Full-automatic waste medical needle treatment device

A processing device, fully automatic technology, applied in the direction of needles, hypodermic injection devices, devices introduced into the body, etc., can solve the problems of inconvenient use, achieve the effects of convenient operation, low processing cost, and reduced risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0062] refer to Figure 9-10 , Regarding the sleeve 11, the sleeve 11 of the present invention is used to wrap the needle tip 12-1 of the needle.

[0063] Because PE and PVC plastic materials can be processed into pipe bodies with a diameter of less than 2mm and an inner diameter of less than 0.5mm. Therefore, the sleeve pipe of the present invention is made of PE and PVC materials. At the same time, PE and PVC materials have appropriate elasticity. The sleeve can be set as a tubular shape with an outer diameter of 2 mm and an inner diameter of 0.3 mm. After the needle tip with an outer diameter of 0.62 mm-0.9 mm is inserted into the sleeve, it can pass Elastic tension, tightly wrapped on the needle tip, and will not fall off, and will not burst the sleeve.

[0064] PE and PVC plastic materials are processed into a tube body with an outer diameter of 2mm and an inner diameter of 0.4mm, at least suitable for needles with a needle tip outer diameter of 0.5mm-1mm.

[0065] Of ...

example 2

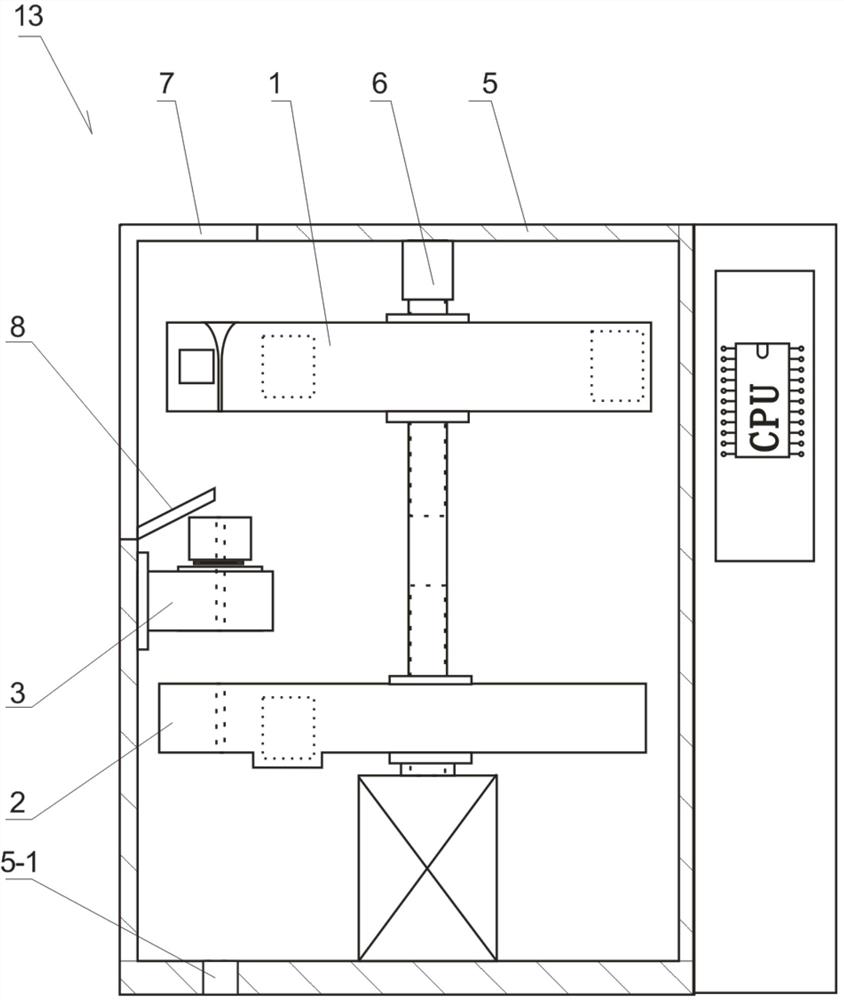

[0069] refer to Figure 13 ; The envelope device 13 is set in the upper part of the rear, the casing storehouse 4 is set in the lower part of the envelope device 13, and the casing roll is placed in the casing storehouse 4 . The collection bin 14 is arranged at the front of the device.

[0070] The casing 5 of the envelope device includes: a top casing, a bottom casing, a left casing, a right casing, a front casing, and a rear casing.

[0071] The silo wall of the casing silo is the same board as the bottom casing.

