Plasma component rapid separation system

A separation system and rapid technology, applied in the field of plasma component rapid separation system, can solve the problems of uneven mixing of plasma and acid, low efficiency, long separation time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the accompanying drawings.

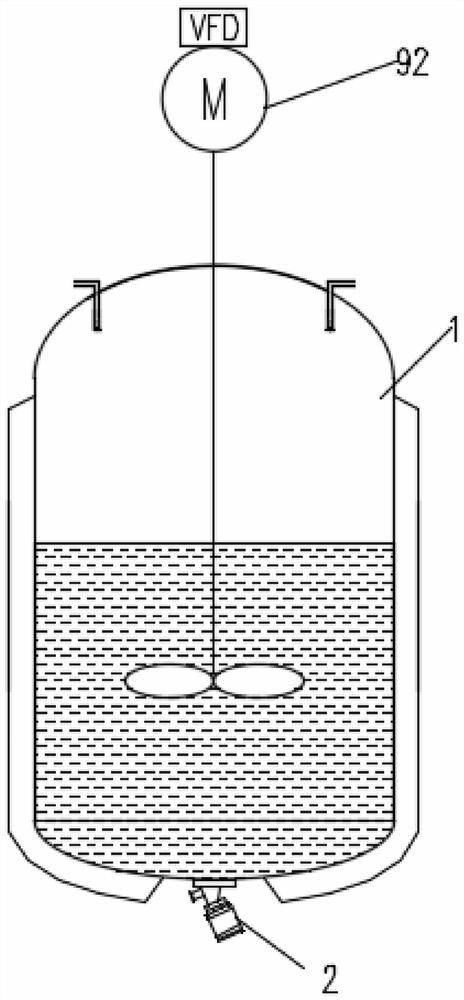

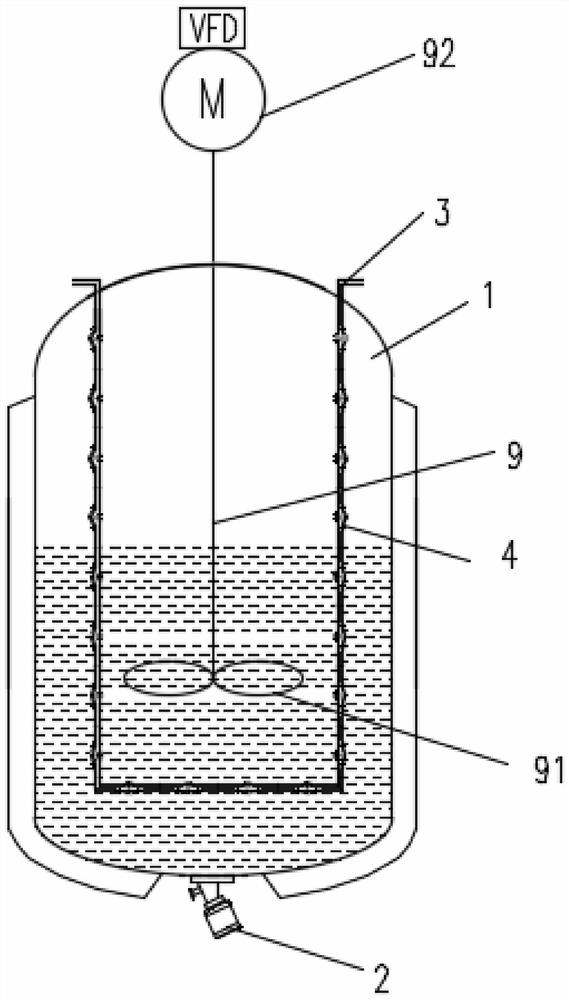

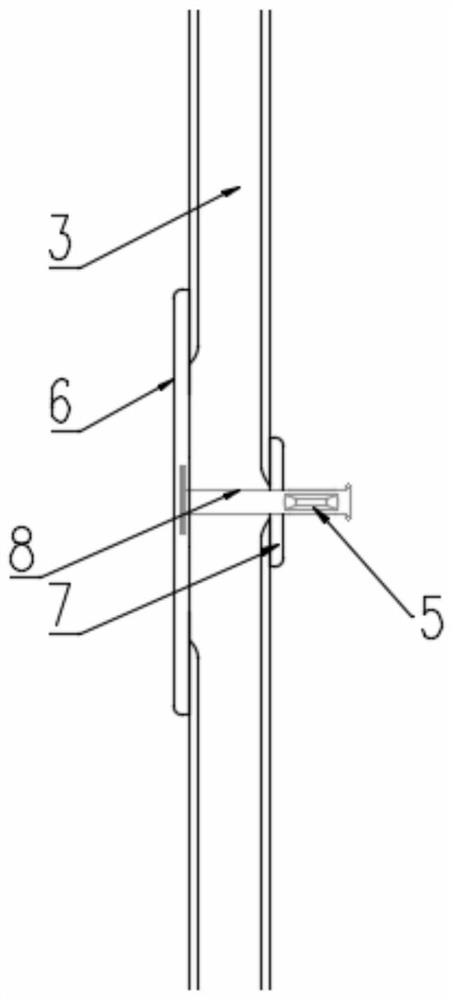

[0027] In the case of implementation, if Figure 1-7 As shown, a plasma component rapid separation system includes a reactant tank 1, and a manual valve 2 is provided at the lower end of the reaction tank 1, and a stirring mechanism is provided in the reaction tank 1, which is provided with a liquid in the reaction tank 1. The pipe 3 is provided in the reaction tank 1, and the two openings of the upper end of the plurality of liquid pipes 3 extends through the reaction tank 1 outward, and the liquid pipe 3 A recess valve 4 is provided, and a groove 5 that allows liquid to pass through.

[0028] Thus, when the plasma component is separated, plasma is added to the reaction tank, and plasma inlet is provided on the reaction tank, and then the acid solution is added to the reaction tank by the opening of the liquid pipeline, and there is a reducing valve, which can be provided. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com