A method and device for quantitatively measuring cavitation strength in clear water or sandy water

A quantitative measurement and clear water technology, which is applied in the field of analysis and testing, can solve the problems affecting the accuracy of the experiment, and achieve the effect of simple test equipment, high sensitivity and precision, and short cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

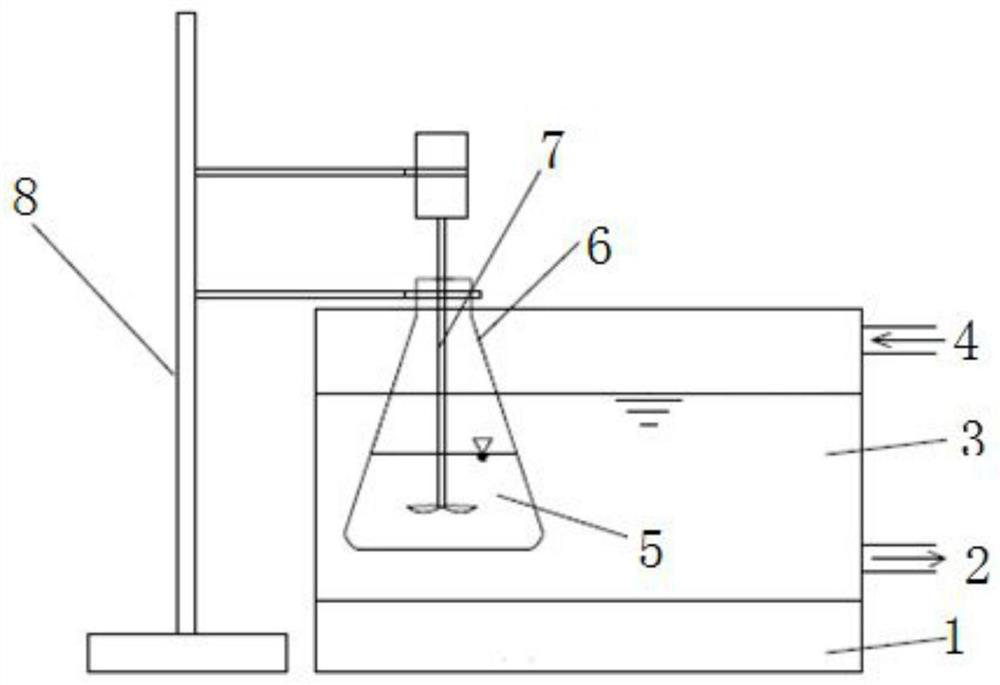

Method used

Image

Examples

Embodiment 1

[0044] (1) Prepare FeSO with a concentration of 10mmol / L 4 The solution is 500mL, and the concentration of dilute sulfuric acid in the solution is ≥5mmol / L.

[0045] (2) Transfer all the prepared solutions into the Erlenmeyer flask, and install the test device.

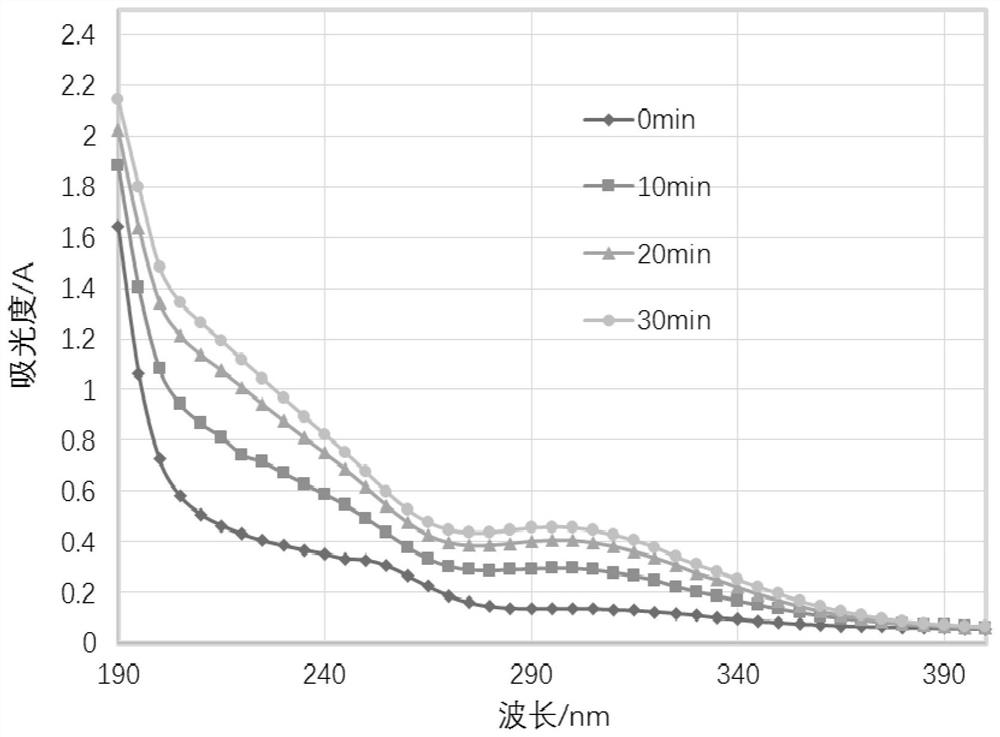

[0046] (3) Turn on the ultrasonic and stirring devices and start timing at the same time. After 30 minutes, take the solution supernatant in the conical flask and add it to a quartz cuvette to measure the absorbance at the incident light wavelength of 300 nm. The result is 0.358.

