Ammonia-soda-process soda ash production process optimization system based on material balance

A production process and material balance technology, applied in carbonate preparations and other directions, can solve the problems of affecting soda ash production capacity, long maintenance time, equipment blockage, etc., and achieve the effect of ensuring soda ash production capacity, reducing production costs, and shortening maintenance time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

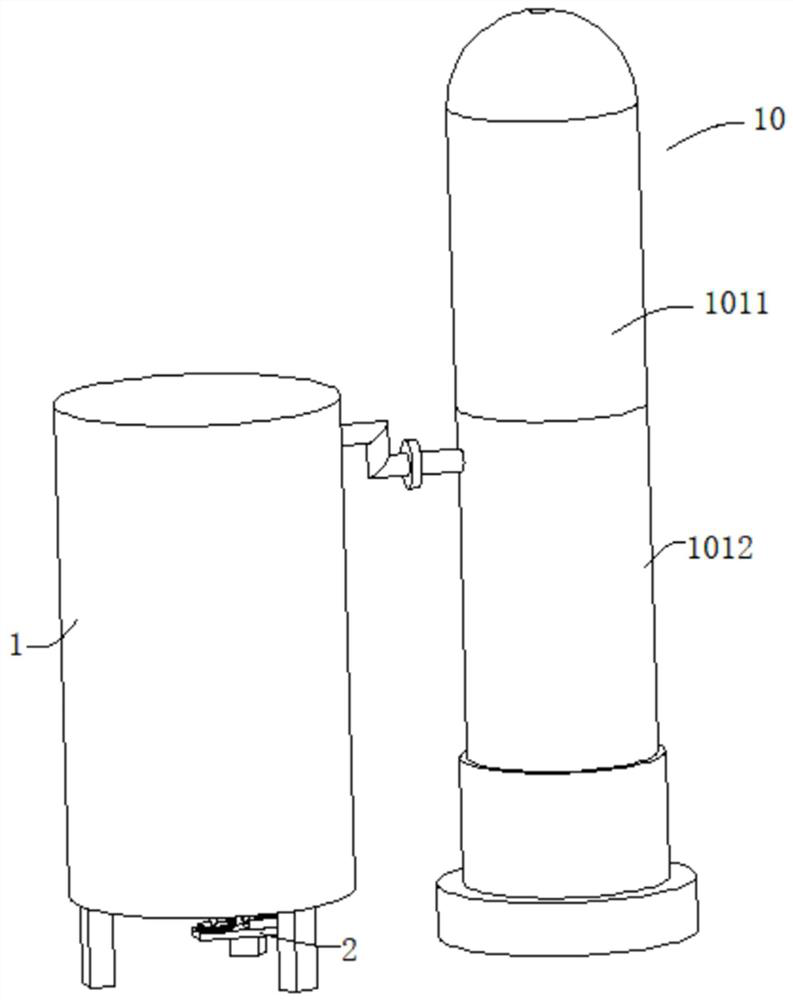

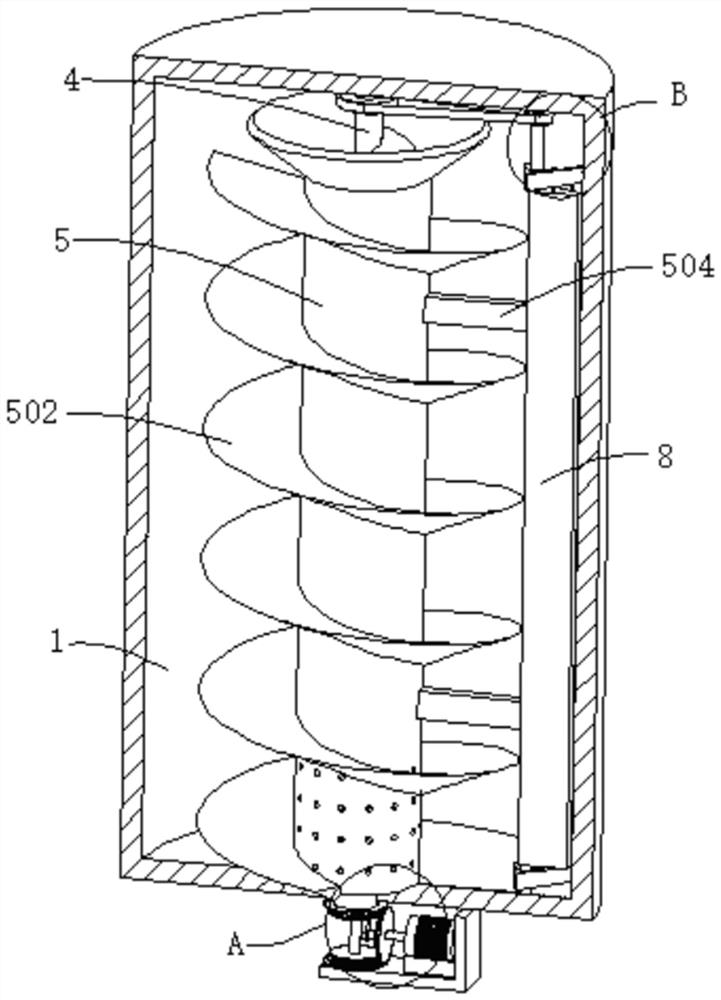

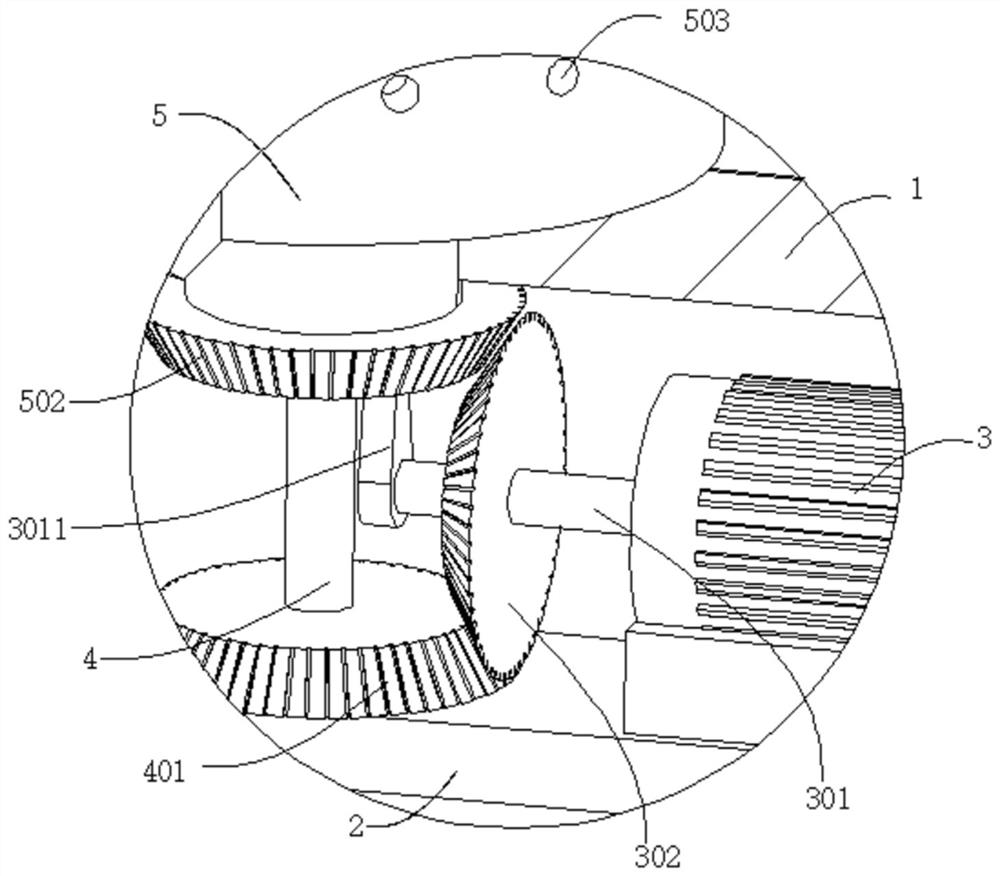

[0034] refer to figure 1 , figure 2 , image 3 and Figure 5 , a system for optimizing the soda ash production process based on material balance, comprising a pre-ash tank 1 and an ammonia distillation tower 10, the pre-ash tank 1 and the ammonia distillation tower 10 are connected to each other through connecting pipes, and the bottom of the pre-ash tank 1 is connected with Support base 2, the outer wall of support base 2 is connected with motor 3, the output end of motor 3 is connected with rotating shaft 301, and the end of rotating shaft 301 away from motor 3 is connected with first bevel gear 302, the top inner wall and the bottom inner wall of pre-ash bucket 1 The rotating rod 4 and the rotating tube 5 are respectively connected in rotation through the first bearing and the second bearing. The rotating rod 4 is placed in the rotating tube 5. The second bevel gear 401 and the third bevel gear 501, the outer wall of the rotating rod 4 is connected with the first helica...

Embodiment 2

