A hydrogen filling device with gas leak detection function

A filling device and hydrogen technology, which are applied in the methods of container discharge, equipment loaded into pressure vessels, gas treatment/storage effects, etc., can solve the problems of hydrogen leakage waste, inability to detect hydrogen leakage, explosion, etc., to prevent hydrogen leakage leaked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

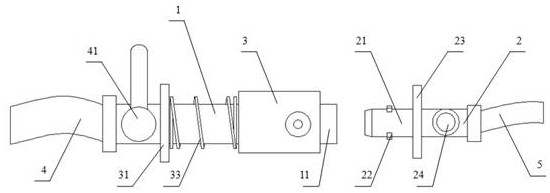

[0026] Please refer to figure 1 , a hydrogen filling device with a gas leak detection function, comprising a hydrogenation joint 1 and a gas receiving joint 2, the hydrogenation joint 1 includes a hydrogenation pipe 11 and a sealing sleeve 3, and the gas receiving joint 2 includes a hydrogen receiving pipe 21, The hydrogenation pipe 11 is arranged on the hydrogenation machine and is connected with the hydrogenation machine through the hydrogen delivery pipe 4, and the hydrogen receiving pipe 21 is arranged on the hydrogen energy vehicle, and communicates with the hydrogen storage tank of the hydrogen energy vehicle through the air guide pipe 5 , the hydrogenation connector 1 is used to airtightly connect with the gas receiving connector 2, so that the hydrogenation machine can refuel the hydrogen storage tank of the hydrogen energy vehicle.

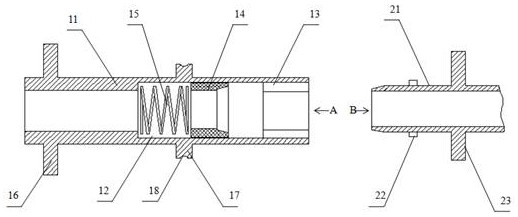

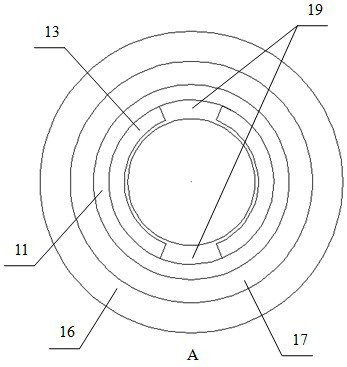

[0027] Specifically, please refer to Figure 1 to Figure 5 , the hydrogenation pipe 11 is provided with a holding tank 12 that is sunke...

Embodiment 2

[0035] Please refer to Figure 7 The difference between Embodiment 2 of the present invention and Embodiment 1 is that the concentration detection device 34 on the sealing sleeve 3 is replaced by an alarm whistle, and the alarm whistle is embedded in the pipe wall of the sealing sleeve 3. When When there is a hydrogenation machine for hydrogenation, if hydrogen gas leaks into the sealing sleeve 3 at the connection between the hydrogenation joint 1 and the gas receiving joint 2, the hydrogen in the sealing sleeve 3 will escape from the sealing sleeve 3 through the alarm whistle, and the alarm gas will be released at this time. The whistle will be beeping to sound an air leak alarm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com