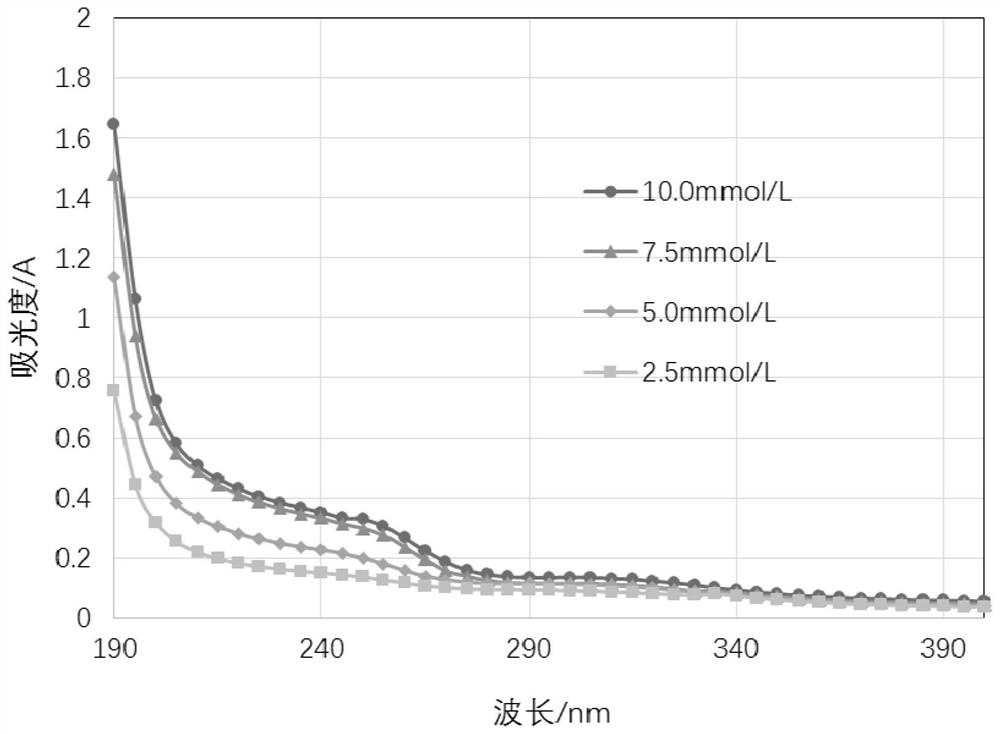

[0047] As a control, 500 mL of FeSO with a concentration of 7.5, 5.0, and 2.5 mmol / L were prepared respectively. 4 Solution is tested and compared with Example 1, the results are as follows figure 2 shown. From figure 2 It can be concluded that in the wavelength range of 190nm-400nm, with FeSO 4 As the concentration of the solution decreases, the absorbance also gradually decreases; the absorbance changes greatly in the wavelength ra...

Embodiment 2

[0050] (1) Prepare FeSO with a concentration of 10mmol / L 4 The solution is 500mL, and the concentration of dilute sulfuric acid in the solution is ≥5mmol / L.

[0051] (2) Transfer all the prepared solution to the Erlenmeyer flask. Weigh 1.0 g of quartz sand particles with a particle size of 40-60 μm, and add it into the Erlenmeyer flask so that the sand content of the solution is 2.0 g / L. Then install and fix the test device.

[0052] (3) Turn on the ultrasonic and stirring devices and start timing at the same time. After 30 minutes, take the solution supernatant in the conical flask and add it to a quartz cuvette to measure the absorbance at 300nm incident light wavelength, and the result is 0.670.

Embodiment 3

[0054] (1) Prepare FeSO with a concentration of 10mmol / L 4 The solution is 500mL, and the concentration of dilute sulfuric acid in the solution is ≥5mmol / L.

[0055] (2) Transfer all the prepared solution to the Erlenmeyer flask. Weigh 2.0 g of quartz sand particles with a particle size of 40-60 μm, and add it into the Erlenmeyer flask so that the sand content of the solution is 4.0 g / L. Then install and fix the test device.

[0056] (3) Turn on the ultrasonic and stirring devices and start timing at the same time. After 30 minutes, take the supernatant of the solution in the conical flask, add it to a quartz cuvette and measure the absorbance at 300nm incident light wavelength, and the result is 0.714.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com