A friction nanogenerator based on fiber sliding and its preparation method

A nano-generator and fiber technology, applied in triboelectric generators, carbon fiber, fiber processing and other directions, can solve the problems of low power output, power generation performance needs to be improved, and no advantages are shown, and achieve the effect of improving power generation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

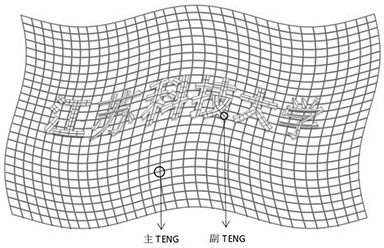

[0041]A frictional nanogenerator based on fiber sliding, including a main TENG and a secondary TENG, the main TENG is a cloth-like device woven from positive and negative fibers, and the positive fiber is wrapped and insulated on the surface of the positive conductive carbon fiber Resin film, the negative electrode fiber is coated with a layer of conductive metal on the basis of the positive electrode fiber, the positive electrode conductive carbon fiber and one end of the negative electrode conductive carbon fiber of the negative electrode fiber are respectively connected to the load, the positive electrode of the rectifier is connected to one end of the positive electrode conductive carbon fiber, The negative pole of the rectifier is connected to the conductive metal plating.

[0042] The sub-TENG is braided by metal-plated conductive textile wire and insulating resin-wrapped carbon fiber, in which the metal-coated conductive textile wire is used as the positive electrode, an...

Embodiment 2

[0045] The difference from Example 1 is that a triboelectric flag containing only the main TENG part is used. The entire flag uses CF@PDMS with a diameter of 0.8mm and conductive braided wire as the textile material. The size of the production is 20cm×30cm. The maximum output voltage generated when blowing at a wind speed of / s is 98V. It can be concluded that the charge generated by the friction between the secondary TENG materials is supplied to the main TENG, which can effectively increase the output voltage of the power generation device.

Embodiment 3

[0047] The difference from Example 1 is that under the condition of not being affected by the external wind force, a flag with a diameter of 0.8mm and an area of 20cm×30cm is used, in which the area of the main TENG is 20cm×20cm, and the area of the secondary TENG is 10cm ×20cm. The wind speeds of 7m / s, 14m / s, and 21m / s respectively blow the generators, and the maximum output voltages generated are 52V, 107V, and 164V, respectively. Under the influence of different wind forces, the deformation and vibration frequency of the flag are different, and the voltage generated by sliding between the friction materials is also different. The magnitude of the wind force has a relatively high linear relationship with the magnitude of the output voltage. Through this characteristic, the technical solution of the present invention is also suitable for monitoring the magnitude of the wind force in the natural environment.

[0048] As an efficient mechanical energy collection device, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com