Solar panel surface automatic film pasting forming equipment

A technology for solar panels and molding equipment, applied in electrical components, climate sustainability, circuits, etc., can solve problems such as low work efficiency, low film quality, and protective film folds, so as to improve practicability and reliability, and improve practicality. stability, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

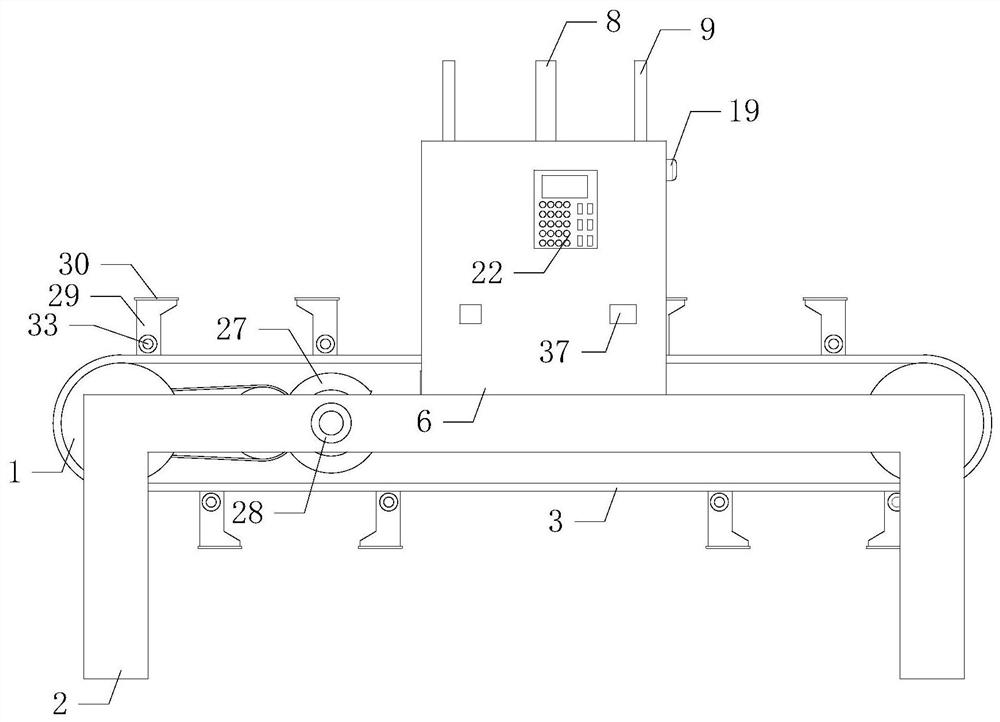

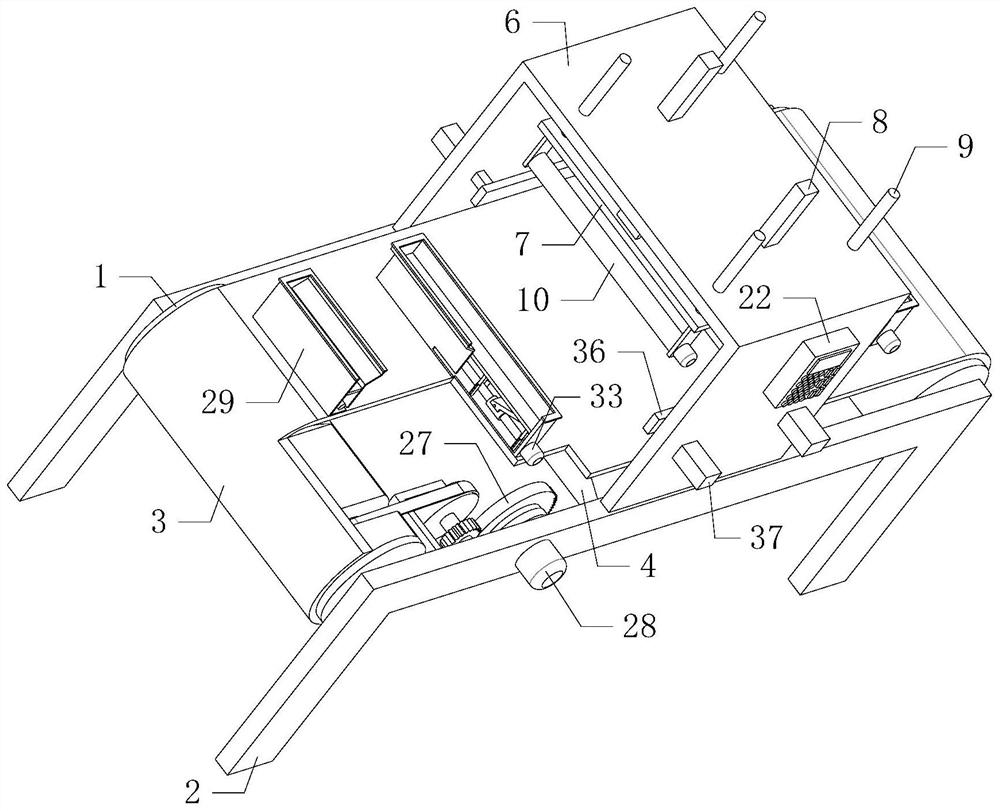

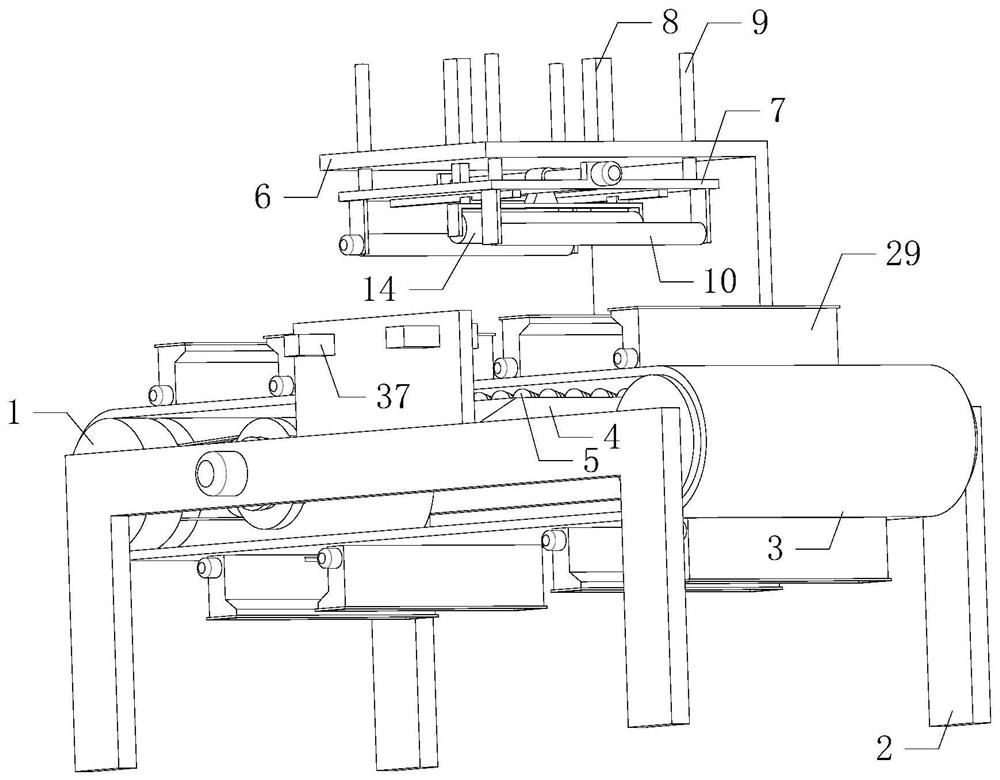

[0021] Such as Figure 1 to Figure 6 As shown, a kind of solar panel surface automatic film forming equipment of the present invention, when it is working, pulls the coil protruding end of the winding state on the right side belt roller 10 to wind on the left side belt roller 10, and the central control box 22 Control and open the first motor 12, the first motor 12 drives the left side belt roll 10 to rotate, the left side belt roll 10 pulls the belt roll on the right side belt roll 10 through the belt coil wound on it and stretches out, and the tape sticking on the belt roll The square protective film stretches out and moves between the two sets of belt rollers 10. At th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com