A heating tube temperature monitoring device and method

A technology of heating tube temperature and monitoring device, applied in temperature control, control/regulation system, non-electric variable control and other directions, can solve the problems of inaccurate temperature measurement, exposed temperature sensor, inability to accurately control temperature, etc., to achieve aging problems , The structure is simple, the effect of improving the heating safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

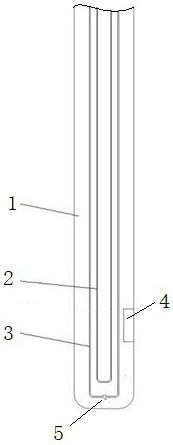

[0038] like figure 1 As shown, this embodiment provides a heating tube temperature monitoring device. A heating wire 2 and a temperature sensor 4 are arranged in the heating tube 1. Different from the prior art, this device is also provided with a metal wire 3 in the heating tube 1. The wire 3 is arranged around the heating wire 2 . For example, if the heating wire 2 is arranged in a rectangle inside the heating tube 1 , the metal wire 3 is another rectangular structure outside the rectangle surrounding the heating wire 2 .

[0039] The temperature sensor 4 is electrically connected with the heating controller 9 to realize single-point temperature measurement in the heating tube 1 . The heating controller 9 is also electrically connected to an alarm to realize over-temperature alarm or other abnormal alarm.

[0040] Based on the positive temperature coefficient / negative temperature coefficient of the metal wire 3 (the resistance value of the metal wire 3 increases / decreases ...

Embodiment 2

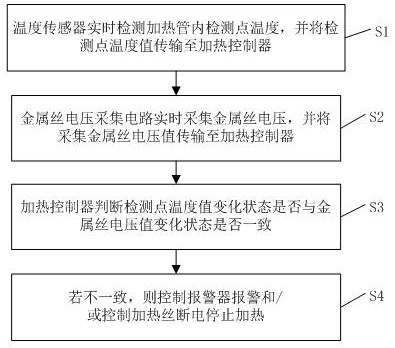

[0057] like image 3 As shown, on the basis of the first embodiment, this embodiment provides a temperature monitoring method for the heating pipe 1, which includes the following steps:

[0058] S1, the temperature sensor 4 detects the temperature of the detection point in the heating pipe 1 in real time, and transmits the temperature value of the detection point to the heating controller 9;

[0059] S2, the wire voltage collection circuit 7 collects the voltage of the wire 3 in real time, and transmits the collected voltage value of the wire 3 to the heating controller 9;

[0060] S3, the heating controller 9 judges whether the change state of the temperature value of the detection point is consistent with the change state of the voltage value of the metal wire 3;

[0061] S4, if it is inconsistent, the alarm will be controlled to give an alarm and the heating wire 2 will be powered off to stop heating.

[0062] The heating controller 9 judges whether the change state of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com