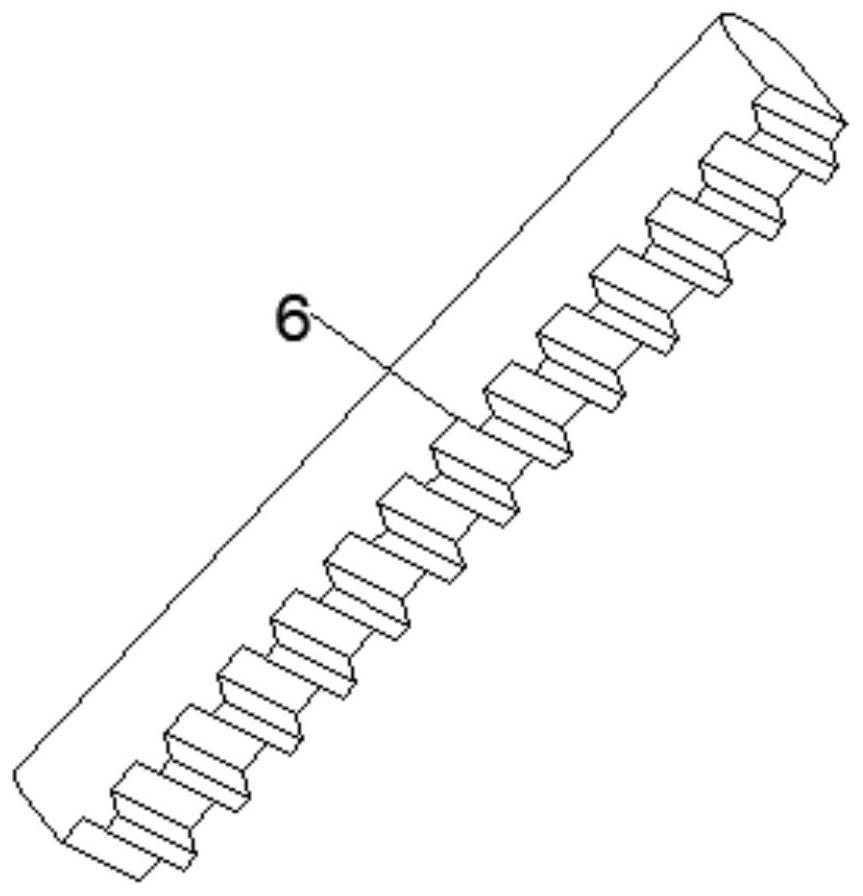

[0021] Example 1: Please refer to Figure 1~3 , in an embodiment of the present invention, a brake pad stamping die with good heat dissipation includes a bottom plate 1 and a support column 2, the support column 2 is fixedly connected to the top of both sides of the bottom plate 1, and the drive mechanism 3 is fixedly connected to the bottom of the left support column 2 , the drive mechanism 3 is rotatably connected with a sector gear handle 4 with a closed square chute at the left end, a fixed block 5 is fixedly connected above the middle part of the bottom plate 1, and the middle part of the fixed block 5 is slidably connected with a left side meshing with the right end of the sector gear handle 4 The sliding rack 6, the upper end of the sliding rack 6 is fixedly connected with the mounting frame 7 slidingly connected with the supporting column 2, the fixing plate 8 is fixedly connected under the two sides of the mounting frame 7, and the electric push rod 9 is fixedly connec...

Embodiment 2

[0026] Embodiment 2: This embodiment is a further improvement of the previous embodiment: the lower end of the right support column 2 is fixedly connected with a controller 14, which is convenient for controlling the operation of the motor 302 and the electric push rod 9 .

[0027] The working principle of the present invention is: the motor 302 drives the turntable 303 to rotate, and then drives the sliding column 304 to rotate, and then drives the sector gear handle 4 to swing up and down through the sliding of the sliding column 304 in the closed square chute, and then drives the sliding teeth through the meshing of the teeth The bar 6 slides up and down, and then realizes the adjustment of the height position of the mounting frame 7; the electric push rod 9 drives the swing plate 10 to swing, and then drives the connecting shaft 12 to swing, and then drives the refrigerator 13 to swing, thereby fully cooling and dissipating heat inside the mounting frame 7, Effectively avoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com