Intelligent screening equipment for clothing buttons

A technology for screening equipment and buttons, applied in the field of intelligent screening equipment for clothing buttons, can solve the problems of reducing factory production efficiency, slow screening efficiency, and inconvenient button screening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

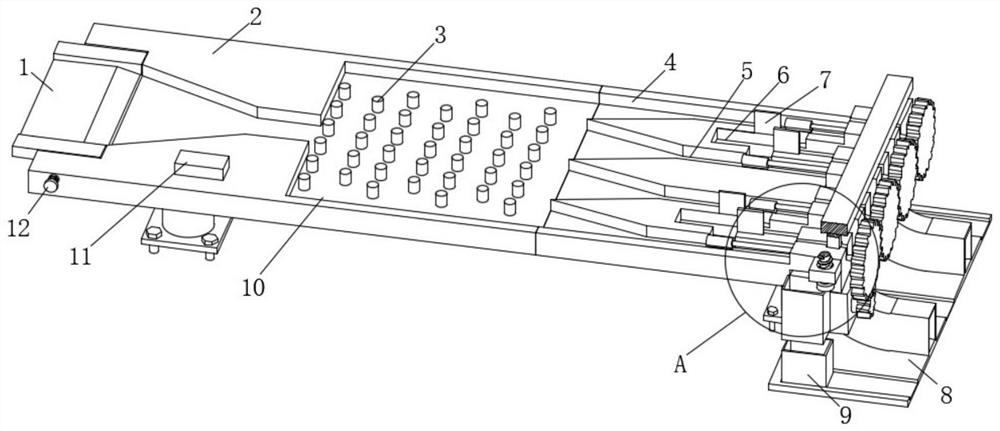

[0029] Embodiment 1: Clothing button intelligent screening equipment, including left housing 2, angle adjustment unit 21 and screening unit 15;

