Method for preparing propionic acid by catalysis of lactic acid

A technology for the preparation of catalysis and propionic acid, which is applied in the preparation of carboxylate, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of great influence on stirring efficiency, complex equipment structure, and high sealing requirements, and achieve stirring without dead ends. , Stirring structure is simple, the effect of improving the stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Lactic acid is catalyzed to prepare propionic acid method, comprises the following steps:

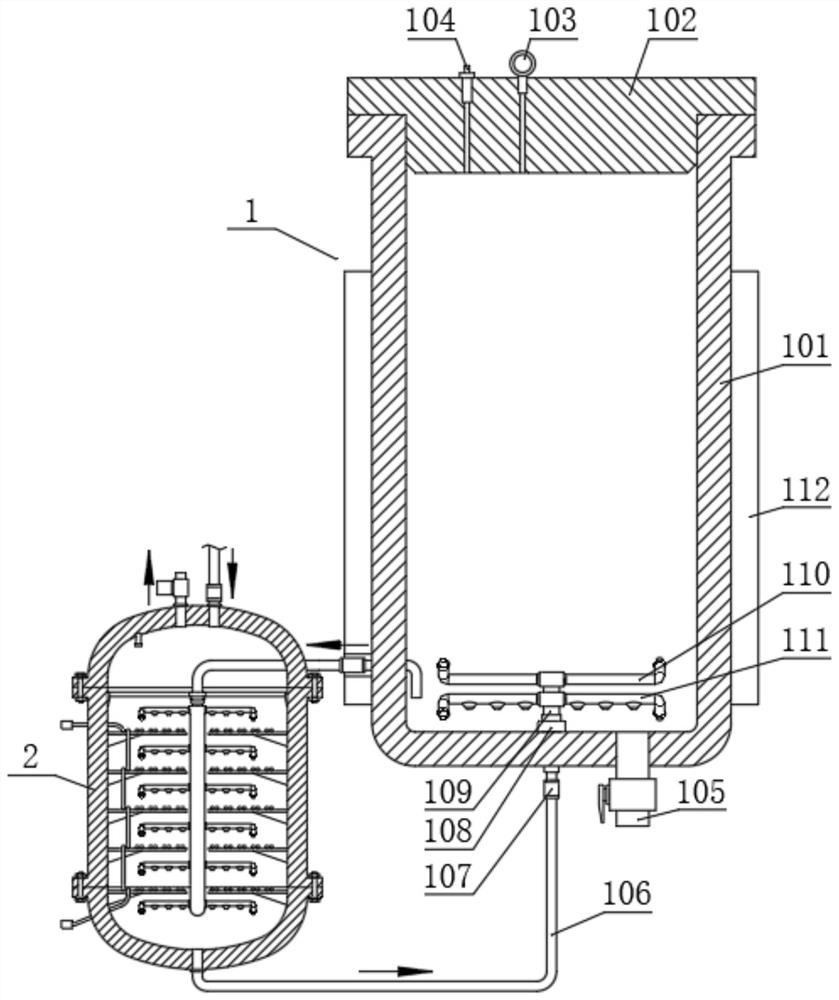

[0028] Step A: adding materials into the reaction tank 101 of the reaction component 1 of the preparation device, and closing the sealing cover 102 of the reaction tank 101;

[0029] Step B: Turn on the heating assembly 112 of the reaction assembly 1 to heat the material:

[0030] Step C: The material is reacted in the reaction tank 101:

[0031] Step D: After the reaction is completed, the sealing cover 102 is opened, and the reacted material is discharged from the discharge pipe 105 opened at the bottom of the reaction tank 101 .