[0039] refer to figure 1 , figure 2 , image 3 , Figure 5 and Figure 6 , a system for optimizing the soda ash production process based on material balance, comprising a pre-ash tank 1 and an ammonia distillation tower 10, the pre-ash tank 1 and the ammonia distillation tower 10 are connected to each other through connecting pipes, and the bottom of the pre-ash tank 1 is connected with Support base 2, the outer wall of support base 2 is connected with motor 3, the output end of motor 3 is connected with rotating shaft 301, and the end of rotating shaft 301 away from motor 3 is connected with first bevel gear 302, the top inner wall and the bottom inner wall of pre-ash bucket 1 The rotating rod 4 and the rotating tube 5 are respectively connected in rotation through the first bearing and the second bearing. The rotating rod 4 is placed in the rotating tube 5. The second bevel gear 401 and the third bevel gear 501, the outer wall of the rotating rod 4 is connected with the...

Embodiment 3

[0046] refer to Figure 4 , Figure 5 and Figure 7 , an ammonia-soda method soda ash production process optimization system based on material balance, which is basically the same as Embodiment 2, and furthermore, a connecting rod 504 is connected to the outer wall of the rotating tube 5, and a scraper is connected to the end of the connecting rod 504 away from the rotating tube 5. Plate 8, scraper 8 and the inwall of pre-ash bucket 1 are offset.

[0047] The upper and lower outer walls of the scraper 8 are connected with a swing plate 801 through pin shaft rotation, a knocking plate 802 is connected between the two swinging plates 801, and a second elastic element 805 is connected between the knocking plate 802 and the scraper 8 , and the knock plate 802 is offset with the inwall of the pre-ash bucket 1, the scraper 8 is rotated and connected with a movable rod 803, and the outer wall of the movable rod 803 is connected with a second cam 804, and the second cam 804 is offse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com