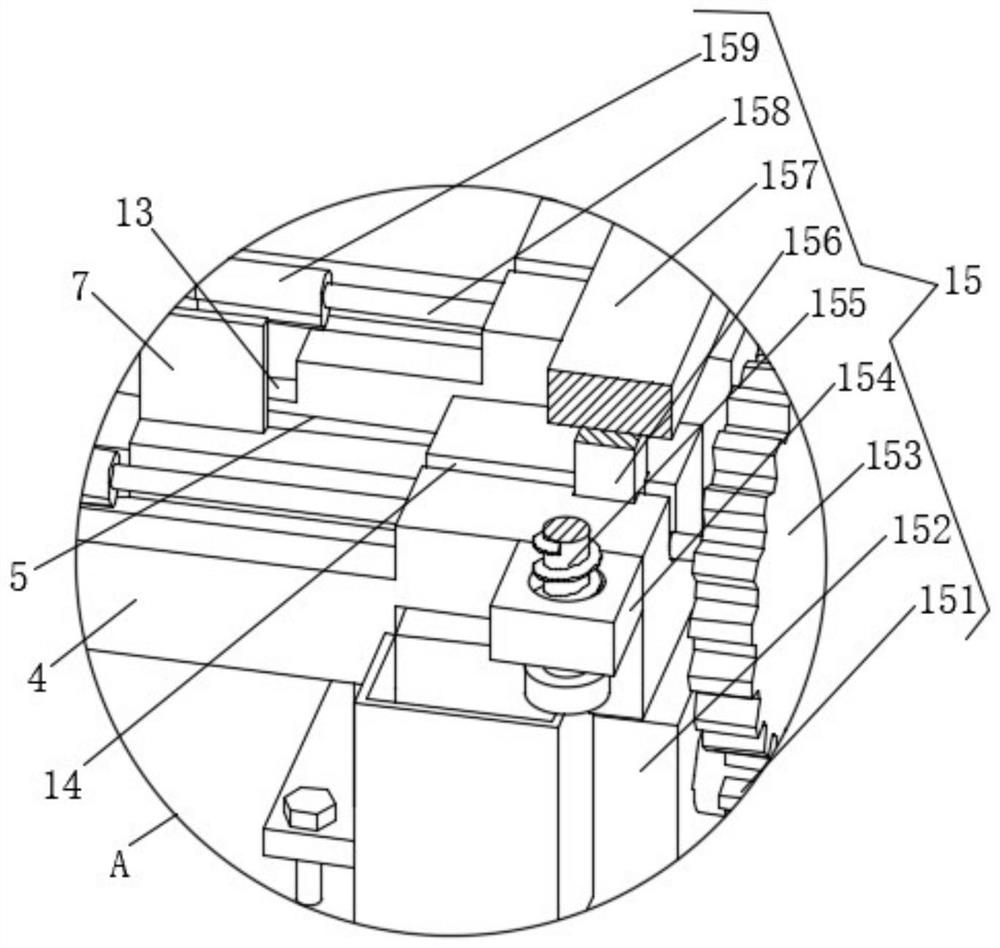

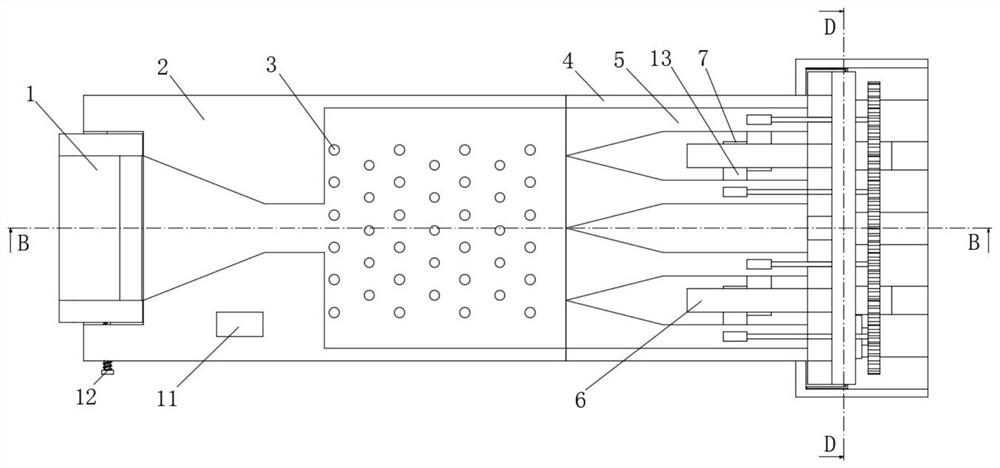

[0030] Left housing 2: the upper side of the right end is provided with an equalizing groove 10, and the left side of the equalizing groove 10 is provided with a buckle groove, the right end of the left housing 2 is fixed with a right housing 4, and the upper side of the right housing 4 is in a linear array A total flow channel 5 is arranged, and the total flow channel 5 is arranged correspondingly to the left and right sides of the equalizing channel 10. The right end of the total flow channel 5 is provided with a thin buckle exit hole 17, and the opening directions of the front and rear two thin buckle exit holes 17 are opposite. The upper side of the body 4 is arranged in a linear array with thick buckle outflow grooves 6. The thick buckle outflow grooves 6 are located between the right ends of the front and rear two main flow groo...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is:

[0036] In this embodiment, it also includes an external extension plate 1, which is movably interspersed at the left end of the left housing 2, and its right end is arranged correspondingly to the left and right sides of the button entry groove, and the external button output device can be connected through the external extension plate 1, so that the button can be directly released from the button. The previous production equipment flows into this device, and also includes an angle adjustment hole 16, which is arranged on the left end of the left housing 2, which is located directly below the right end of the external extension plate 1, because the left housing 2 and the right housing 4 need to rotate Therefore, it is necessary to rotate the external extension plate 1 to make the device cooperate with the last button production and output device in real time, and the angle adjustment hole 16 prevents the exter...

Embodiment 3

[0038] The difference between this embodiment and embodiment two is:

[0039] In this embodiment, it also includes a sub-button column 3, which is arranged in a rectangular array on the lower side of the equalizing groove 10. The buttons can be evenly divided into each main flow channel 5 through the sub-button column 3, and a thick button is also included. Outgoing pipe 18 and thin buckle outlet pipe 19, the linear array of thick button outlet pipe 18 is arranged on the lower right end of the right housing 4, the thick button outlet pipe 18 is set up and down correspondingly with the thick button outflow groove 6, and the thin button outlet pipe 19 The linear array is arranged at the right end of the lower side of the right housing 4, and the thin buckle outlet pipe 19 and the thin button outlet hole 17 are arranged correspondingly up and down, and the button can be directional conveyed through the thick button outlet pipe 18 and the thin button outlet pipe 19, so that the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com