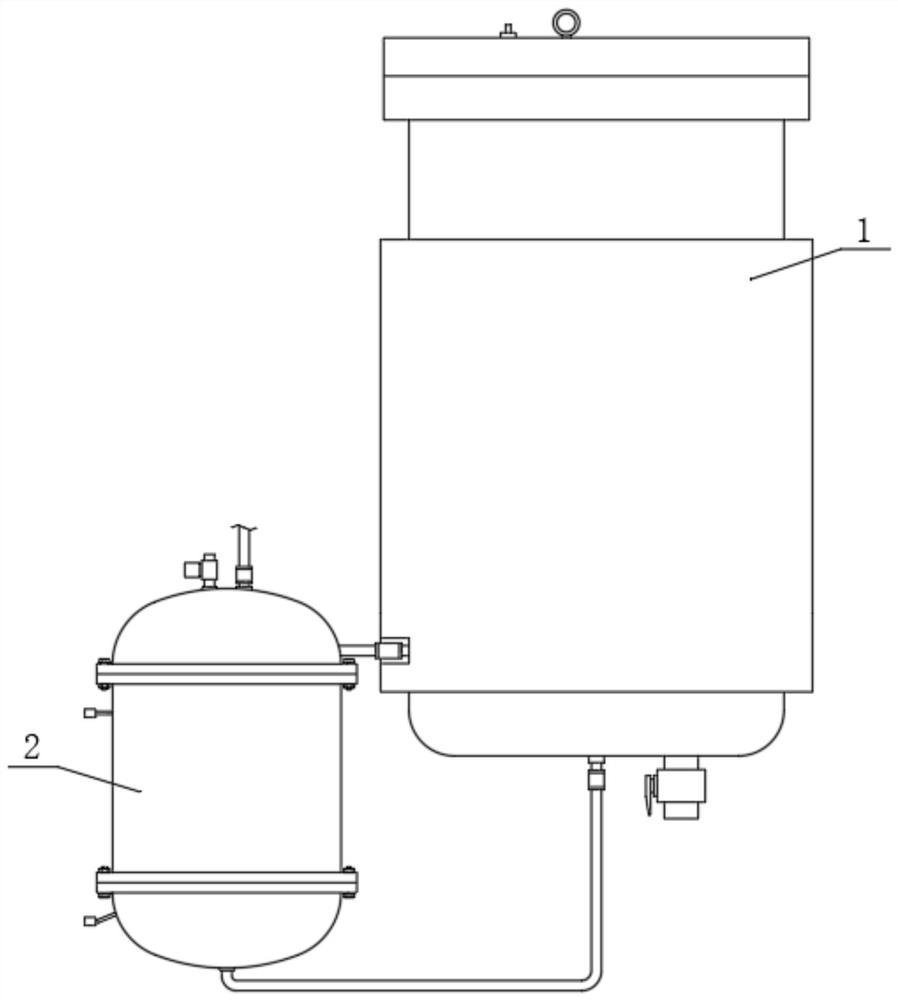

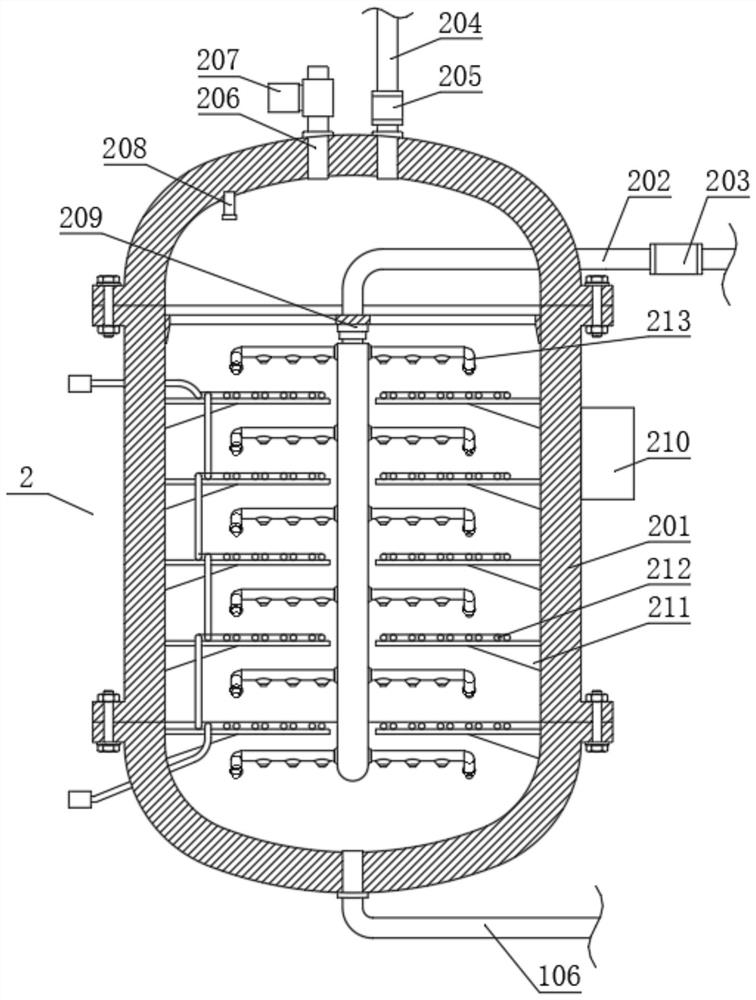

[0032]see figure 1 , the preparation device also includes a reaction assembly 1, a circulation assembly 2 and a filter assembly 3, the bottom of the reaction assembly 1 is communicated with a return pipe 106, and the reaction assembly 1 is communicated with the bottom of the circulation assembly 2 through the return pipe 106, as figure 2 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com