Axial flow type check valve

A check valve, axial flow technology, applied in valve details, control valves, valve devices, etc., can solve problems such as valve damage, reduced service life, and high impact force on the sealing surface of the valve seat, to achieve reliable closing and sealing, Improve service life and prevent water hammer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

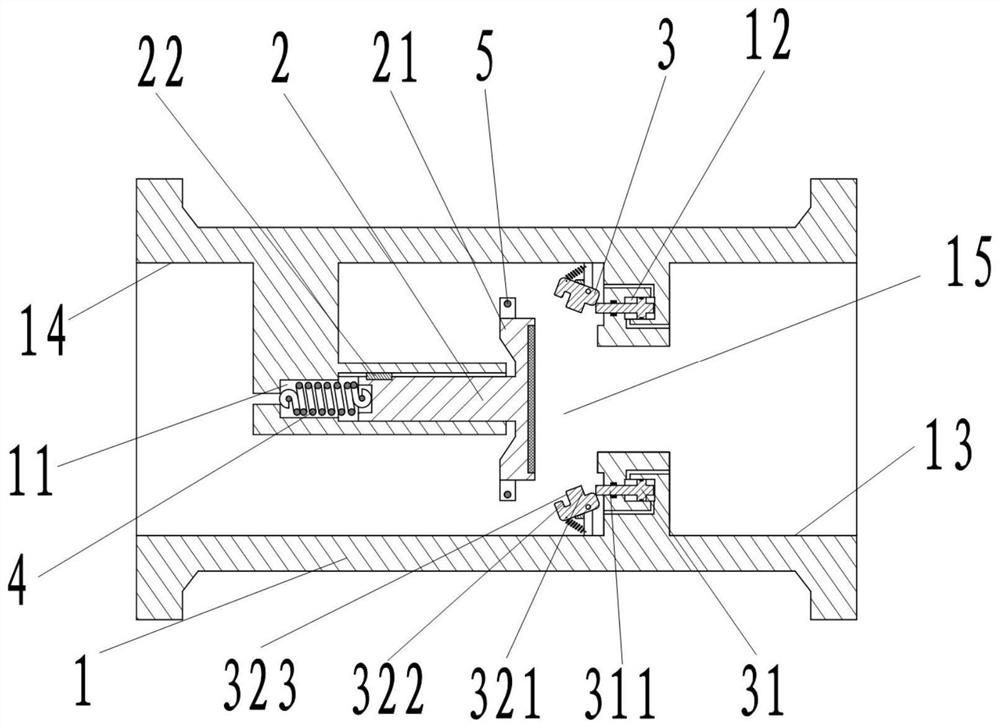

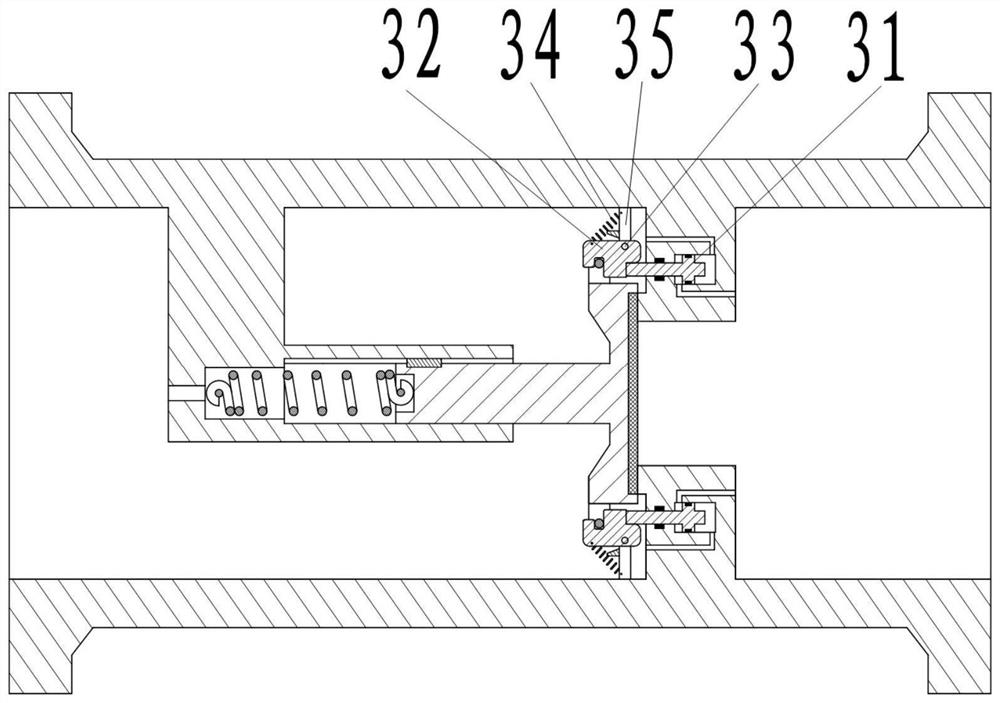

[0015] Such as Figure 1-2 Shown is a preferred embodiment of the present invention.

[0016] An axial flow check valve, comprising a valve body 1, a valve core 2, a plurality of locking components 3, a buffer tension spring 4 and a plurality of locking rods 5; the valve body 1 is provided with a valve chamber 15, the The right side of the valve body 1 is provided with an inlet pipe 13 communicating with the valve chamber 15, and the left side of the valve body 1 is provided with an outlet pipe 14 communicating with the valve chamber 15; The first installation chamber 11 connected by the tube 14, the valve core 2 is slidingly connected in the first installation chamber 11 through the flat key 22, and the right side of the valve core 2 is provided with a valve disc 21; one end of the buffer spring 4 is fixedly connected to the On the valve bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com