Mechanical tilt cylinder for concrete mechanical pumping

A concrete machinery and pumping technology, which is applied in the field of mechanical swing cylinders, can solve problems such as swing instability of the swing cylinder, increased friction, and increased wear of the ball heads at both ends of the swing cylinder, so as to increase convenience and facilitate fixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

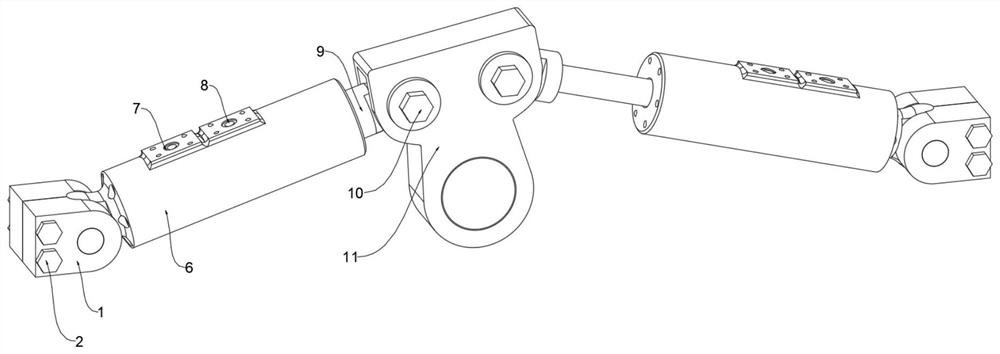

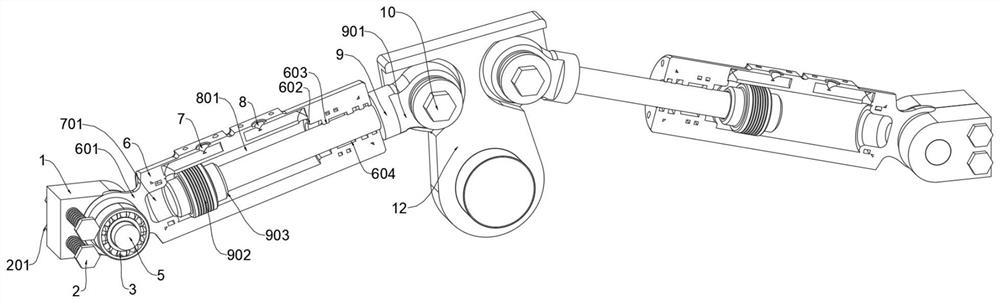

[0029] Append figure 1 Adherent Figure 6 Down:

[0030] The present invention provides a concrete mechanical pumping mechanical ring tank comprising a fixed mounting seat 1; a fixed bolt 2 is provided outside the fixed mounting seat 1, and the inner side of the connection hole 102 of the mounting seat 1 is provided with bearing 3, fixed The connection hole 102 of the mount 1 is connected to the connecting post 5, and the intermediate portion of the connecting post 5 is provided with a connecting ball head 4, and a bearing 3 is provided on both sides of the connecting ball head 4, and the connecting ball head 4 is rotated to be connected to the bevel hydraulic pressure. In the lattrach connecting head 601 at the bottom of the cylinder 6, in use, when the beeled cylinder hydraulic cylinder 6 is swung, the connecting ball head 4 in the beacon connection head 601 drives the connection post 5 to rotate, and the bearing 3 can reduce the connection column. 5 and the friction between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com