Flexible job shop scheduling method based on multistage neighborhood structure and hybrid genetic algorithm

A hybrid genetic algorithm and flexible operation technology, applied in the field of job shop scheduling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

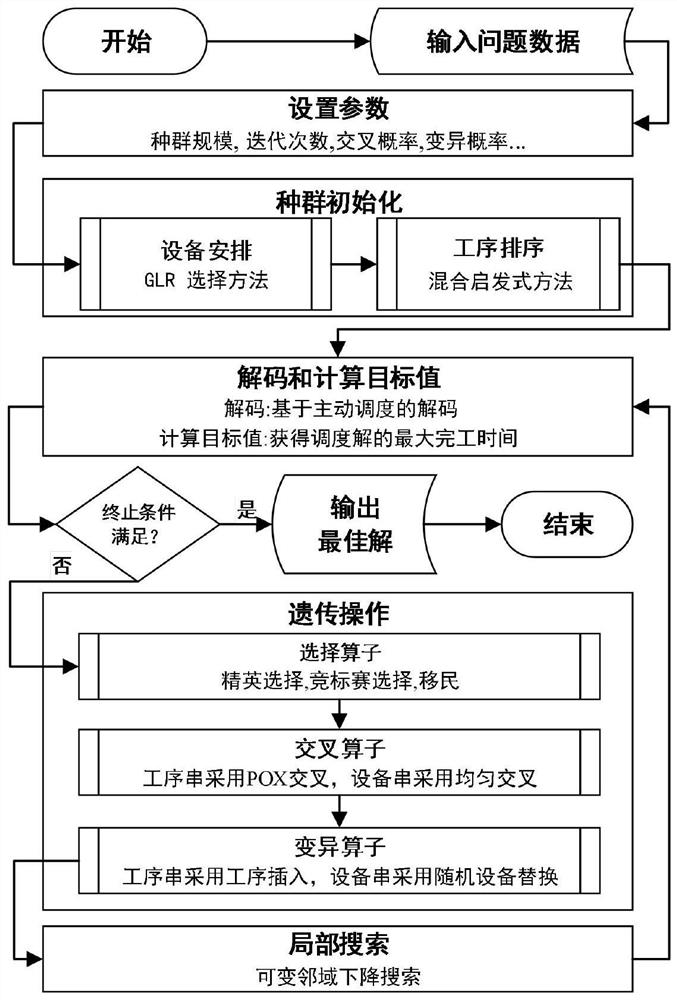

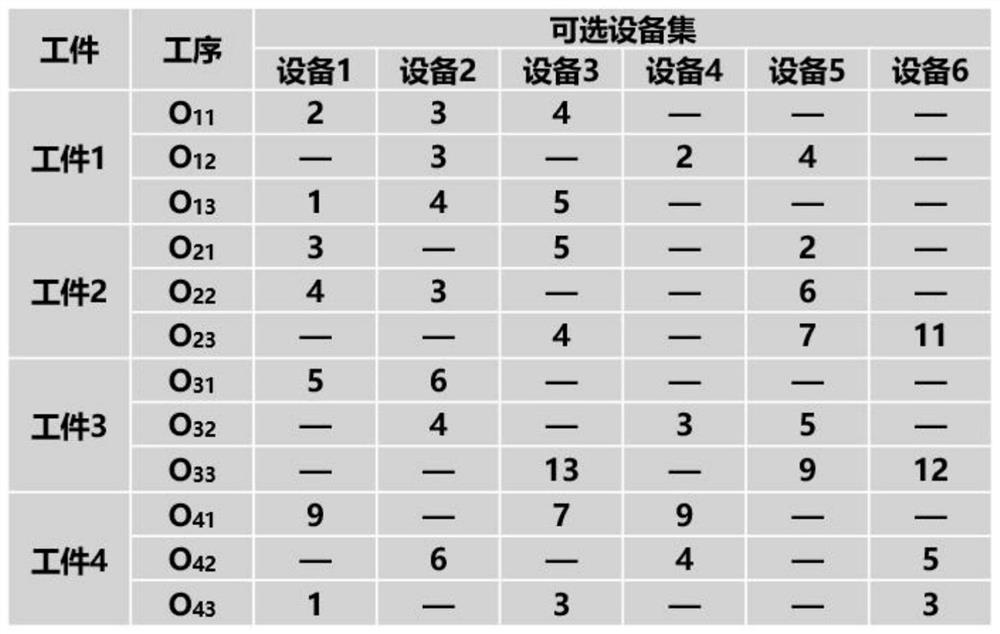

[0059] The present invention is a flexible job shop scheduling method based on a new hybrid genetic algorithm, which combines a hybrid heuristic initialization method and multi-level neighborhood search based on key processes to solve the flexible job shop scheduling problem. The algorithm flow is as follows figure 1 shown. Now with figure 2 The example problem shown is illustrated.

[0060] Step 1: Enter the basic data of the problem, including the number of workpieces 4, the number of equipment 6, and the processing time of each process of each workpiece on optional equipment.

[0061] Step 2: Set the algorithm parameters: the population size is 50, the crossover probability is 0.8, the mutation probability is 0.1, and the number of iterations is 200.

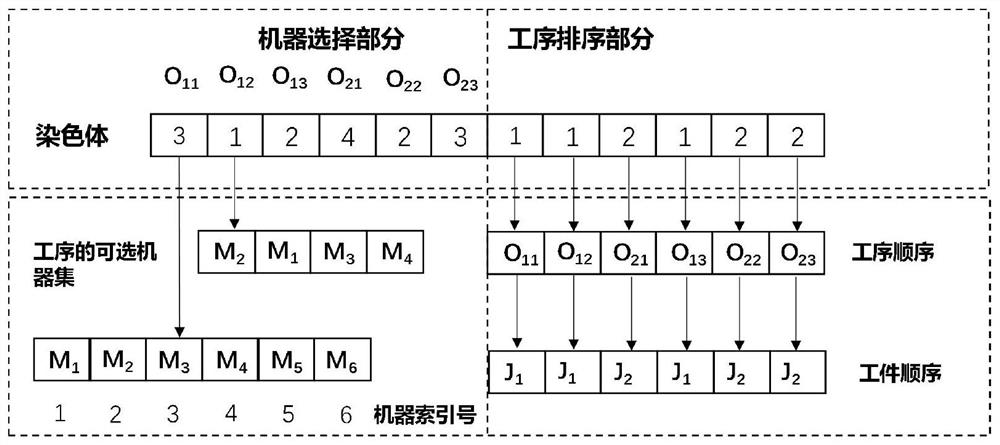

[0062] Step 3: Generate an initialization population, namely: 50 initial individuals, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com