Anti-blocking reducing bidirectional cement mixing pile

A cement mixing pile and anti-blocking technology, which is applied in the direction of sheet pile walls, buildings, sealing/isolation, etc., can solve the problems affecting the construction process, cement transportation, and easy blockage of drill pipes, so as to prevent blocking and stabilize the connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

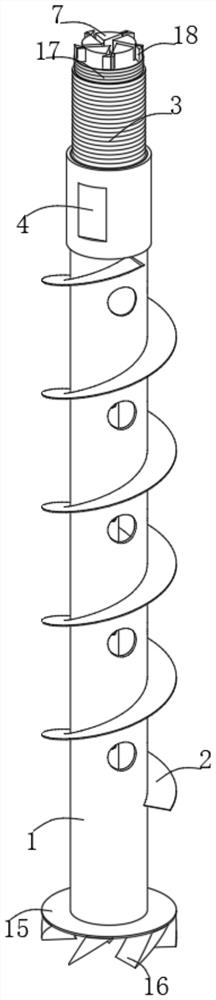

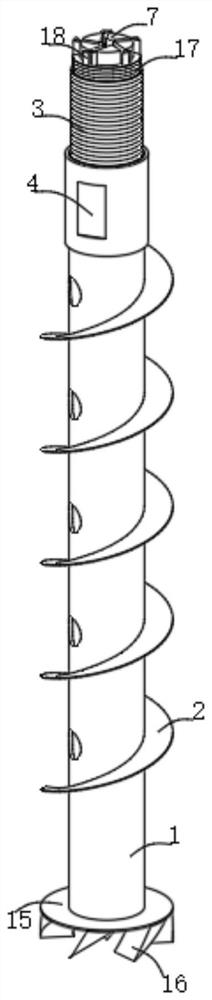

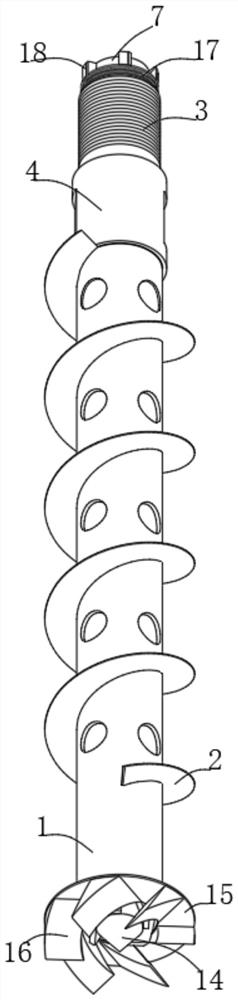

[0028] Embodiment one, with reference to Figure 1-9 : a kind of anti-clogging variable-diameter two-way cement mixing pile, comprising a drill pipe body 1, a threaded connecting pipe 3 and a threaded bottom pipe 13, the establishment of the drill pipe body 1 provides an installation foundation for setting other functional parts, and the threaded connection The establishment of the pipe 3 can effectively splice multiple drill pipe bodies 1, and at the same time enable the equipment to be firmly connected with the cement mixing pile device. The establishment of the threaded bottom pipe 13 facilitates the installation of other functional components of the equipment. The threaded connection pipe 3 A collar 4 is sleeved at the center of the outer surface. The setting of the collar 4 is convenient for fixing the position of the equipment, thereby facilitating the installation and disassembly of the equipment. The inside of the threaded connecting pipe 3 is fixedly connected with a f...

Embodiment 2

[0029] Embodiment two, refer to Figure 4-9: The drill pipe body 1 is a hollow cylindrical structure, and the top and bottom of the drill pipe body 1 are open structures. The establishment of this structure facilitates the installation and setting of other functional parts of the equipment. The outer surface of the drill pipe body 1 is along the vertical direction There are multiple groups of mixing ports at equal distances. The setting of the mixing ports enables the external mud to be effectively injected into the inside of the drill pipe body 1. There are two sets of mixing ports in each group. The outer surface of the drill pipe body 1 is provided with a first pusher. piece 2, the establishment of the first push piece 2 can effectively carry out the transportation of external mud, the inner surface wall of the drill pipe body 1 is provided with a second internal thread near the edge of the top end and the bottom end, and the establishment of the second internal thread is ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com