Packaging method for reducing poor insulation of soft package lithium battery

A soft-pack lithium battery and packaging method technology, which is applied in the field of lithium batteries, can solve the problems of affecting the safety and electrical performance of soft-pack batteries, damage to the PP layer of aluminum-plastic film, and failure to discharge in time, so as to avoid the problem of lithium analysis, The effect of reducing the size of the air bag and saving the amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this embodiment, the specific steps of the encapsulation method with the reserved air guide port for the pouch battery are as follows:

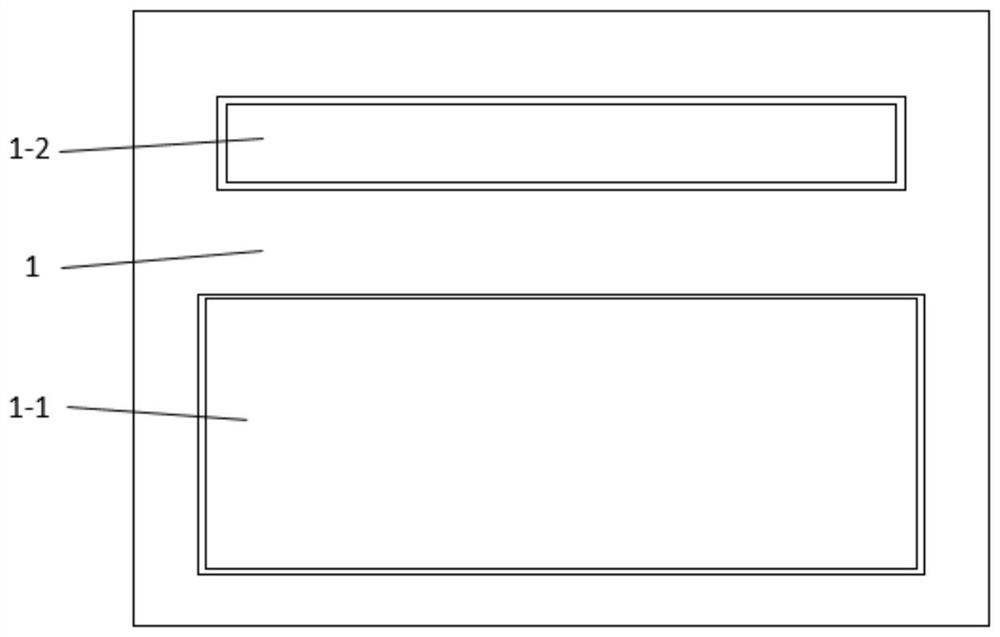

[0040] S1. Complete the punching of the aluminum-plastic film 1 with a thickness of 152um on the punching machine to form a cell pit 1-1 and an air bag pit 1-2, both of which are 4mm deep, such as figure 2 shown;

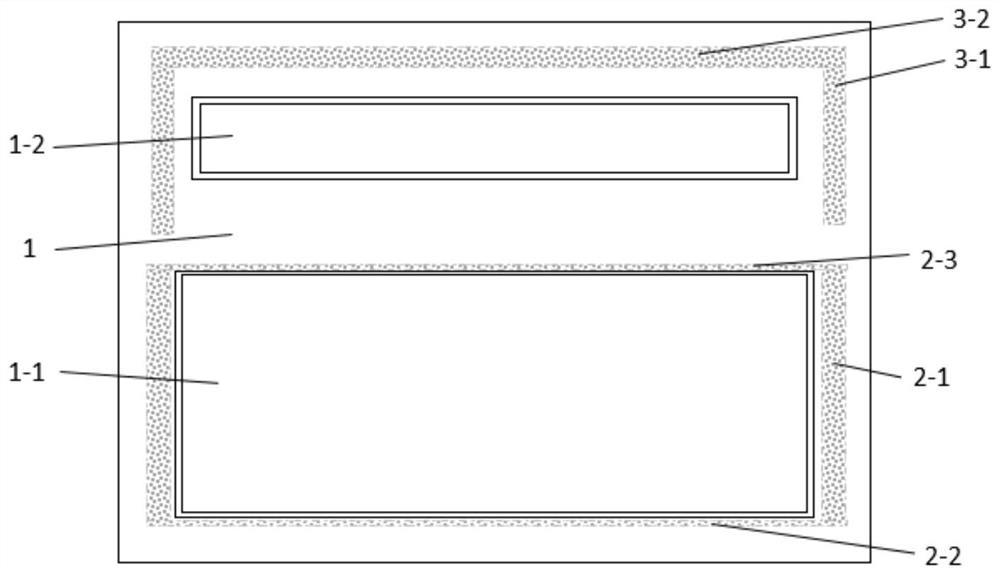

[0041] S2, heat-resistant coating coating, such as image 3 Shown: a. On the outside of cell pit 1-1, polyacrylate polymer coating 2-1 is sprayed on the PP layer along the edge of the top seal, with a thickness of 3um and a width of 10mm; b. On the outside of cell pit 1-1, along the side The PP layer on the edge of the seal area and the second seal area is sprayed with polyacrylate polymer materials to form heat-resistant coating 2-2, heat-resistant coating 2-3, thickness 3um, width 2mm; c, air bag pit 1-2 On the outside, spray polyacrylate polymer material along the edge of the top seal area to form a heat-resistant c...

Embodiment 2

[0048]In this embodiment, the specific steps of the encapsulation method with the reserved air guide port for the pouch battery are as follows:

[0049] S1. Complete the punching of the aluminum-plastic film 1 with a thickness of 152um on the punching machine to form a cell pit 1-1 and an air bag pit 1-2, both of which are 4mm deep, such as figure 2 shown;

[0050] S2, heat-resistant coating coating, such as Figure 6 Shown: a, the outside of the cell pit body, spray polyacrylate polymer material along the edge of the top seal to form a heat-resistant coating 2-1, with a thickness of 3um and a width of 10mm; b, the outside of the cell pit body, along the side The PP layer of the seal area and the edge of the second seal area is sprayed with polyacrylate polymer materials to form heat-resistant coatings 2-2, 2-3, with a thickness of 3um and a width of 2mm. And carry out UV cross-linking and curing treatment on the sprayed polymer coating to form a heat-resistant curing layer...

Embodiment 3

[0057] In this embodiment, the specific steps of the encapsulation method with the reserved air guide port for the pouch battery are as follows:

[0058] S1. Complete the punching of the aluminum-plastic film 1 with a thickness of 152um on the punching machine to form a cell pit 1-1 and an air bag pit 1-2, both of which are 4mm deep, such as figure 2 shown;

[0059] S2, heat-resistant coating coating, such as Figure 7 Shown: On the outside of the cell pit 1-1, spray polyacrylate polymer material along the edge of the top seal area to form a coating 2-1 with a thickness of 3um and a width of 10mm; Combined curing treatment to form a heat-resistant cured layer;

[0060] S3. Assemble the welded battery cells into the pit, and perform top sealing along the outer edge of the coating according to the top sealing process conditions of 185°C pressure 0.3Mpa and time 1.8s to form a top seal 5-1, according to 180°C pressure 0.3Mpa time 1.2 s Side sealing process conditions for side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com