Cleaning equipment used before beefsteak processing and using method thereof

A technology for cleaning equipment and steaks, applied to meat processing equipment, processed meat, separation methods, etc., can solve problems such as inconvenient operation, impact, and poor working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The present invention is further described below with reference to the examples.

[0035]The following examples are intended to illustrate the invention, but cannot be used to limit the scope of the invention. The conditions in the embodiment may be further adjusted according to the specific conditions, and the method of the present invention is simply improved in the present invention in the premise of the present invention.

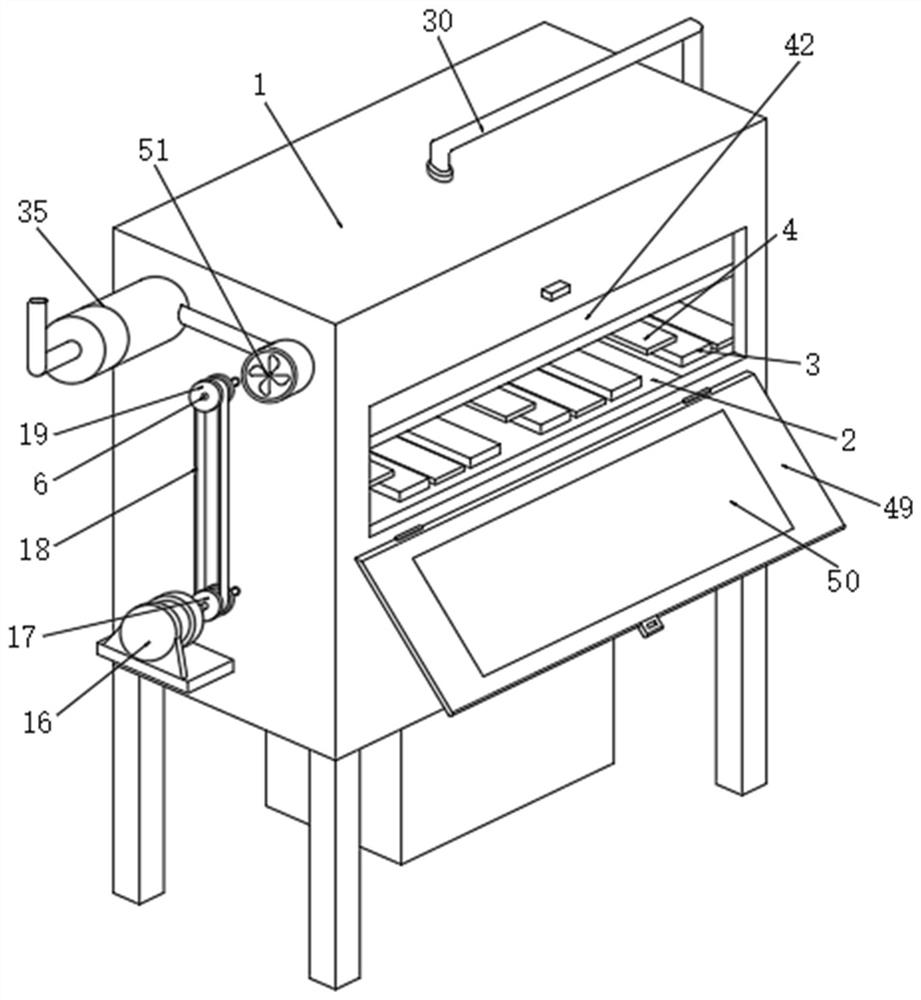

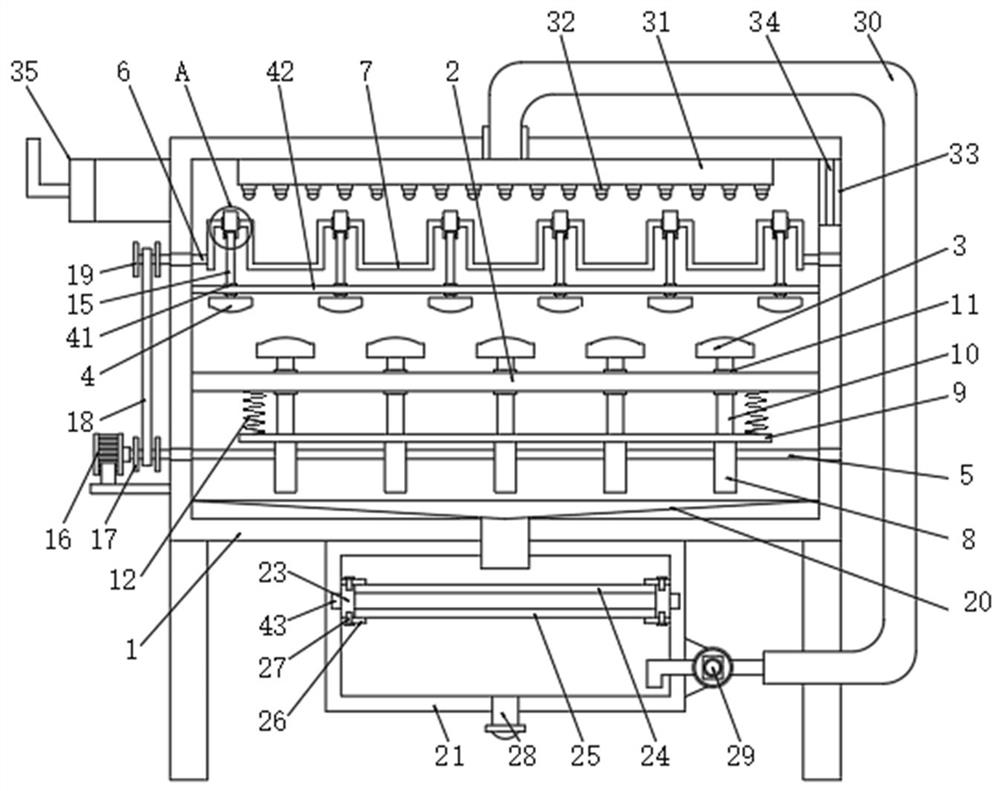

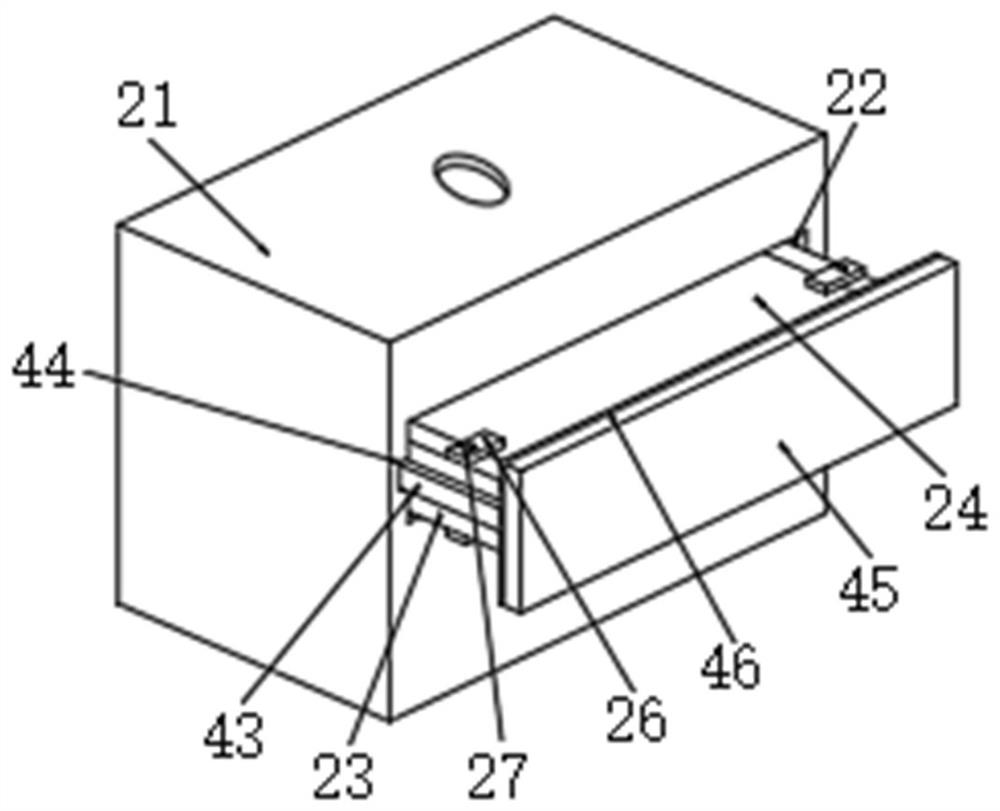

[0036]SeeFigure 1-6The present invention provides a cleaning apparatus for steak processing, including the cleaning casing 1 and the surface having a transparent window 50 and hinged to the sealing door 49 on the cleaning case 1, and the internal level of the cleaning case 1 is mounted with place plate 2, the upper mutual interleaved placement plate 2 has several hitting one 3 and hitting the hammer two 4, and the cleaning casing 1 is installed on the drive assembly for driving the hammer one 3 and hitting the hammer two 4 relative movement To achieve a hit t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com