Heating pipe temperature monitoring device and method

A heating tube temperature and monitoring device technology, applied in the direction of temperature control, non-electric variable control, control/regulation system, etc., can solve the problems of inaccurate temperature measurement, exposed temperature sensor, and inability to accurately control temperature, etc., to achieve simple structure, Achieving aging problems and improving heating safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

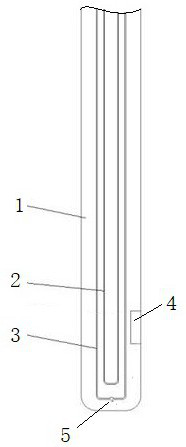

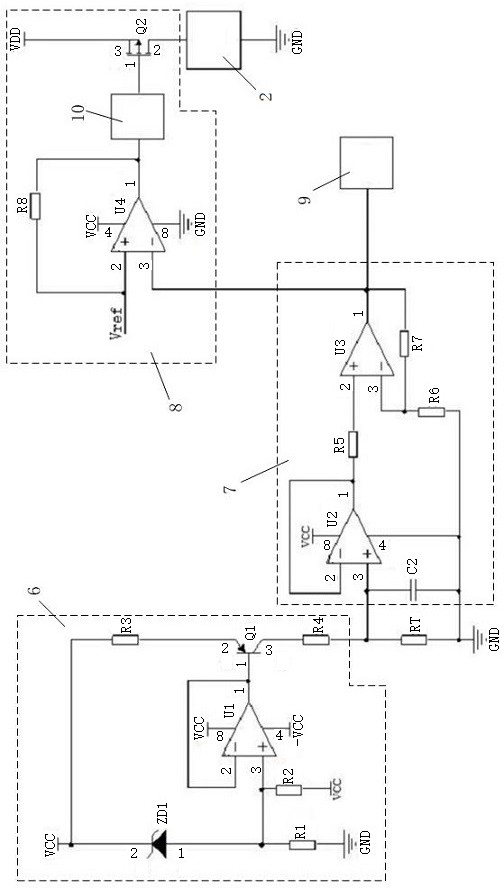

[0038] Such as figure 1 As shown, the present embodiment provides a heating tube temperature monitoring device, in which a heating wire 2 and a temperature sensor 4 are arranged in the heating tube 1. The difference from the prior art is that the device is also provided with a metal wire 3 in the heating tube 1. The wire 3 is arranged around the heating wire 2 . For example, the heating wire 2 is arranged in a rectangular shape inside the heating tube 1 , and the metal wire 3 is another rectangular structure surrounding the heating wire 2 outside the rectangle.

[0039] The temperature sensor 4 is electrically connected with the heating controller 9 to realize single-point temperature measurement in the heating tube 1 . The heating controller 9 is also electrically connected to an alarm to realize an over-temperature alarm or other abnormal alarms.

[0040] In this embodiment, based on the characteristics of the positive temperature coefficient / negative temperature coefficie...

Embodiment 2

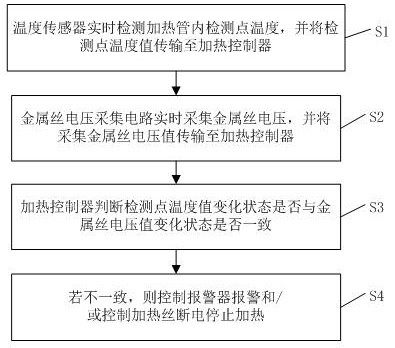

[0057] Such as image 3 As shown, on the basis of the first embodiment, this embodiment provides a temperature monitoring method for the heating tube 1, including the following steps:

[0058] S1, the temperature sensor 4 detects the temperature of the detection point in the heating tube 1 in real time, and transmits the temperature value of the detection point to the heating controller 9;

[0059] S2, the wire voltage acquisition circuit 7 collects the voltage of the wire 3 in real time, and transmits the collected voltage value of the wire 3 to the heating controller 9;

[0060] S3, the heating controller 9 judges whether the change state of the temperature value of the detection point is consistent with the change state of the voltage value of the metal wire 3;

[0061] S4, if inconsistent, control the alarm to give an alarm and control the heating wire 2 to cut off the power to stop heating.

[0062] Wherein the heating controller 9 judges whether the change state of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com