A hot plate device for plasma dry degumming and its application method

A dry degumming and plasma technology, which is used in the manufacture of electrical components, circuits, semiconductor/solid-state devices, etc., to achieve the effect of increasing conduction efficiency, high dry degumming efficiency and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

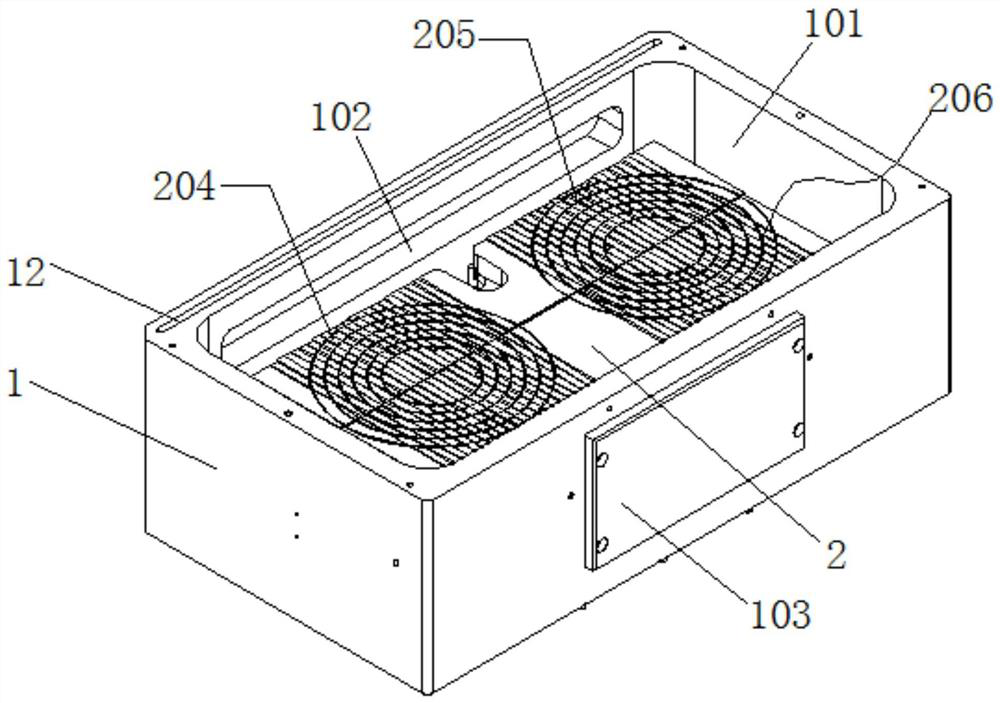

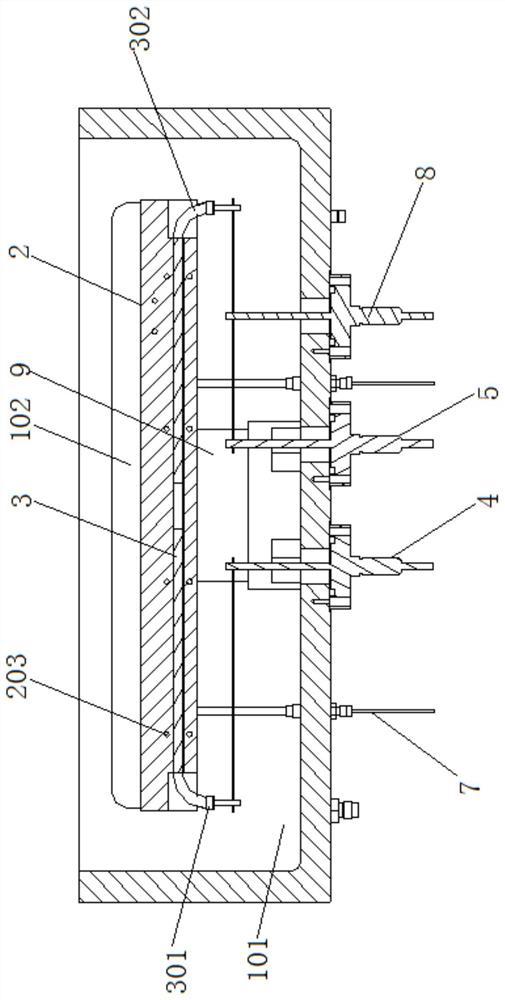

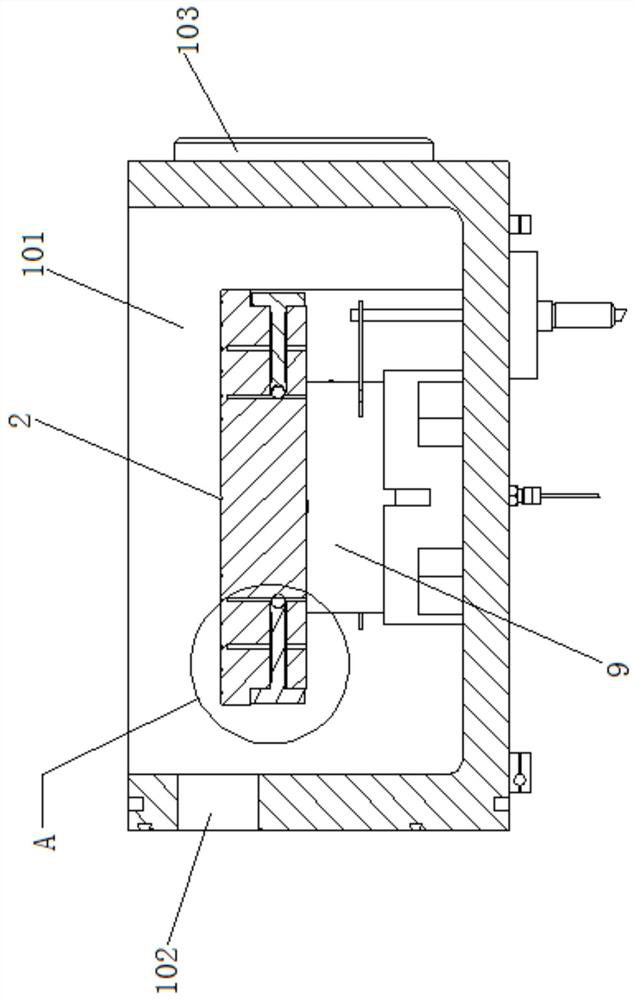

[0044] The present embodiment 1 discloses a hot plate device for degumming by plasma dry method. figure 1 , one of its main bodies includes a process cavity 1 , the process cavity 1 is in the shape of a rectangular parallelepiped as a whole, and a heating groove 101 is opened on the upper surface of the process cavity 1 . At the same time, a wafer extraction port 102 is also opened on the rear side of the process chamber 1, and a brand-name plate 103 is provided on the front side of the process chamber 1; The wafer is taken out, and the setting of the name plate 103 can surface the relevant information of the whole device.

[0045] Reference attached figure 1 , a heating plate body 2 is fixedly arranged in the heating groove 101. When specifically set, the heating plate body 2 is made of aluminum whose surface has been anodized, and the heating plate body 2 made of anodized aluminum can The heat is efficiently transferred to the surface of the product, and the uniformity of ...

Embodiment 2

[0051] This embodiment 2 discloses a hot plate device based on the improved dual-station plasma dry method based on the embodiment 1. It will be described in detail below with reference to the accompanying drawings.

[0052] This embodiment 2 discloses a hot plate device for double-station plasma dry degumming. figure 1 , one of its main bodies includes a process cavity 1 , the process cavity 1 is in the shape of a rectangular parallelepiped as a whole, and a heating groove 101 is opened on the upper surface of the process cavity 1 . At the same time, a wafer extraction port 102 is also opened on the rear side of the process chamber 1, and a brand-name plate 103 is provided on the front side of the process chamber 1; The wafer is taken out, and the setting of the name plate 103 can surface the relevant information of the whole device.

[0053] Reference attached figure 1 , a heating plate body 2 is fixedly arranged in the heating groove 101. When specifically set, the heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com