Laser trimming device and method for superhard abrasive forming grinding wheel

A shaped grinding wheel and laser dressing technology, which is applied in the direction of abrasive surface adjustment devices, laser welding equipment, grinding/polishing equipment, etc., can solve the problems of low efficiency, achieve high dressing efficiency, low grinding wheel runout and roundness errors, and improve The effect of sharpening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

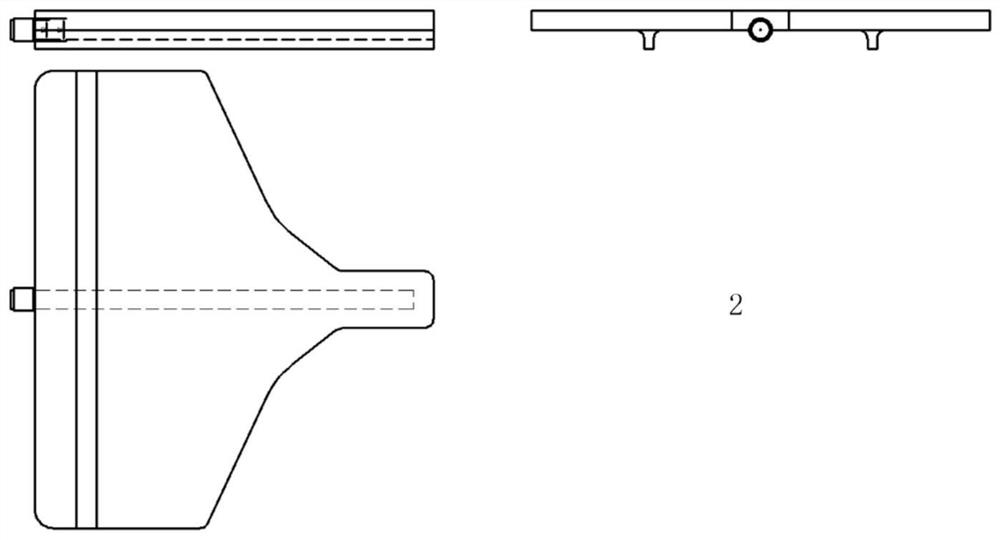

[0076] like Figure 1 to Figure 13 As shown, a laser dressing device for forming a superabrasive grinding wheel described in this embodiment includes a reflective lens seat 1, a horizontal displacement adjustment table 2, a vertical displacement adjustment frame 3, a fixed support 4, a reflective lens clamp 5, and a fixed angle Turn knob 6 and displacement screw 7. like Figures 2 to 5 As shown, the bottom end of the reflective lens holder 1 is connected to the slide rail of the horizontal displacement adjustment table 2 with a y-direction displacement screw; The slide rail of the adjustment frame 3; the vertical displacement adjustment frame is connected to the fixed support 4, and the fixed support 4 is fixed to the laser trimming workbench by hexagon socket head screws. The device is equipped with reflective lens clamp, reflective lens seat, horizontal displacement adjustment table, vertical displacement adjustment frame and fixed support in sequence along the laser beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com