[0072] A third through hole 5-1 for the casing 11 to penetrate into the casing clamping hole 2-1 is provided on the casing wall (or the bottom casing) of the casing casing.

[0073] After the casing is used up, the casing must be installed into the casing warehouse, and the casing should be inserted into the envelope device for use.

[0074] The bin mouth of the waste needle collection bin is set near the window 7; a drawer 14-1 for collecting waste needles is ...

example 3

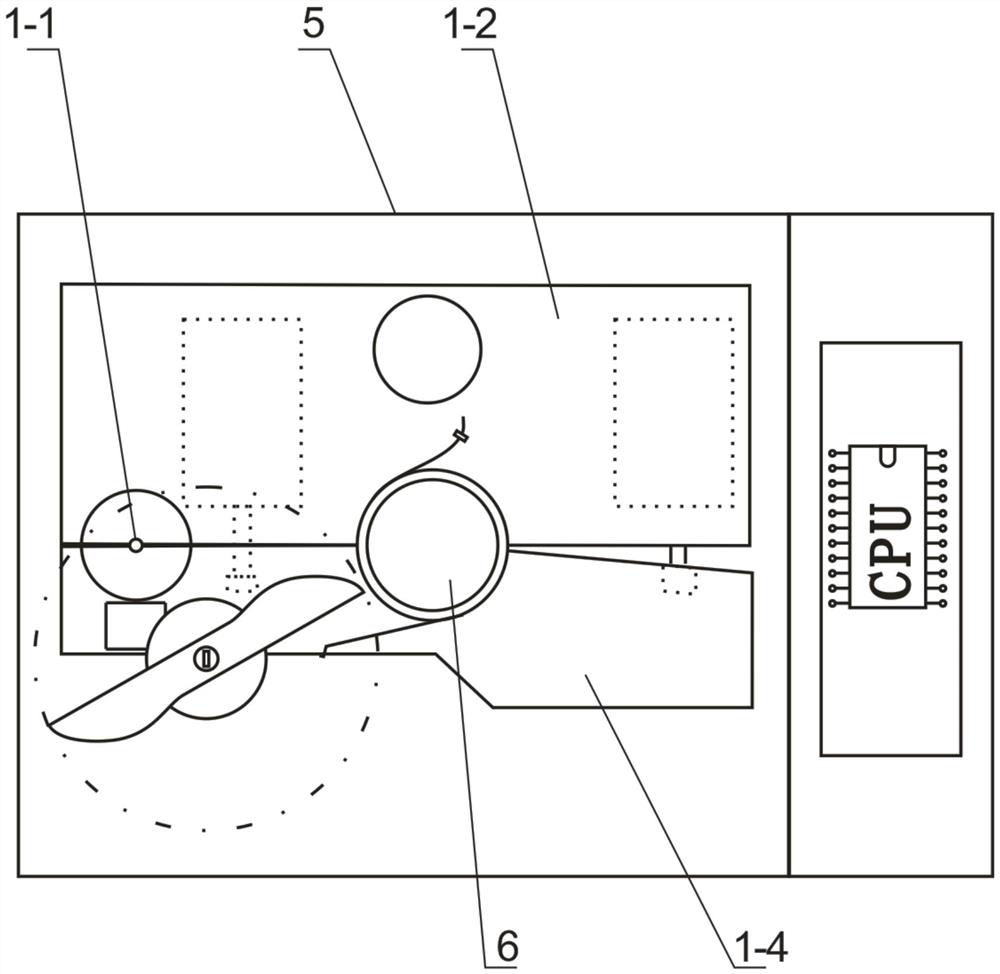

[0078] The needle pincer head 1 is used to hold the needle, and then moves downward with the needle, and is inserted into the sleeve 11, and the needle tip 12-1 is wrapped with the sleeve. Therefore, the virtual central axis must pass through the center of the needle holding hole 1-1, so that the needle tip is aligned with the cannula.

[0079] refer to figure 1 , the pincer-shaped head is arranged horizontally and laterally, and is composed of two generally rectangular parallelepiped first and second pliers 1-4. The first pincer head and the second pincer head 1-4 can be made of nylon plastic or aluminum alloy. Because the pincer head is a moving part, it is better to use stainless steel in order to prolong the service life of the equipment in consideration of wear and tear. When adopting nylon plastics and aluminum alloy to make, need to install stainless steel cover shell additionally at wear and tear position, for example install stainless steel sleeve additionally at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Cross-sectional diameter | aaaaa | aaaaa |

| Cross-sectional diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com