Wood guide device for thicknesser machining

A guiding device and machining technology, which can be applied to planers, wood processing appliances, and processing machines for manufacturing flat surfaces, etc., can solve problems such as large flying dust, and achieve the effect of improving efficiency and processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments.

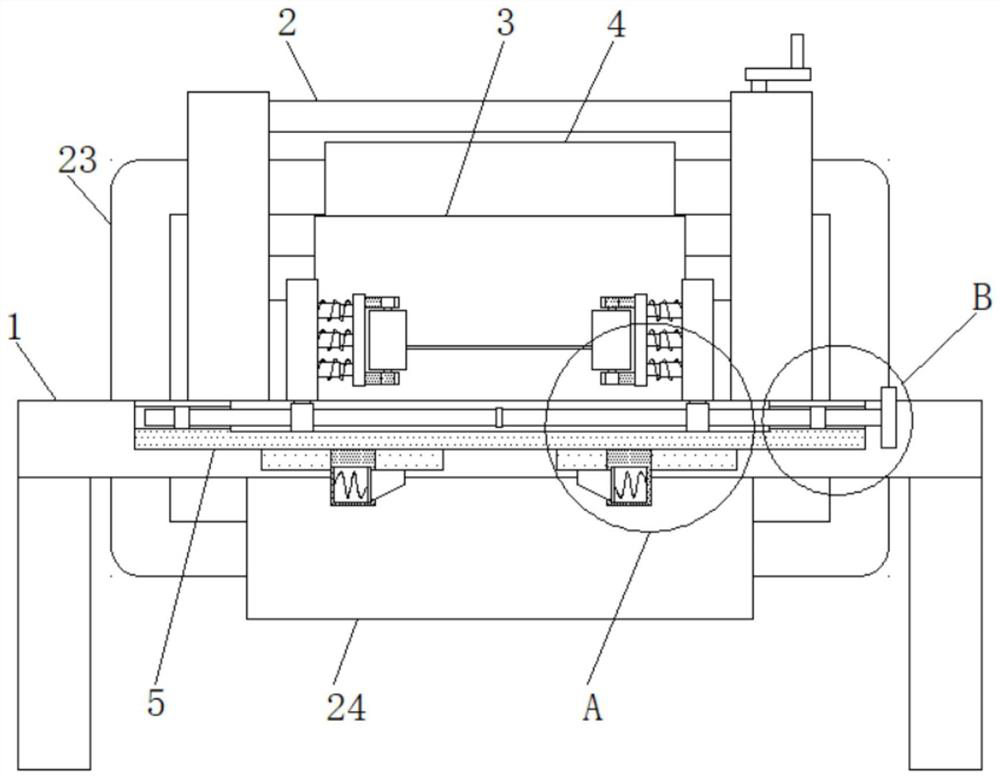

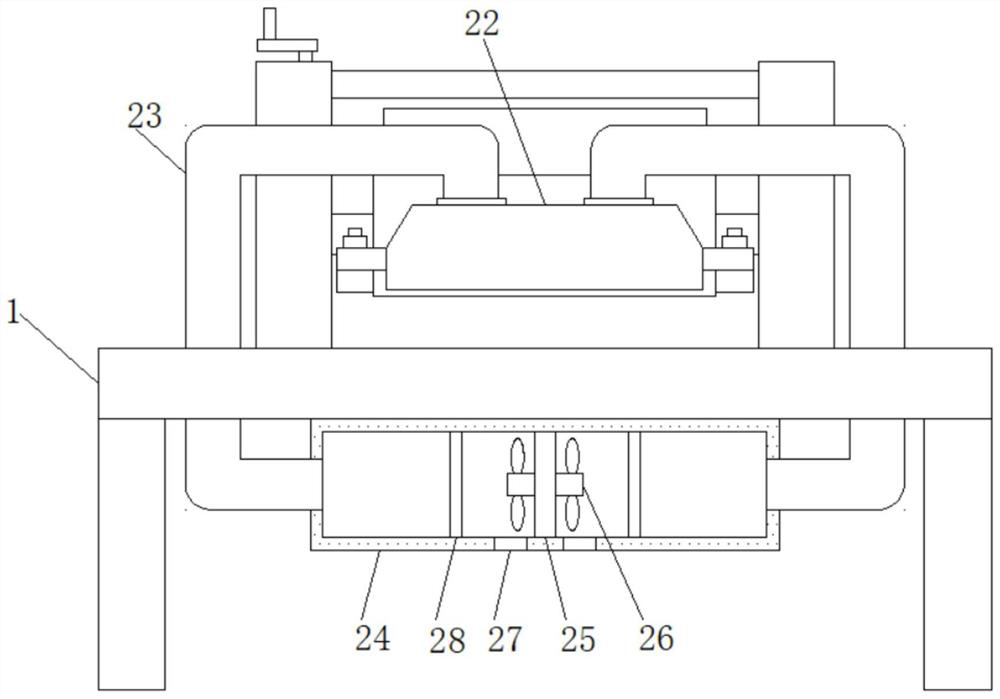

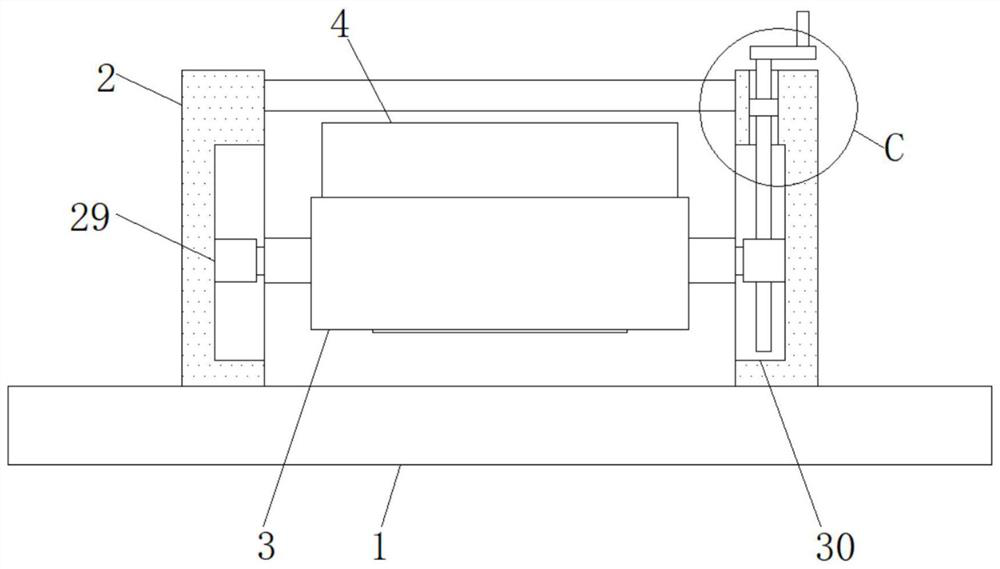

[0024] Refer Figure 1-6 A wood guiding device for pressing machine machining, including the base 1, the base 1 is fixed to the mounting frame 2, and the mounting frame 2 is attached to the mounting machine body 3, and the pressing machine body 3 is fixedly mounted. A lifting device is mounted between the power supply box 4, the pressing machine body 3 and the mounting frame 2, and the lifting device comprises two second sliding rods 29 on the outer wall of the embossed machine body 3, and the mounting frame 2 is symmetric There are two second chutes 30, the second slider 29, and the second chute 30, and the mounting bracket 2 is opened, and the second mounting hole 31 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com