Method for preventing blast-furnace tuyere sleeve from sinking

A technology of tuyere cover and small tuyere cover, applied in the direction of tuyere, etc., can solve the problems such as the inability to fundamentally solve alkali metal hazards, the inability to eliminate hidden dangers in safety production, and the inability to fundamentally solve problems, so as to eliminate major safety hazards and increase The effect of molten iron production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

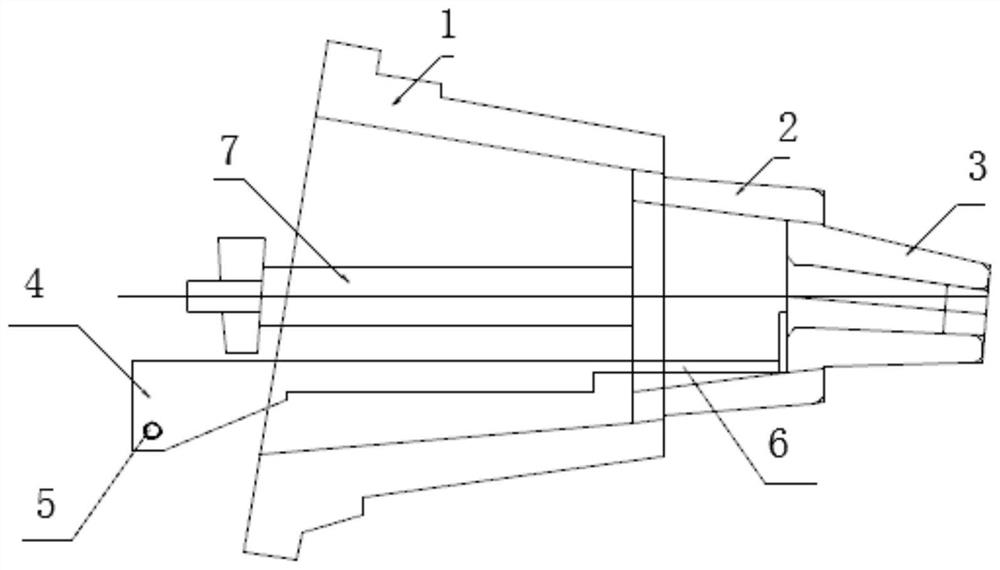

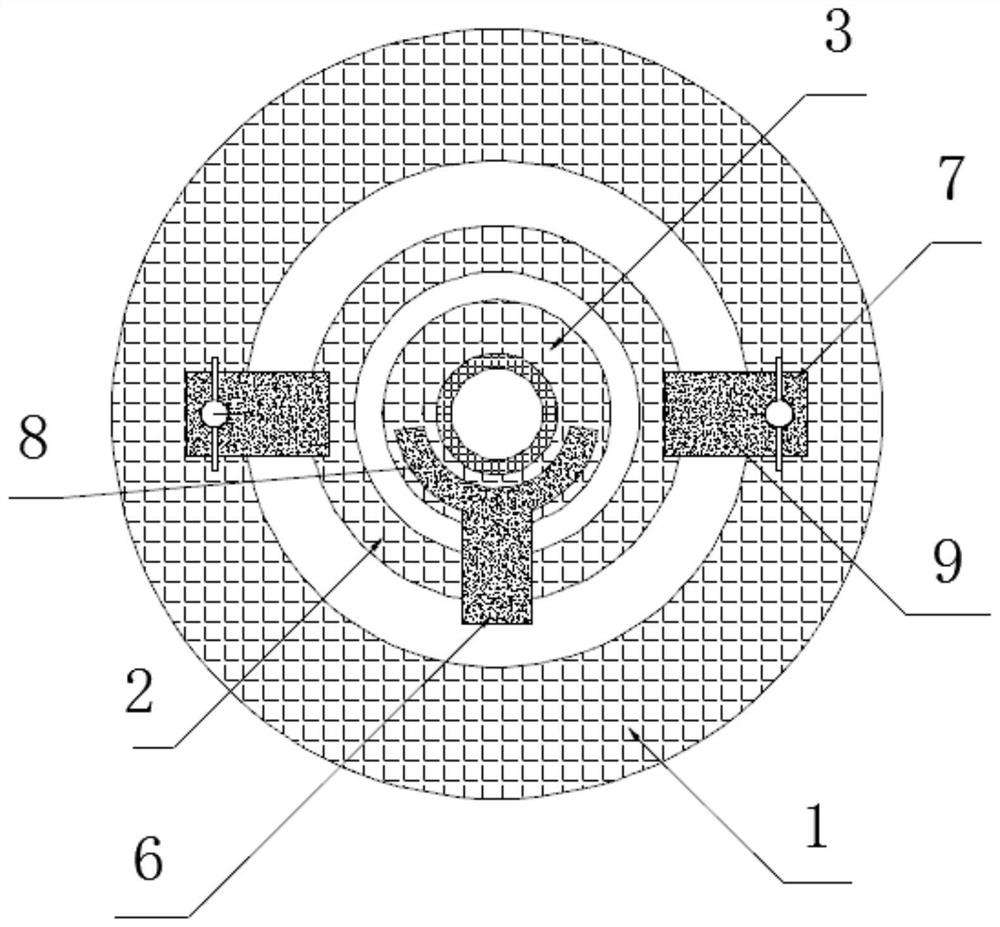

[0029] A method for preventing the tuyeres of a blast furnace from sinking, comprising the following processes:

[0030] ——Increase the alkali discharge rate of the iron mouth: control the quaternary alkalinity R of the slag 4 =(CaO+MgO) / (SiO 2 +Al 2 o 3 ) between 0.95 and 0.98 times; it can increase the dealkalization rate, so that the dealkalization (K2O+Na2O) rate of slag in the smelting process can reach 95.0 to 97.5%, which is 4.0 to 7.5% higher than the traditional slagging method, reaching an increase Large harmful elements are excluded from the iron mouth, reducing the enrichment of harmful elements in the furnace, reducing the erosion of refractory materials in the furnace and the peeling phenomenon caused by cracking of brick lining;

[0031] ——Increase the contact area of the matching surface between the small tuyere sleeve and the tuyere middle sleeve: that is, increase the mating contact length between the tuyere small sleeve and the tuyere middle sleeve, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com