Quantitative feeding device for chemical production

A feeding device, a technology for chemical production, applied in feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of economic loss, affecting product quality, insufficient reaction, etc., to prevent waste and improve work economy. Benefit, avoid underreacting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the embodiments of the present invention will be clearly and completely described below. The embodiments of the present invention and all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

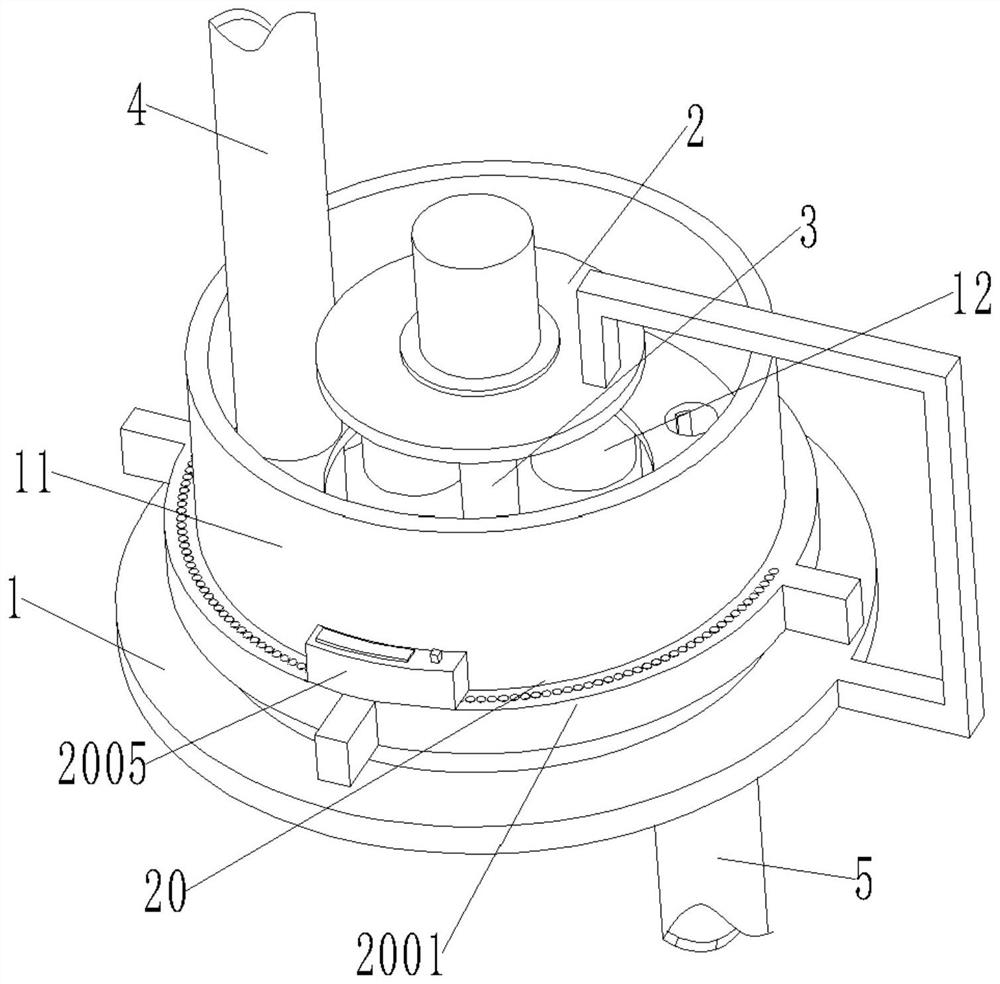

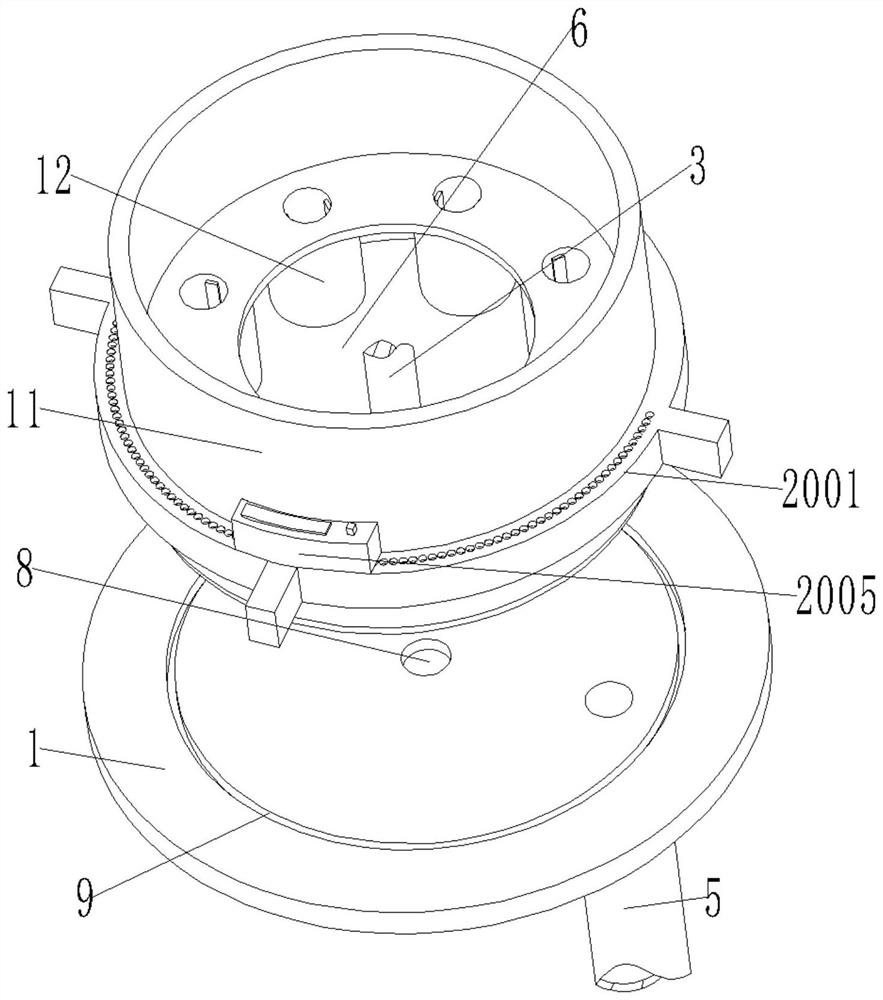

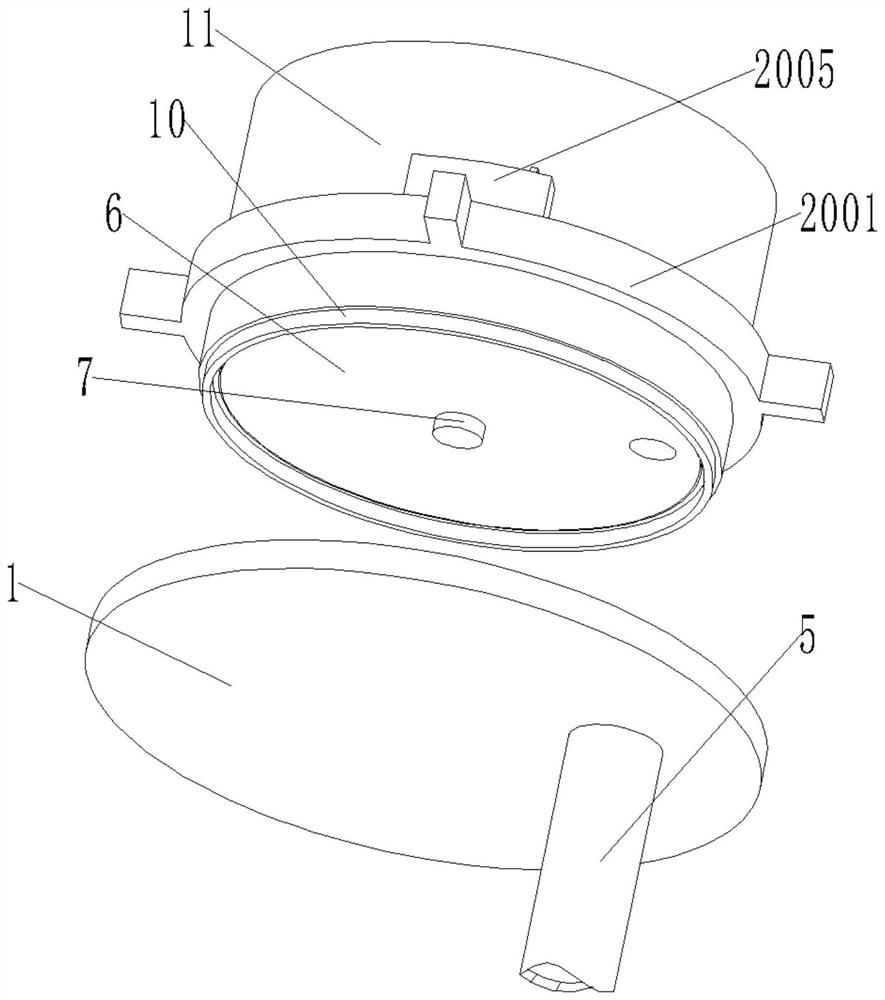

[0025] see figure see Figure 1 to Figure 7 , the present invention provides a technical solution: a quantitative feeding device for chemical production, the present invention includes a support fixed plate 1, a connection fixed plate 2, a rotating shaft 3, a material delivery pipe 4, a feed pipe 5 and a material holding cylinder 12 , Sheng material barrel 12, quantitative control mechanism 20;

[0026] The supporting fixed disk 1 and the connecting fixed disk 2 are fixedly connected by connecting rods, and the connecting fixed disk 2 is provided with a rotating shaft 3, the other end of the rotating shaft 3 is connected with a motor, and the bottom su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com