Hawthorn kernel separation equipment for food processing

A technology for separation equipment and food processing, which is applied in fruit pitting devices, applications, food science, etc. It can solve the problems of manual replacement of hawthorns that take a long time, holding hawthorns for a long time, and cumbersome problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

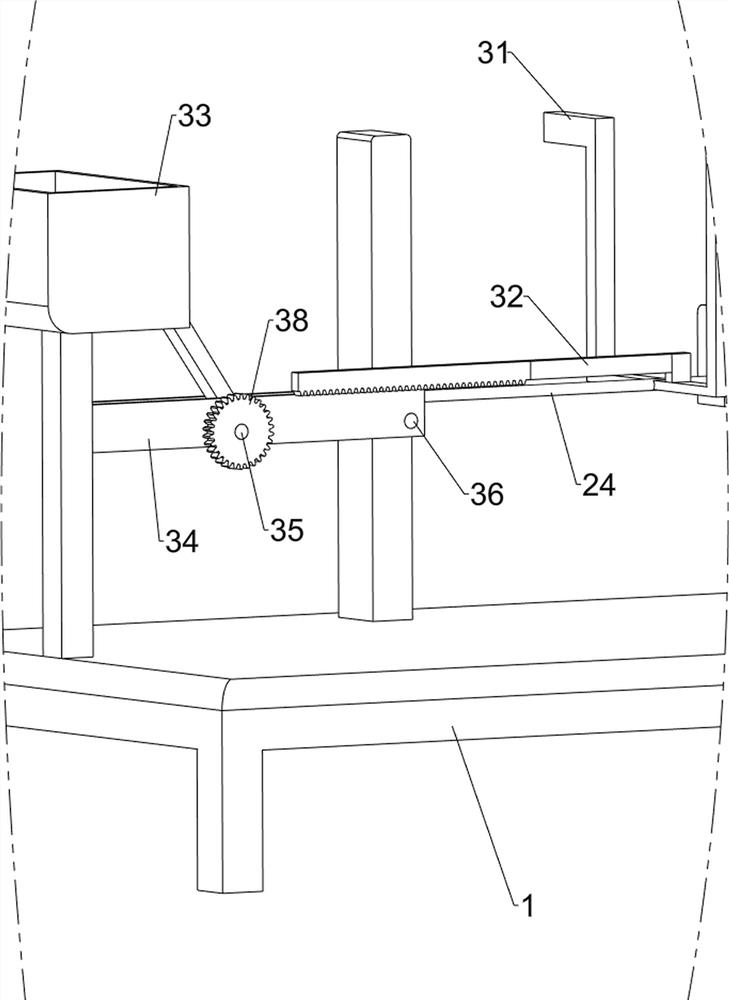

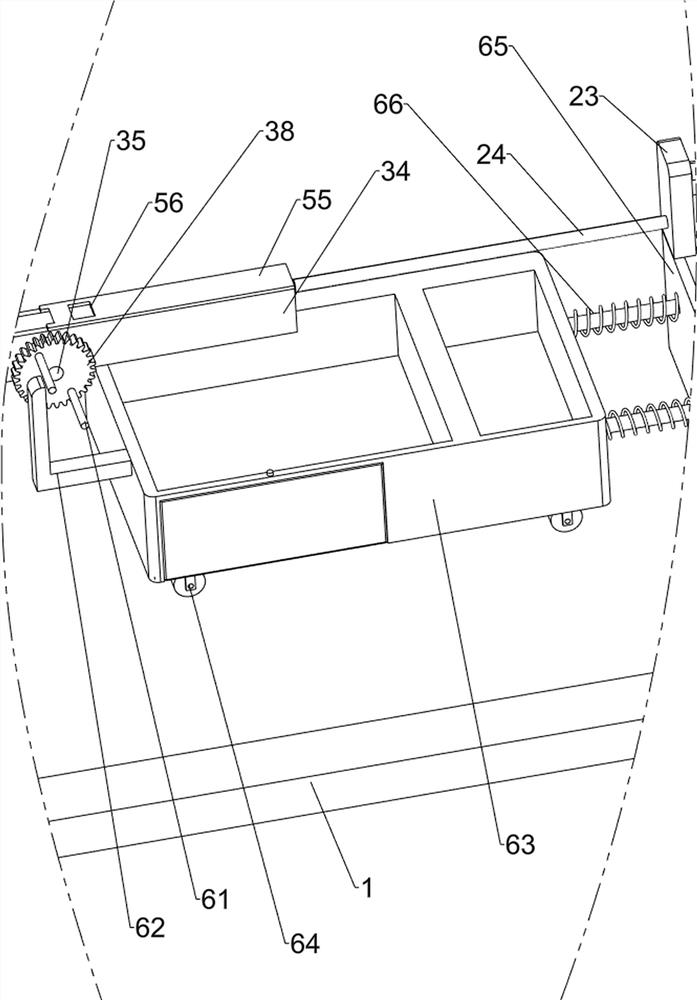

[0056] A kind of hawthorn fruit core separation equipment for food processing, such as figure 1 As shown, bottom plate 1, top core mechanism 2 and first blanking mechanism 3 are included, bottom plate 1 top rear side is provided with top core mechanism 2, bottom plate 1 top front side is equipped with first blanking mechanism 3, first blanking mechanism The mechanism 3 is in contact with the top core mechanism 2 .

