A method for eliminating paper edge laser interference and paper roll instability

A kind of laser paper and laser technology, which is applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems of the influence of tension stability of the overall printing unit, affect the final pass rate of products, and the low precision of overprinting B system. Overprinting consumption, avoiding overprinting waste, and eliminating the effect of laser interference on the edge of the paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0031] It should be noted that the structures, proportions, sizes, etc. shown in this specification are only used to cooperate with the contents disclosed in the specification, so as to be understood and read by those who are familiar with this technology, and are not used to limit the conditions that the present invention can be implemented. , any modification of the structure, the change of the proportional relationship or the adjustment of the size, without affecting the effect that the present invention can produce and the purpose that can be achieved, should still fall within the scope that the technical content disclosed in the present invention can cover .

[0032] At the same time, the terms such as "up", "down", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and clarity, and are not used to limit this specification. The implementable scope of the invention, and the change or adjustment of the relative relat...

Embodiment 1

[0034] The invention discloses a method for eliminating paper edge laser interference and paper roll instability, comprising the following steps:

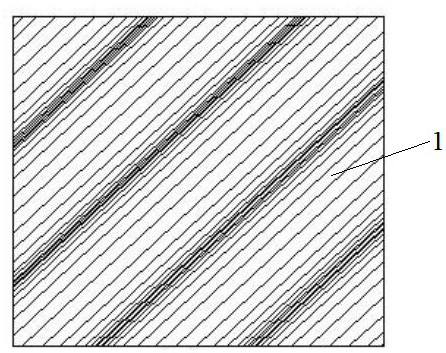

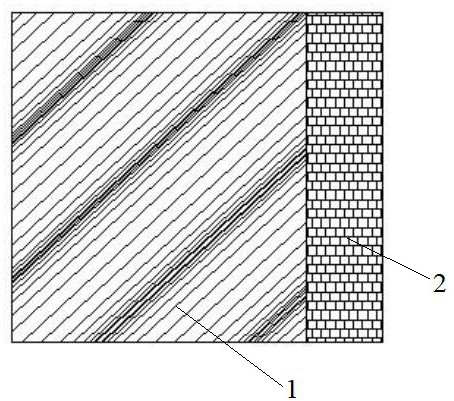

[0035] Step 1: Pre-print the edge of the substrate laser paper to obtain pre-printed color bars;

[0036] Step 2: Overprint the white bar on the pre-printed color bar, the white bar is the same shape and size as the pre-printed color bar;

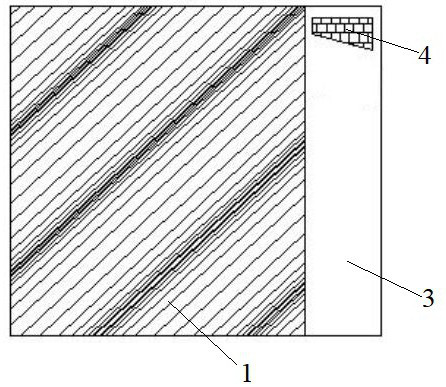

[0037] Step 3: Make a void cursor on the white bar, and the void cursor is used as a white cursor;

[0038] Step 4: Overprint the remaining cursor of the printed product on the white bar;

[0039] Step 5: Set the overprint tracking in the automatic overprint system;

[0040] Step 6: Overprint compensation to complete accurate overprinting.

Embodiment 2

[0042] Preferably, in the step 1, the pretreatment of color printing on the edge of the laser paper of the substrate is to use a printing unit to perform non-overprint coating on the edge of the laser paper, the thickness of the coating ink layer is 70 lines of 55 μm, and the coating width is 13 ~15mm.

[0043] Preferably, in the step 1, the pre-printed color bars are printed silver or gray ink, and the pre-printed color bars are made by a gravure silver ink or gray ink printing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com