Soft package battery and preparation method thereof

A technology of soft-pack batteries and batteries, which is applied to battery components, chemical instruments and methods, circuits, etc., and can solve problems such as increasing the production cost of soft-pack batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

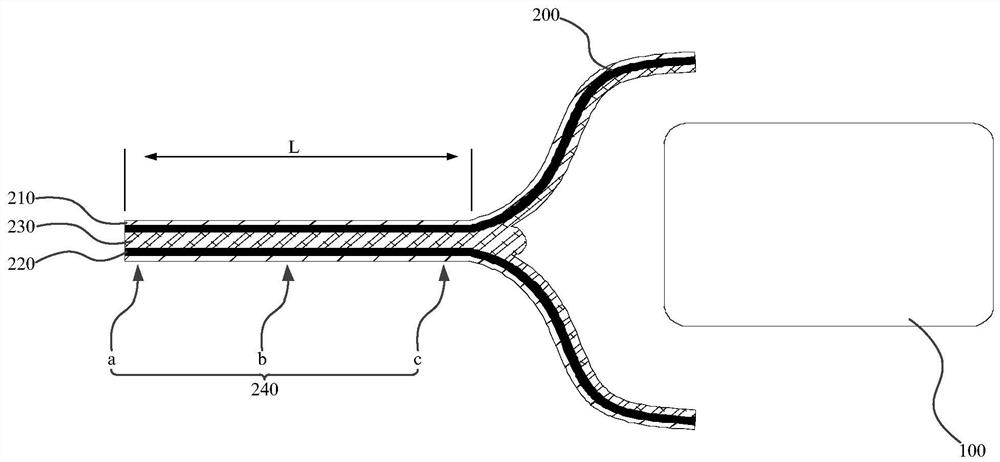

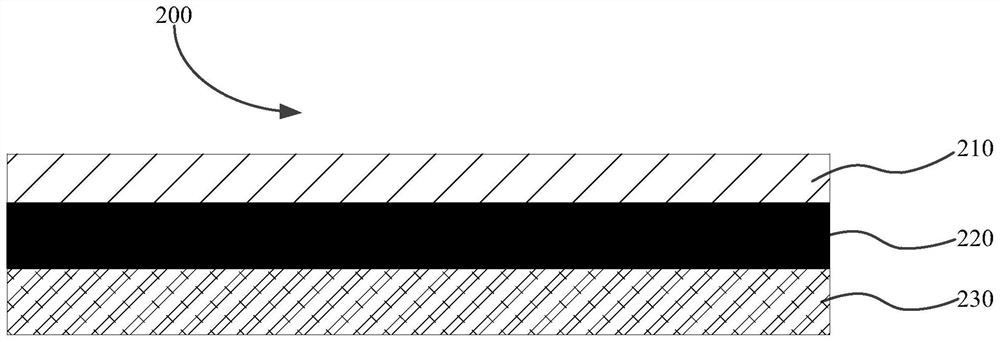

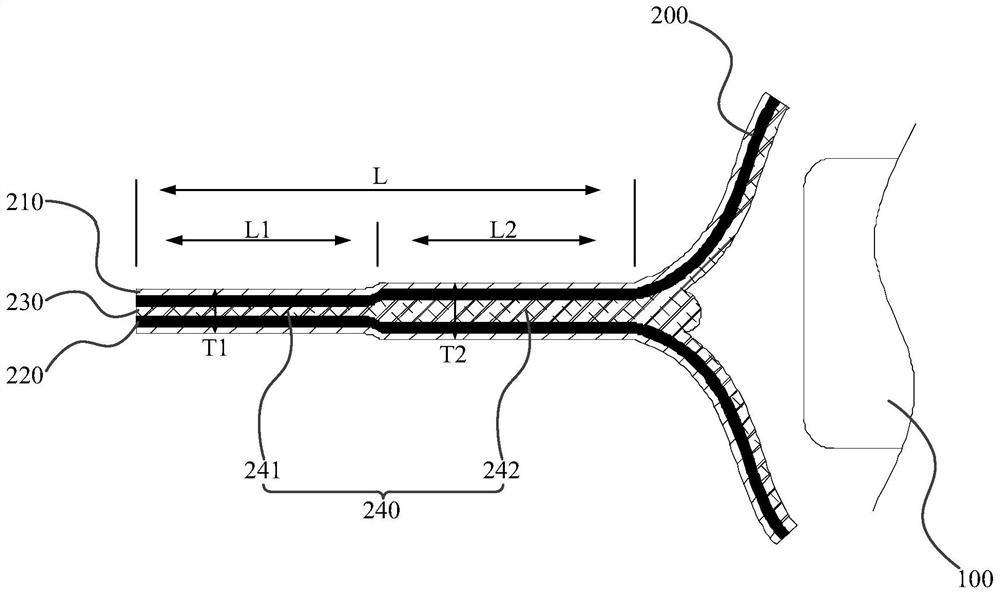

[0052] figure 2 Schematic diagram of the structure of the aluminum-plastic film provided in this embodiment; image 3 A partial structural schematic diagram of a pouch battery provided in this embodiment; Figure 4 A partial structural schematic diagram of another pouch battery provided in this embodiment; Figure 5 for Figure 4 Enlarged view of the left end of the middle packaging part; Figure 6 A schematic structural diagram of another pouch battery provided in this embodiment; Figure 7 for Figure 6 Schematic diagram of the experimental results of the aluminum plastic film structure compared with the existing technology; Figure 8 A schematic structural diagram of another pouch battery provided in this embodiment; Figure 9 A schematic structural diagram of yet another pouch battery provided in this embodiment.

[0053] Such as image 3 As shown, this embodiment provides a pouch battery, including a battery cell 100 and an aluminum-plastic film 200 covering the ...

Embodiment 2

[0074] On the basis of Embodiment 1, this embodiment provides a method for preparing a pouch battery, so that the thickness of the PP layer at the end of the packaging part away from the battery cell is smaller than the thickness of the PP layer at the end of the packaging part facing the battery cell, thereby improving the performance of the pouch battery. waterproof performance.

[0075] The preparation method of the pouch battery provided in this embodiment includes: providing a cell and an aluminum-plastic film, and punching the aluminum-plastic film to form a pit for accommodating the cell. It is easy to understand that the shape and size of the pit are the same as that of the cell. Matching, place the battery inside the pit.

[0076] After the aluminum-plastic film is folded in half, the edges of the upper and lower layers of aluminum-plastic film are thermally sealed by using a head. Exemplarily, the head includes an upper head and a lower head, two layers of aluminum-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com