Synchronous toothed belt conveying mechanism

A technology of synchronous toothed belt and conveying mechanism, which is applied in the direction of conveyor, transportation and packaging, etc. It can solve the problems of complicated process, heavy disassembly and installation workload, and inability to apply synchronous toothed belt conveying mechanism, so as to improve the installation accuracy, The effect of simple operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

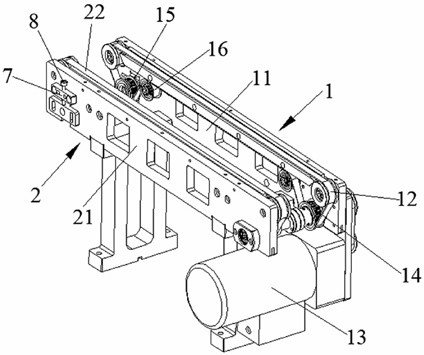

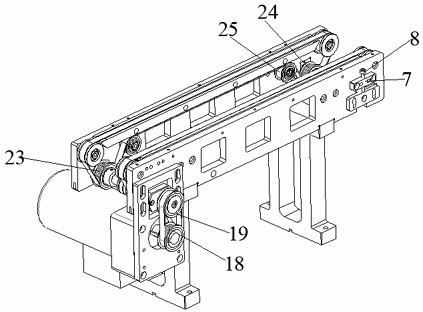

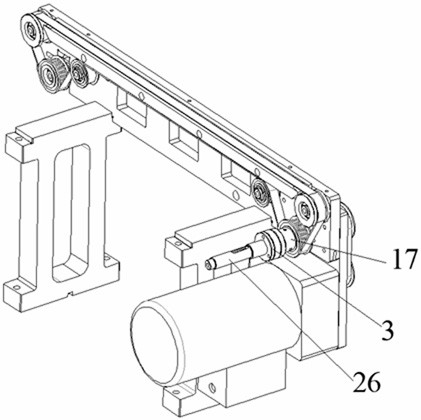

[0037] see Figure 1 to Figure 5 , a synchronous toothed belt conveying mechanism, comprising a first conveying mechanism 1 and a second conveying mechanism 2 arranged in parallel and symmetrically;

[0038] The first conveying mechanism includes a first conveying profile 11, a first synchronous toothed belt 12, a first driving mechanism and a first driven mechanism; the upper part of the first conveying profile has a first conveying channel, and the first The synchronous toothed belt penetrates the first conveying channel and forms a first conveying surface above the first conveying profile; the first driving mechanism includes a motor 13 and a first driving wheel 14, and the first driven mechanism includes At least one first driven wheel 15; one end of the first synchronous toothed belt is sleeved on the first driving wheel, the other end is sleeved on the first driven wheel, and at least one first The tensioning wheel 16 forms a belt transmission structure; the first tensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com