Backing tape supporting device for laying thermosetting composite material prepreg tape

A composite material and support device technology, which is applied in the field of advanced composite material automated manufacturing equipment to achieve the effect of simplifying functional requirements and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

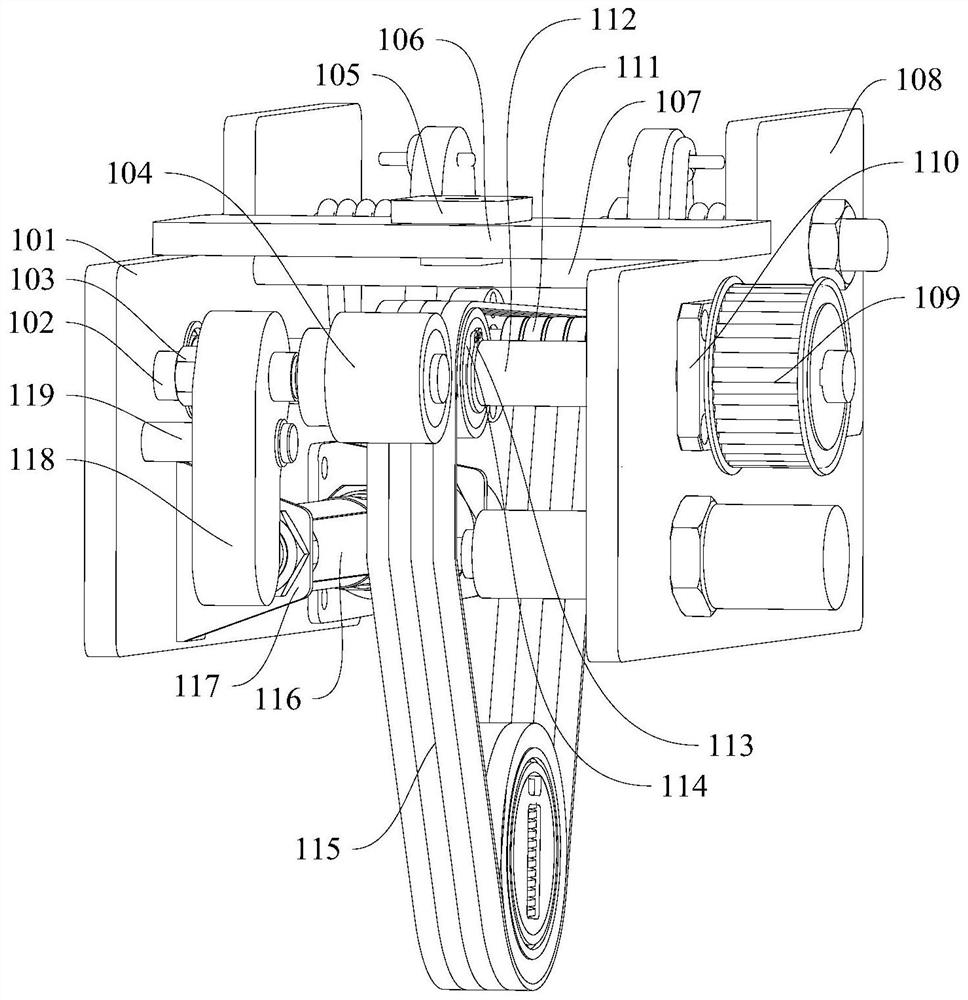

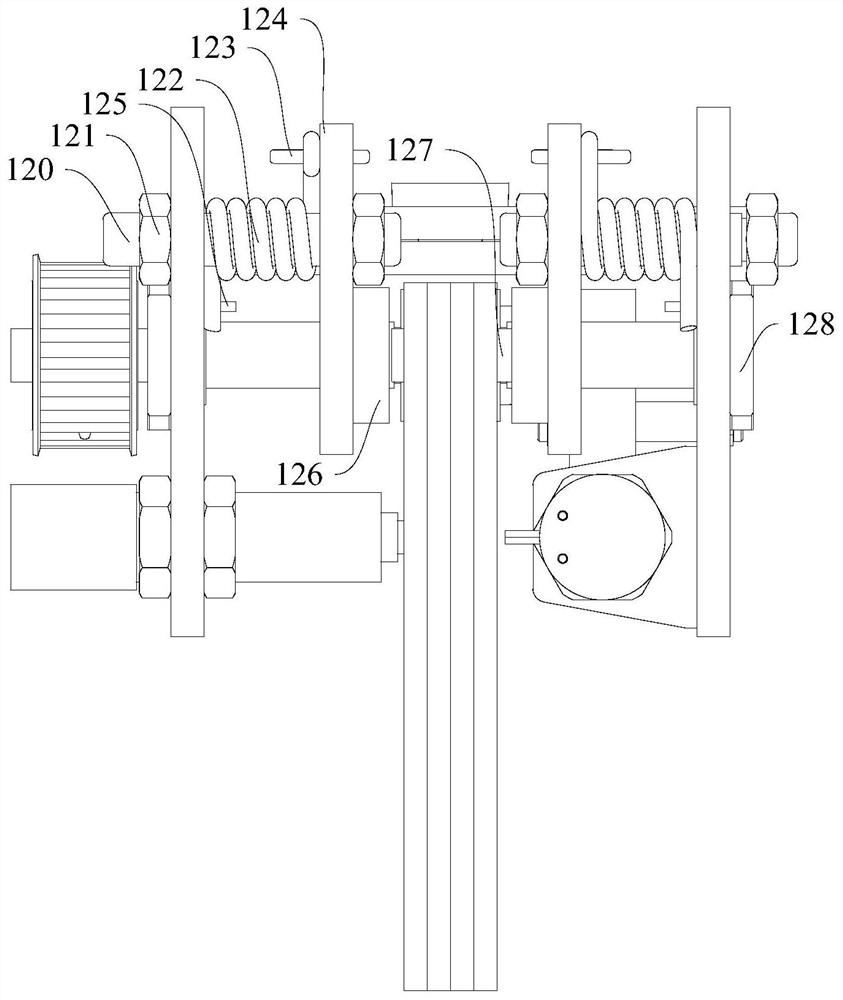

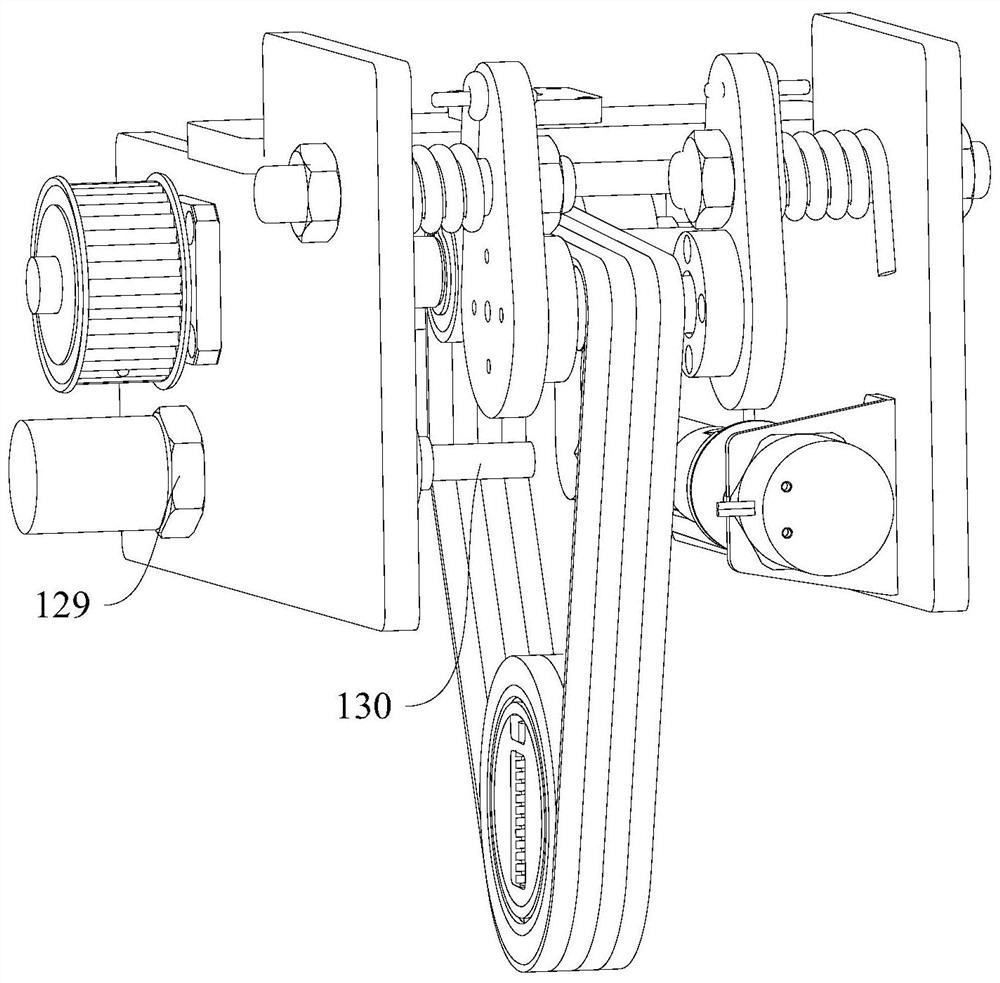

[0036] see Figure 1 to Figure 3 , the backing tape supporting device for laying thermosetting composite prepreg tape in this embodiment includes a transmission mechanism, a pressure bonding mechanism, an automatic tensioning mechanism and a tension detection mechanism.

[0037]The transmission mechanism is used to support the backing belt, and one end of the backing belt 115 of the cotton canvas flat belt covered with heat-resistant rubber is sleeved on the backing belt driving wheel 114, and the backing belt driving wheel 114 is fixed on the transmission shaft 112, and Axial positioning is carried out by means of a circlip 113 . A timing pulley 109 is installed on the extended end of the transmission shaft 112 outside to provide power input. The two ends of the transmission shaft 112 are installed on the front support plate 101 and the rear support plate 108 through the front belt cover bearing 110 and the rear belt cover bearing 128 . In the process of unwinding and conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com