Segment type multistage centrifugal pump

A centrifugal pump, segmental technology, applied in the field of segmental multi-stage centrifugal pumps, can solve problems such as troublesome and inconvenient processes, affecting the installation accuracy of internal parts of centrifugal pumps, etc., to improve the speed of installation and disassembly, improve the efficiency of maintenance and replacement, Effect of preventing reduction in mounting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

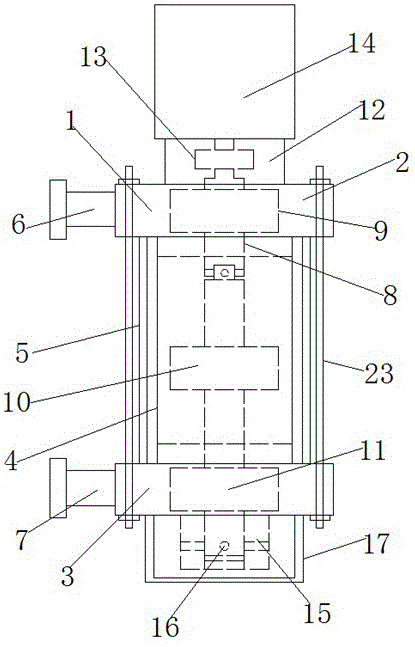

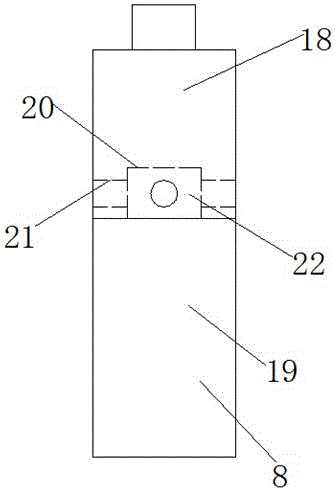

[0019] Reference Figure 1-3 , A segmented multi-stage centrifugal pump, comprising a housing 1, the housing 1 is composed of a discharge end fixing frame 2, a suction end fixing frame 3 and a circular arc connecting block 4, one end of the discharge end fixing frame 2 is installed with a circular arc Connecting block 4, the end of the arc connecting block 4 away from the discharge end fixing frame 2 is equipped with a suction end fixing frame 3, the outer side of the arc connecting block 4 is sleeved with a semi-arc protective cover 5, one of the discharge end fixing frame 2 A drain pipe 6 is installed on the side, a suction pipe 7 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com