Fully mechanized coal mining face transportation crossheading unit support carrying system

A technology of fully mechanized mining face and transportation along the trough, which is applied in underground transportation, transportation and packaging, earthwork drilling and mining, etc. It can solve the problems of bulky support, time-consuming and labor-intensive, and aggravated roof damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

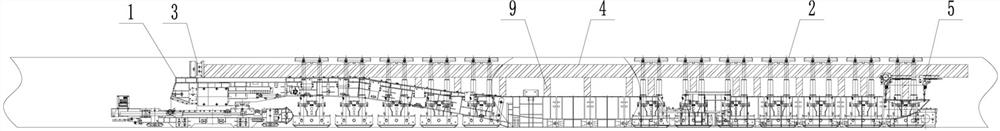

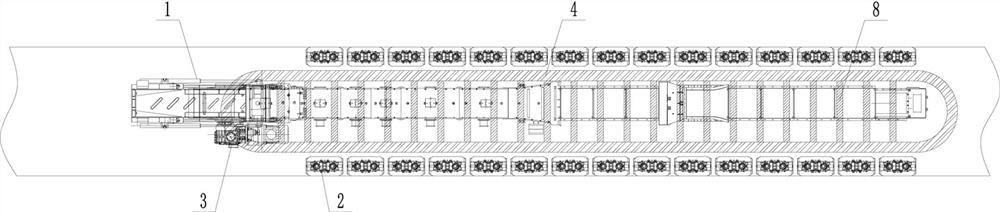

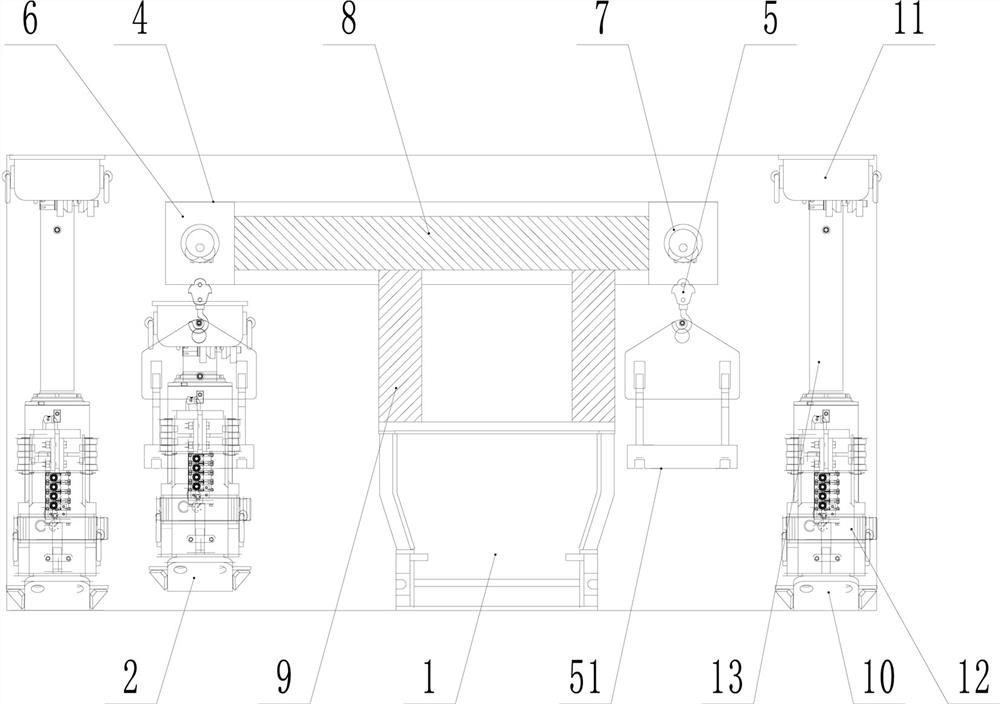

[0022] Such as Figure 1-5 As shown in the figure, a system for transporting and transporting unit supports in fully mechanized mining working faces, including a transfer machine 1, a ring lifting device, and a plurality of unit supports 2 arranged on both sides of the roadway, the unit supports 2 are used to support both sides of the roadway , the ring lifting device includes a bidirectional drive motor 3, a ring guide and a lifting trolley 5, and the ring guide is installed above the transfer machine 1, so that the space left above the transfer machine 1 is fully utilized, so that all The reloading machine 1 can advance together with the annular guide device; the hoisting trolley 5 is hoisted below the annular guide device, and the travel path of the lifting trolley 5 surrounds both sides of the reloading machine 2 and the rear, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com