[0057] When the worker needs to separate the hawthorn fruit core, the worker needs to pour an appropriate amount of hawthorn into the first feeding mechanism 3, and the first feeding mechanism 3 will transport the hawthorn to the top core mechanism 2. When the hawthorn is located on the top core After the mechanism 2 is installed, the worker can start the expansion and contraction of the top core mechanism 2, and the expansion and contraction of the top core mechanism 2 can separate the hawthorn fruit core from the hawthorn, and then the worker can remove the hawth...

Embodiment 2

[0059] In a preferred embodiment of the present invention, as figure 2 As shown, the top core mechanism 2 includes a fixed seat 21, a cylinder 22, a first fixed plate 23 and a top pipe 24, the rear side of the top of the base plate 1 is fixedly connected with a fixed seat 21, and the top of the fixed seat 21 is connected with a cylinder 22 by bolts. The telescoping rod front end of 22 is connected with the first fixing plate 23, and the lower part of the front side of the first fixing plate 23 is fixedly connected with the top pipe 24.

[0060] When the worker needs to separate the hawthorn fruit core from the hawthorn, the worker needs to first place a hawthorn on the front end of the jacking pipe 24, and then the worker needs to start the expansion and contraction of the cylinder 22, and the expansion of the telescopic rod of the cylinder 22 will drive the first fixed plate 23 to move forward. The movement of the first fixed plate 23 to the front will drive the jacking tube 2...

Embodiment 3

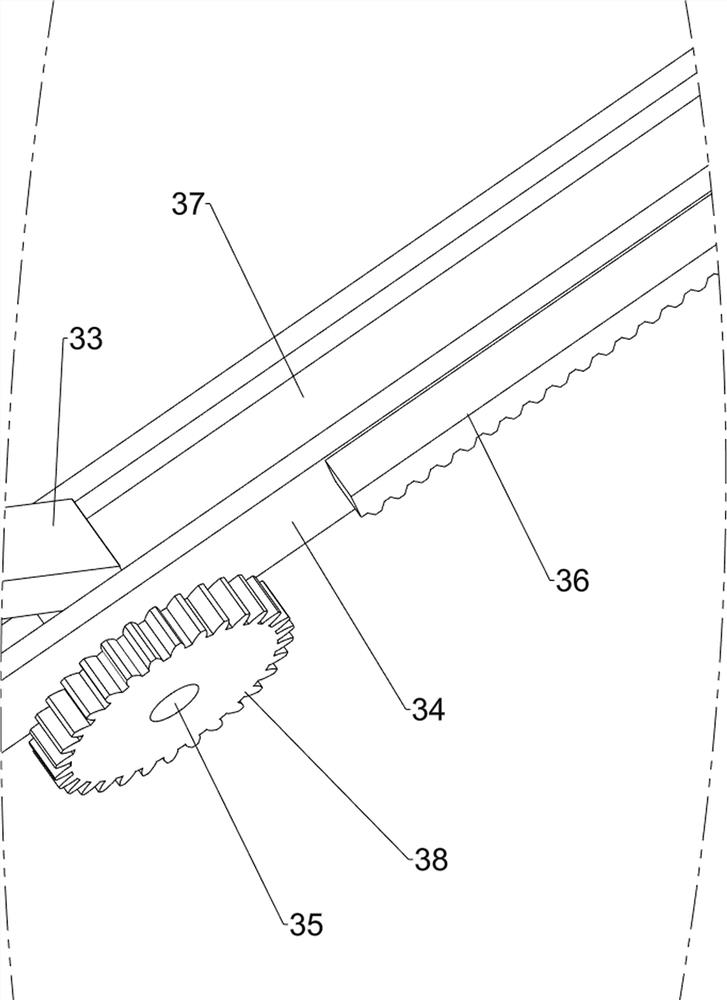

[0062] In a preferred embodiment of the present invention, as Figure 3-Figure 8 As shown, the first unloading mechanism 3 includes a fixed frame 31, a rack 32, an unloading box 33, a first baffle plate 34, a first rotating shaft 35, a second rotating shaft 36, a transmission assembly 37 and a one-way gear 38. The rear side of the tube 24 is fixedly connected with a fixed frame 31, the fixed frame 31 is equipped with a rack 32, the front side of the base plate 1 is fixedly connected with a lower material box 33, and the upper part of the front side of the base plate 1 is symmetrically provided with a first baffle plate 34. A first rotating shaft 35 is rotatably arranged between the front sides of the plates 34, and a second rotating shaft 36 is rotatably arranged on the rear side of the first baffle plate 34, and a transmission assembly 37 is connected between the first rotating shaft 35 and the second rotating shaft 36, and the transmission assembly 37 is located inside the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com