Engine trim cover mounting bracket

A technology for mounting brackets and decorative covers, which is applied in the field of auto parts, and can solve problems such as the inconsistency between the strength of the mounting bracket and the manufacturing cost, and achieve the effects of avoiding the reduction of mounting accuracy, simple manufacturing process, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples.

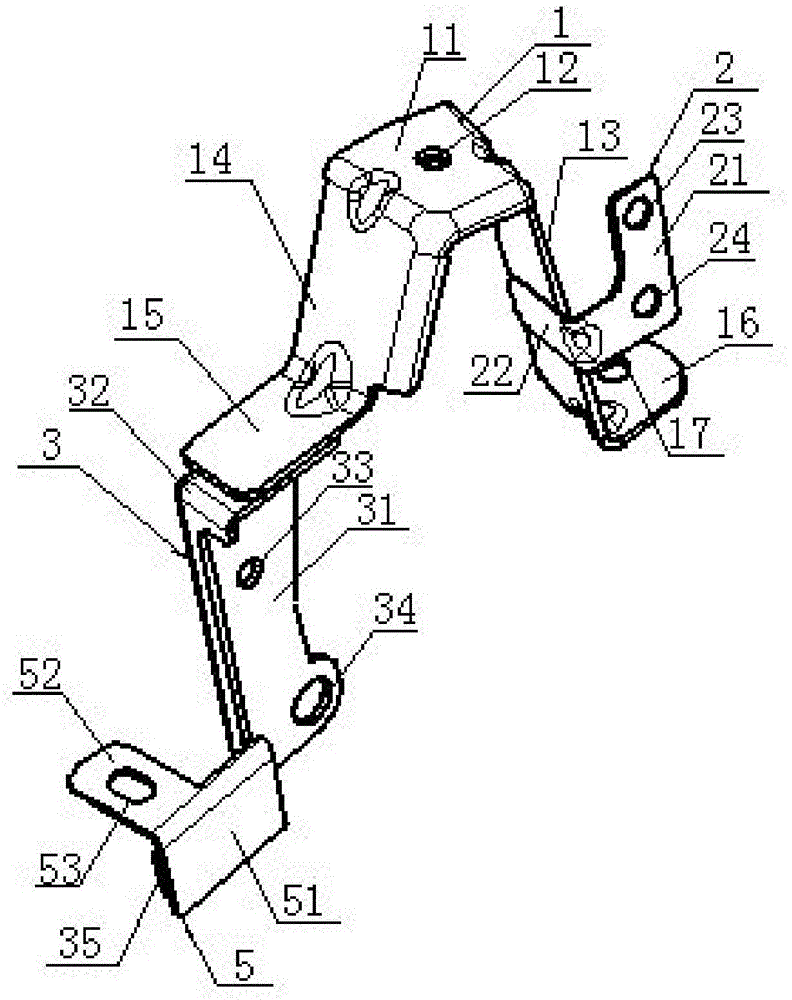

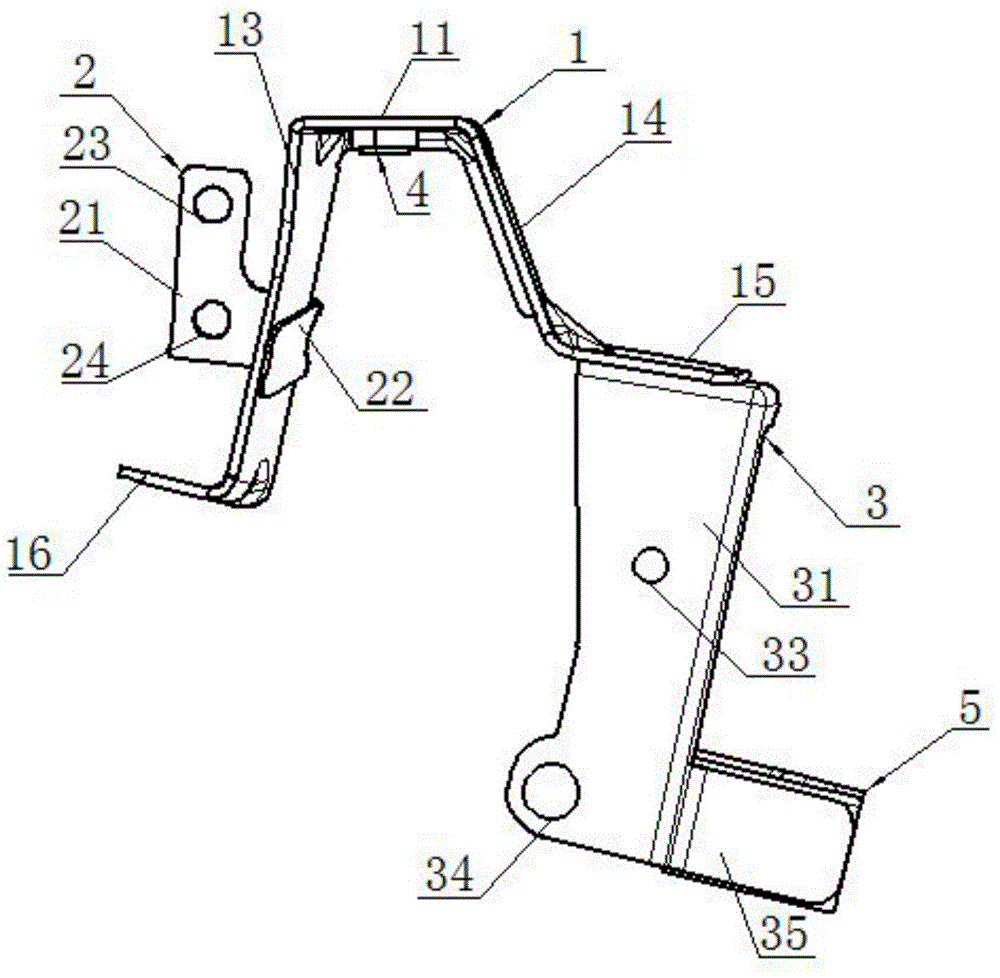

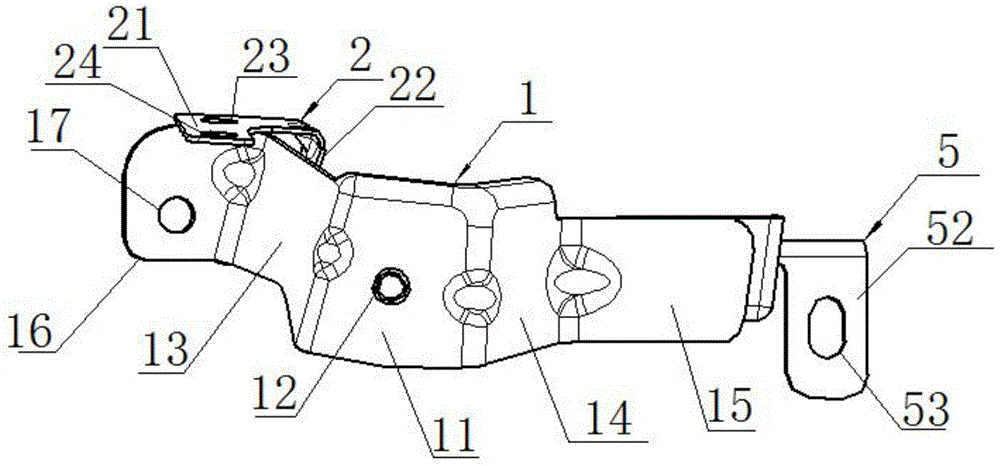

[0031] Such as figure 1 , 2 , Shown in 3, a kind of engine decorative cover mounting bracket, comprises upper bracket 1, wiring harness bracket 2, lower bracket 3, nut 4 and mounting plate 5;

[0032] The upper bracket 1 includes a bottom plate 11, the two opposite edges of the bottom plate 11 are longitudinally bent in the same direction to form a first side plate 13 and a second side plate 14, the first side plate 13 and the second side plate 14 The ends extend laterally in opposite directions to form a first flat wing 15 and a first flat wing 16 , the bottom plate 11 is provided with a first mounting hole 12 , and the first side plate flat wing 16 is provided with a second mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com