Segment embedded part fixing base and segment forming method

A technology for fixing the base and embedded parts, which is applied to ceramic molding machines, auxiliary molding equipment, manufacturing tools, etc., can solve the problems of easy loosening of plastic bases, grout adhesion in hoisting holes, and influence of hoisting, so as to prevent cement The slurry penetrates into the plugged hole, the maintenance cost is low, and the effect of reducing the later cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. The described embodiments are only illustrations and explanations of the present invention, and do not constitute the only limitation of the present invention.

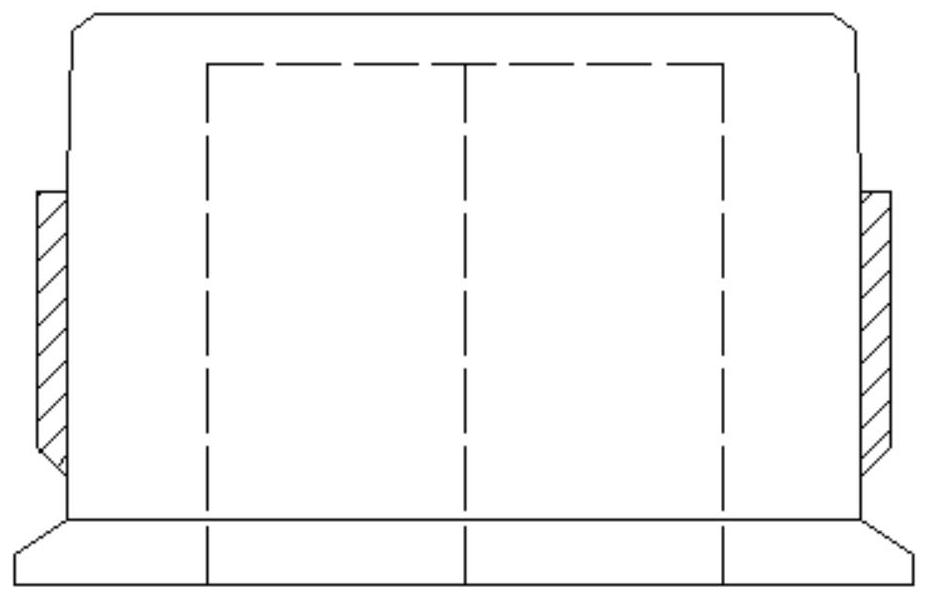

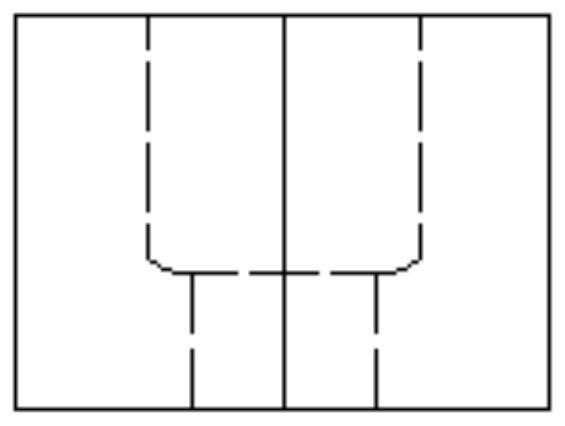

[0021] Such as Figure 1-Figure 2 As shown, the fixed base of the present invention includes a first matching piece and a second matching piece. The first matching piece is provided with an external thread that matches the hoisting hole of the crane. The first matching piece is provided with a hexagonal hole; the second matching piece is cylindrical and The inner hole of the step is provided, and the second supporting part is fixedly arranged on the steel mold.

[0022] A method for forming a segment, comprising the steps of:

[0023] The first step is to inspect the product before the hoisting hole enters the site. It is required that the appearance of the product is qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com