Omnibearing greasing system for shaft sleeves

An all-round, oil injection technology, applied in the direction of bearing components, shafts and bearings, engine lubrication, etc., can solve problems such as affecting product quality, incomplete oil injection, equipment damage, etc., to save manpower and facilitate operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

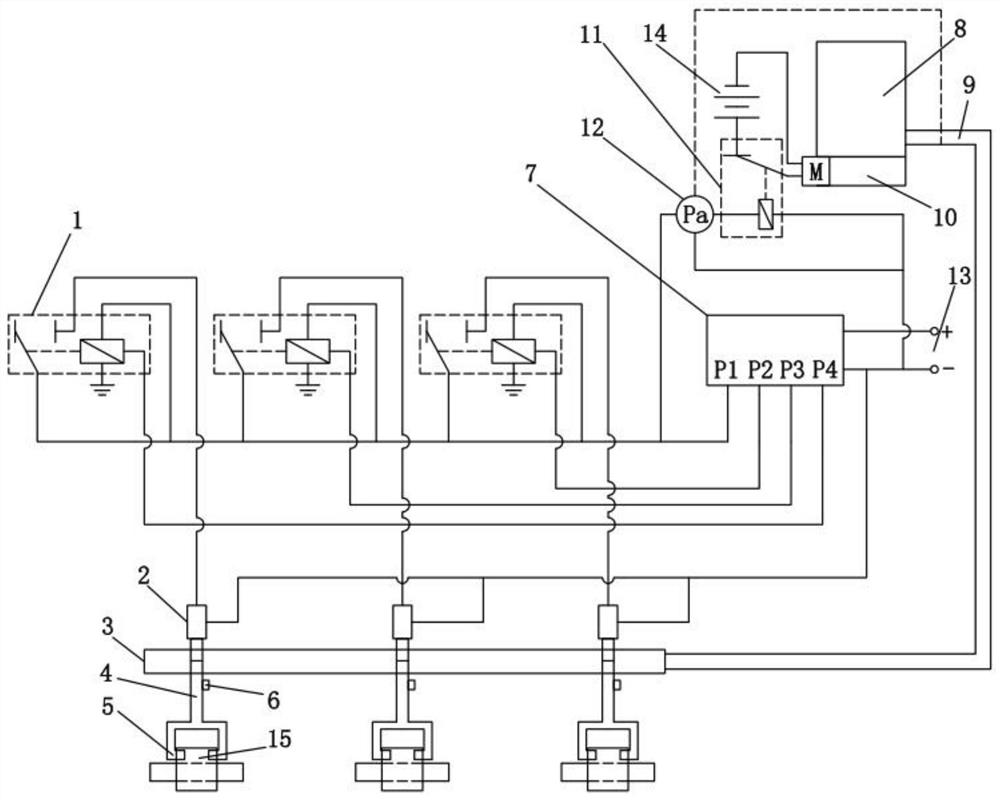

[0022] Such as figure 1 As shown, an all-round oiling system for shaft sleeves, including: butter bucket 8, distributing valve 2, oil separator 3, controller and remote controller, the controller includes a control circuit and a remote control transceiver matching the controller Unit 7, the butter barrel 8 is connected to the oil separator 3 through the main oil pipe 9, and the oil separator 3 includes a number of branch oil pipes 4, and the branch oil pipes 4 are connected to the main oil pipe 9 through the oil separator 3; the distribution valve 2 is located in the branch On the oil pipe 4, the remote control transceiver unit 7 is used to receive the control signal from the remote controller, and the control circuit is used to control the opening and closing of the distribution valve 2 according to the control signal.

[0023] The remote control transceiver unit 7 is externally connected to the positive and negative poles of the first power supply 13. The remote control tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com