Transformer tap screw tightening and loosening tool

A technology for transformer taps and tools, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of increased operation difficulty, dislocation, inconvenient force application, etc., to reduce the risk of screw jamming, reduce the possibility of damage, operation convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

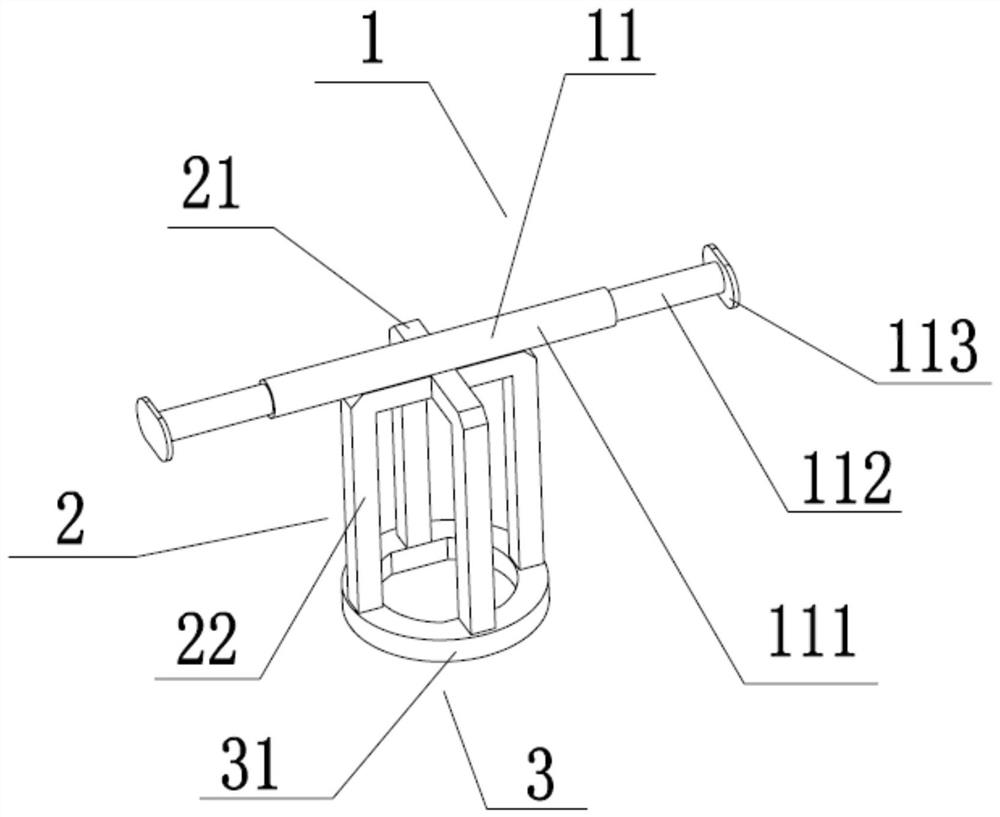

[0028] Such as figure 1 Shown is the first embodiment of a transformer tap screw tightening tool of the present invention, which includes a force applying part 1, a connecting part 2, a fixing part 3, and a force applying part connected sequentially from top to bottom to make the whole tool rotate. 1 is a handle 11 arranged symmetrically with respect to the central axis of the connecting part 2, and the handle 11 is a telescopic structure.

[0029] As an embodiment of the present invention, the handle 11 can perform telescopic movement along the length direction. Different from the principle of the wine corkscrew that stretches and moves along the arc, the present invention realizes the tightness of the tap screw through the rotation of the handle 11, and the handle 11 that can be stretched along the straight line can extend the force as much as possible in a place with enough space. Arm, to achieve labor-saving effect.

[0030] As an embodiment of the present invention, the...

Embodiment 2

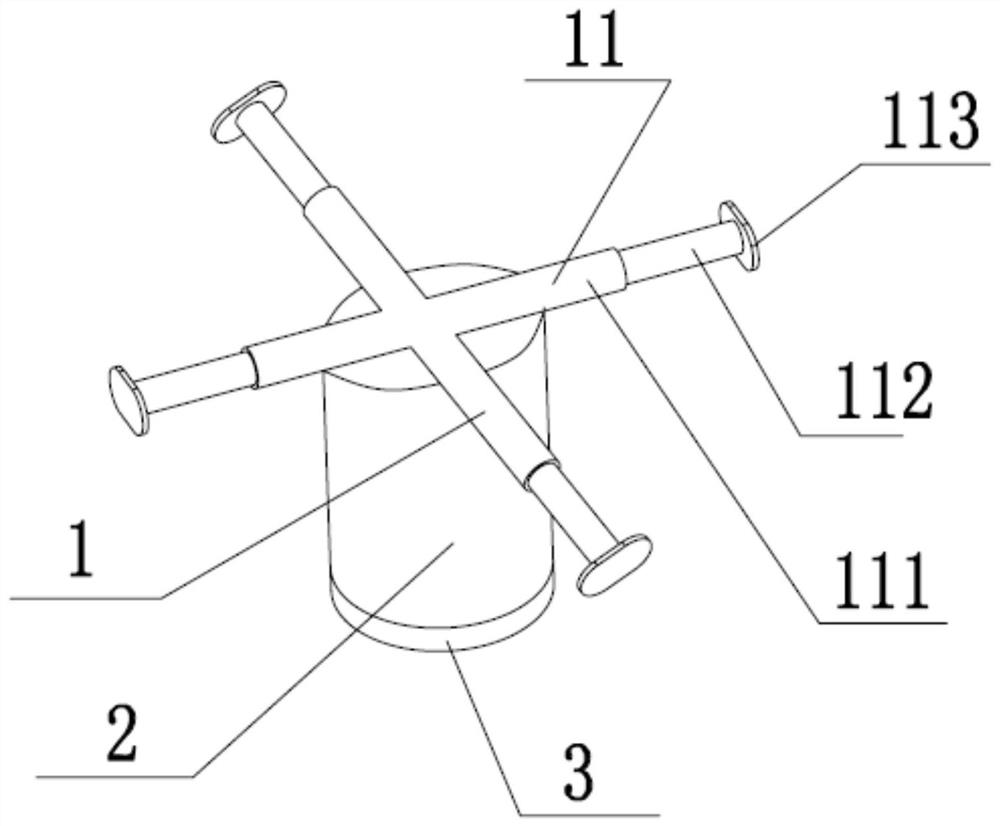

[0039] Such as figure 2The above is the second embodiment of a transformer tap screw tightening tool according to the present invention. This embodiment is similar to Embodiment 1, except that there are four handles 11 in this embodiment. The four handles 11 are vertical in pairs, that is, the four handles are on a plane, and the two adjacent handles are arranged vertically. When the fixing part 3 rotates to different angles, different handles 11 can be applied with force, further improving the convenience of operation.

[0040] As an embodiment of the present invention, the connecting part 2 is a cylindrical shell provided with a hollow cavity, one end of the cylindrical shell is open, the connecting part 2 is connected to the fixed part 3 close to the open end, and the connecting part 2 is far away from the open end and the handle 11 connections. The connecting part 2 forms a whole, which covers the fixed part 3 as a whole like a bell jar. On the one hand, it can facilita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com