A bimetal welding construction process method for surfacing prefabricated inner patch bimetal pipes

A construction technique and bimetal technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve problems such as inability to penetrate bimetal welds, reduce safety and environmental risks, improve pipeline life, and reduce waste of resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The specification of the bimetallic composite pipe is Φ914.4mm×68mm, the base material is ASTM A671CC65 carbon steel, the corrosion-resistant inner lining is UNS N06625 nickel-based alloy, and the thickness of the inner lining is 3 mm. The main operation steps are as follows:

[0043] (1) Double U-shaped groove processing:

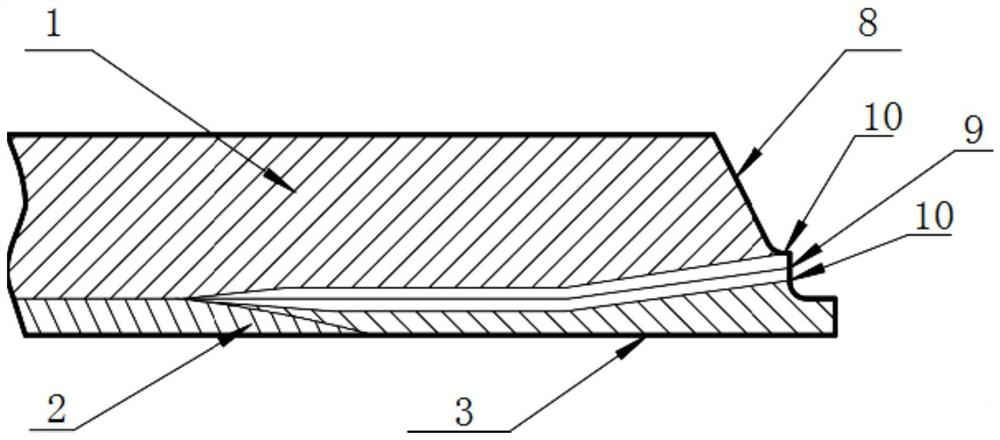

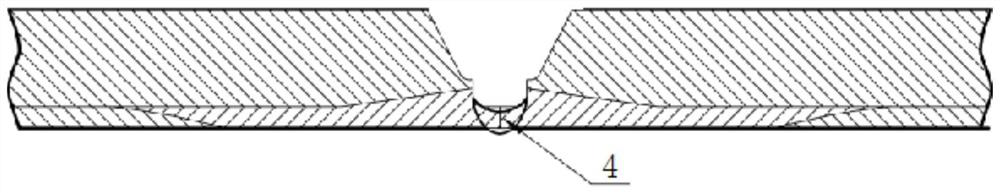

[0044] Double U-shaped groove processing such as ( figure 1 ), the blunt edge of the lower U-shaped groove is composed of surfacing corrosion-resistant alloy, and the groove surface is composed of surfacing welding dilution alloy; the upper U-shaped groove surface is composed of low-carbon steel base material, and its blunt edge is both the bevel face of the down bevel;

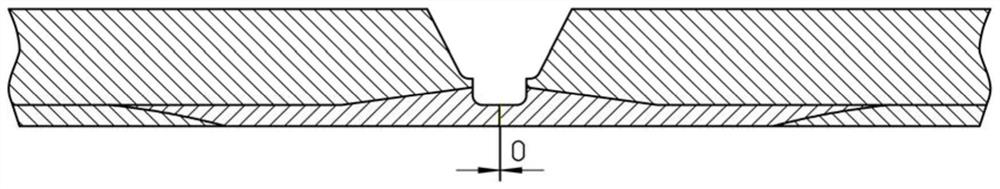

[0045] (2) Nozzle pair and back protection:

[0046] Before the nozzle assembly is cleaned, the impurity oil stains on the nozzle and the nearby area shall be removed, so that the bevel has a metallic luster, and the processing quality of the nozzle shall be checked to ensure th...

Embodiment 2

[0056] The specification of the bimetallic composite sea pipe is Φ219.1×14.3+3mm, the base material is PSL2X65SMLS according to API standard, and the lining is 316L stainless steel. The main operation steps of the process method are as follows:

[0057] (1) Double U-shaped groove processing:

[0058] Double U-shaped groove processing such as ( figure 1 ), the blunt edge of the lower U-shaped groove is composed of surfacing corrosion-resistant alloy, and the groove surface is composed of surfacing welding dilution alloy; the upper U-shaped groove surface is composed of low-carbon steel base material, and its blunt edge is both the bevel face of the down bevel;

[0059] (2) Nozzle pair and back protection:

[0060] Before the nozzle assembly is cleaned, the impurity oil stains on the nozzle and the surrounding area shall be removed, so that the bevel is exposed to metallic luster, and the processing quality of the nozzle shall be checked to ensure the integrity of the nozzle ...

Embodiment 3

[0070] The specification of the bimetallic composite sea pipe is Φ219.1×14.3+3mm, the base material is PSL2X65SMLS according to API standard, and the lining is 316L stainless steel. The main operation steps of the process method are as follows:

[0071] (1) Double U-shaped groove processing:

[0072] Double U-shaped groove processing such as ( figure 1 ), the blunt edge of the lower U-shaped groove is composed of surfacing corrosion-resistant alloy, and the groove surface is composed of surfacing welding dilution alloy; the upper U-shaped groove surface is composed of low-carbon steel base material, and its blunt edge is both the bevel face of the down bevel;

[0073] (2) Nozzle pair and back protection:

[0074] Before the nozzle assembly is cleaned, the impurity oil stains on the nozzle and the surrounding area shall be removed, so that the bevel is exposed to metallic luster, and the processing quality of the nozzle shall be checked to ensure the integrity of the nozzle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com