Automatic alcohol spraying device

A technology of automatic spraying and spraying device, applied in the direction of spraying device, etc., can solve the problems of high labor intensity, hidden danger of personal equipment safety, large economic loss, etc., and achieve simple and reliable structural design, low labor intensity of workers, and anti-oxidation. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

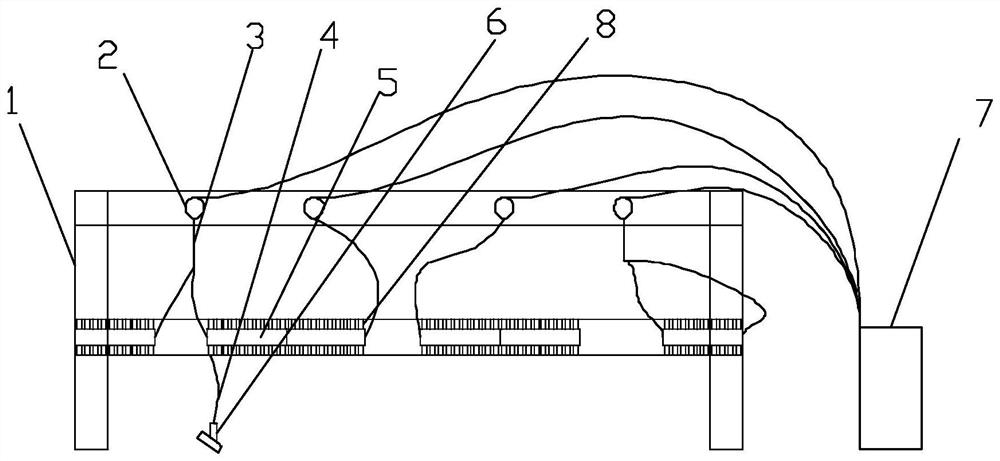

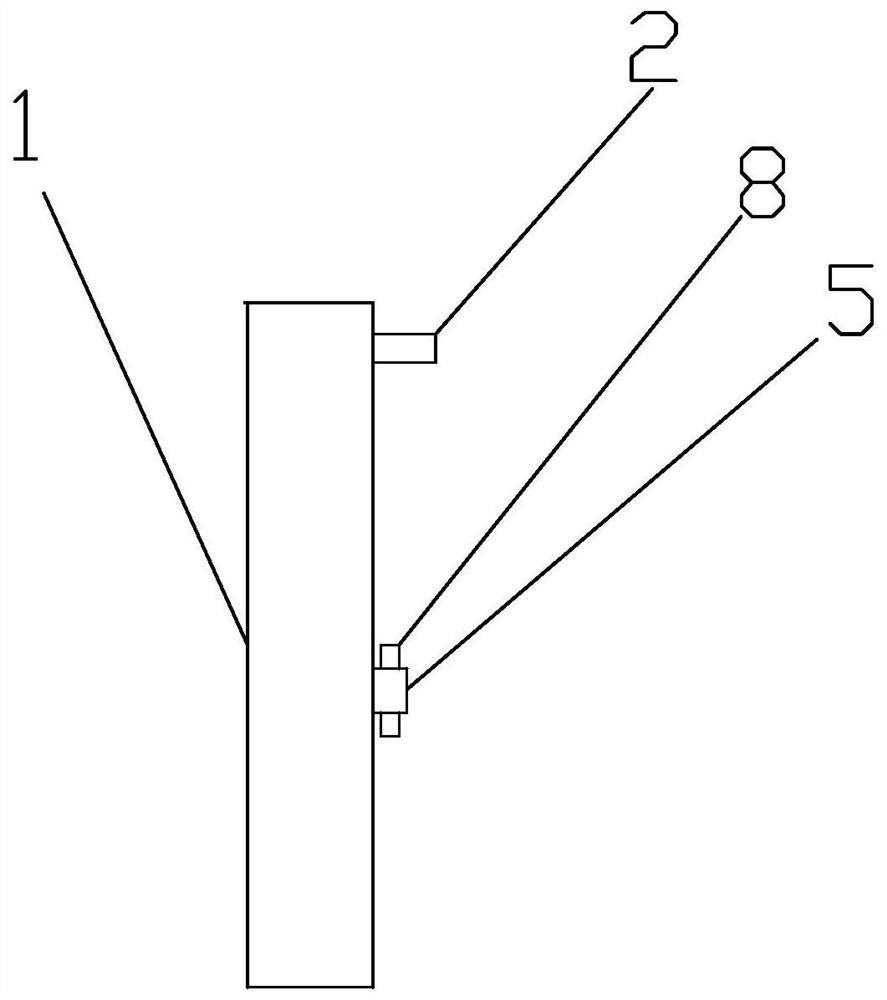

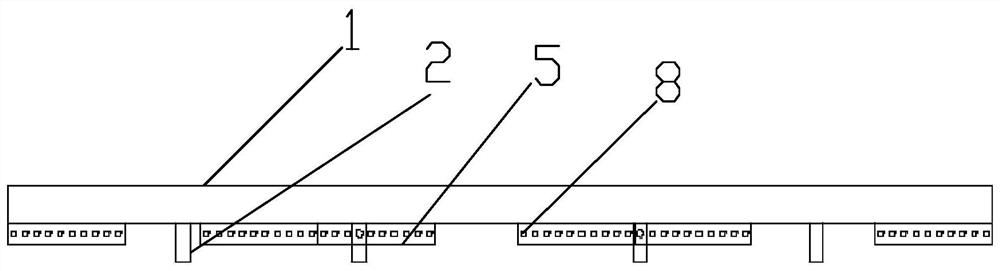

[0023] Such as Figure 1-3 As shown, one embodiment of the present invention discloses an automatic alcohol spraying device, including an alcohol spraying device, a disconnection detection device, and a disconnection sound and light alarm;

[0024] The alcohol spray device includes a double-row steel bracket 1 and an adjustable alcohol gas storage tank 7. The upper beam of the double-row steel bracket 1 is evenly provided with four solenoid valves 2, and the four solenoid valves 2 are all connected to the adjustable alcohol gas storage tank 7. The lower beam of the double-row steel bracket 1 is evenly equipped with several rows of air outlets 5, the air outlets 5 are connected to the solenoid valve 2 through the first air pipe 3, and the air outlet 5 is connected to the Y-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com