Flexible circuit board processing and fixing device capable of preventing static electricity and collecting dust

A flexible circuit board and fixing device technology, which is applied in the processing of insulating substrates/layers, printed circuits, and printed circuit manufacturing, etc., can solve the problems of easy static electricity, easy occurrence of static electricity, and waste of manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

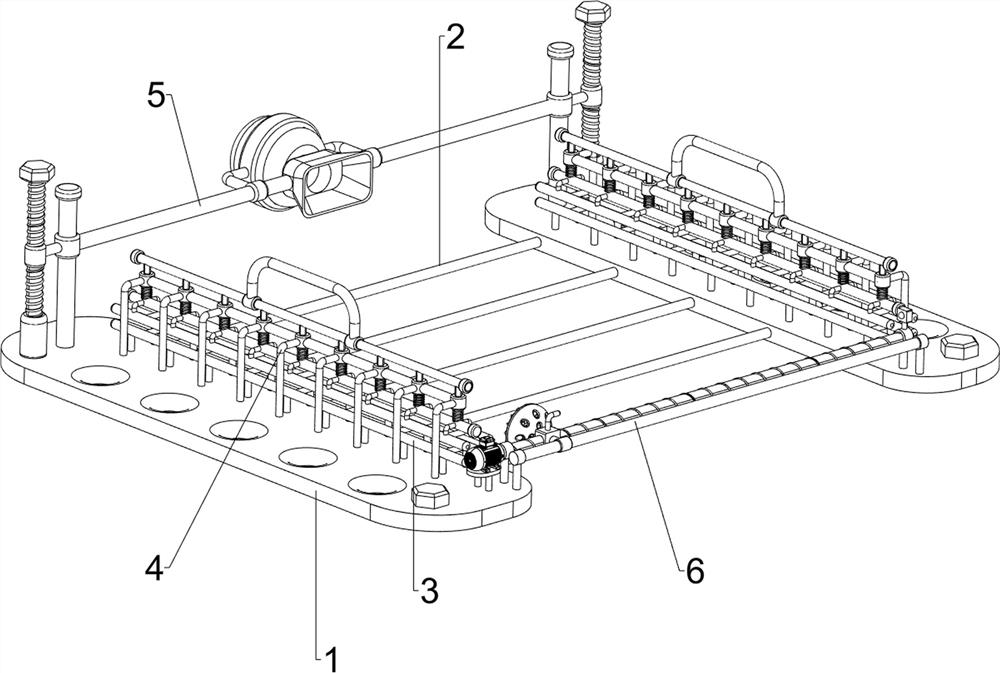

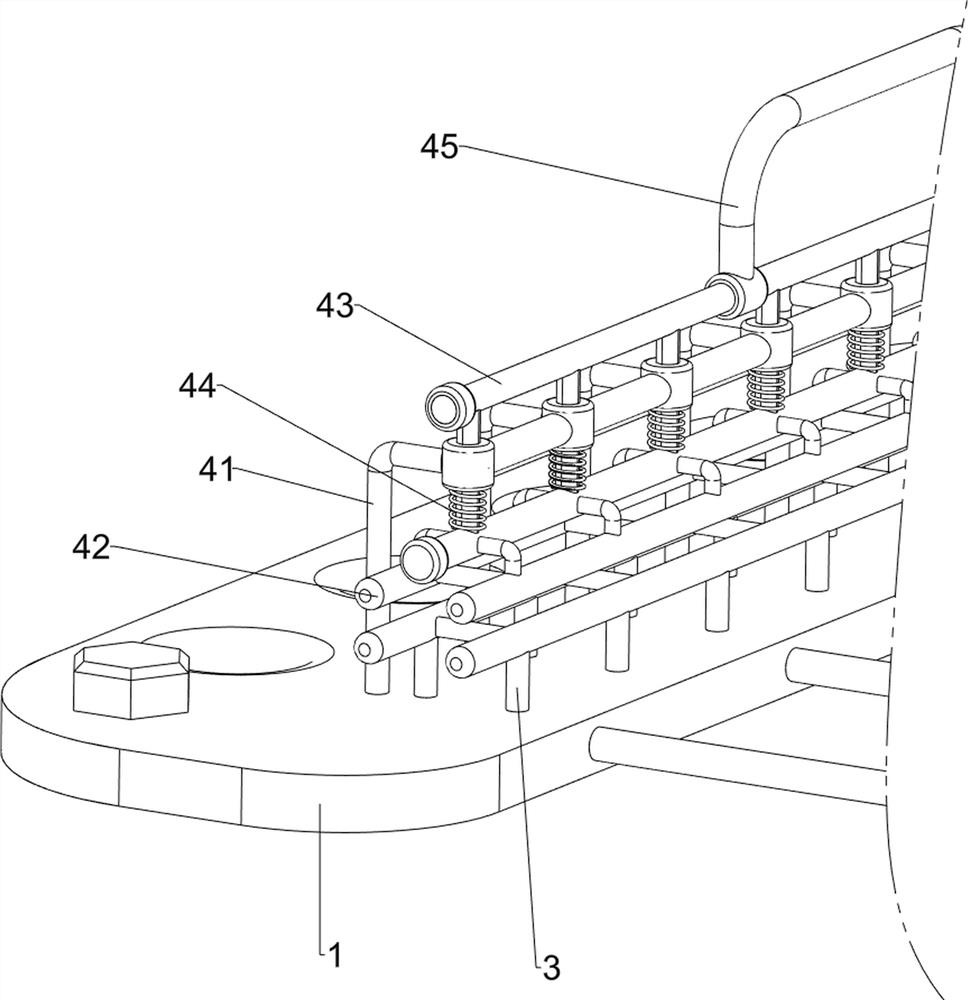

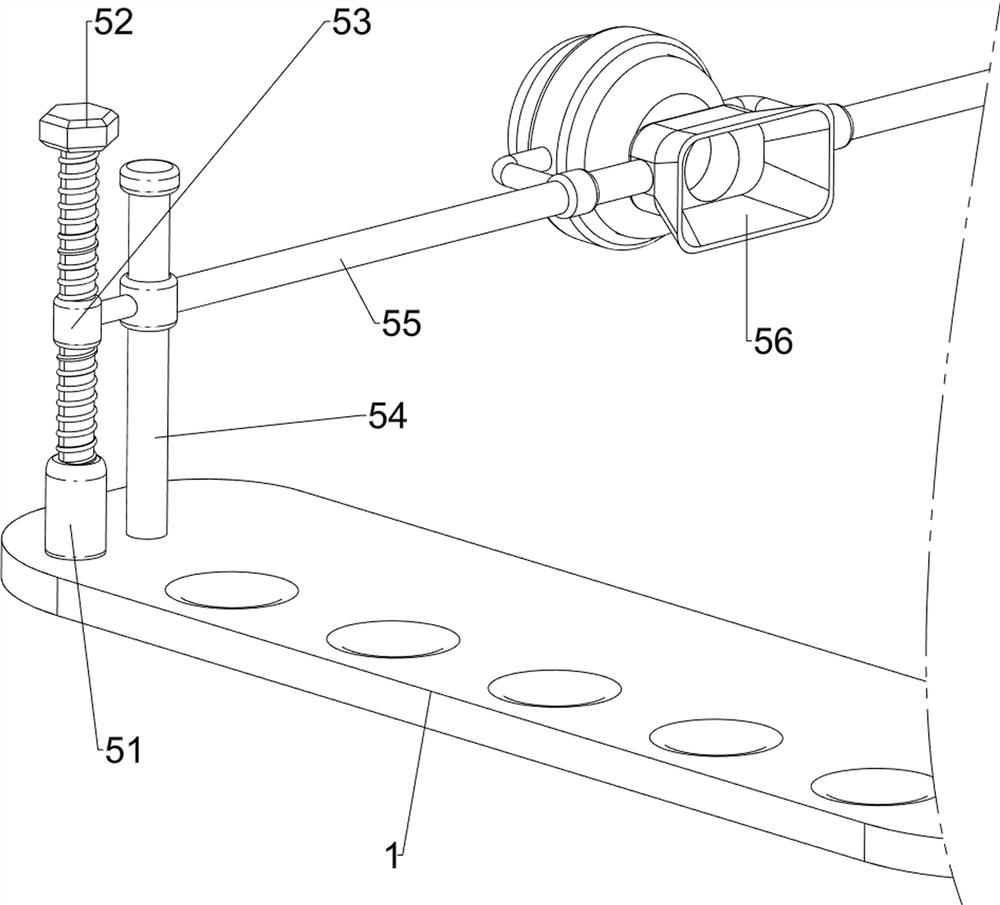

[0022] An anti-static and dust-absorbing flexible circuit board processing and fixing device, such as Figure 1-Figure 3 As shown, it includes a base 1, a connecting rod 2, a rubber support column 3, a clamping mechanism 4 and a dust collection mechanism 5, five connecting rods 2 are arranged between the base 1, and a rubber support column 3 is provided on the upper part of the base 1. A clamping mechanism 4 is provided on the outside of the rubber support column 3 , and a dust suction mechanism 5 is provided at both ends of the rear side of the base 1 .

[0023] When people use the device, place the device on the desktop, place the circuit board on the rubber support column 3, manually press down the clamping mechanism 4, clamp the circuit board by the clamping mechanism 4 on the rubber support column 3, and pass The dust suction mechanism 5 vacuums the circuit board. After the circuit board is cleaned up, the dust suction mechanism 5 is closed, the clamping mechanism 4 is lo...

Embodiment 2

[0029] On the basis of Example 1, such as Figure 4 As shown, it also includes a dust blowing mechanism 6, the base 1 upper front is provided with a dust blowing mechanism 6, and the dust blowing mechanism 6 includes a support 61, a screw rod 62, a second threaded seat 63, a switch 64, a blower 65, and a mounting seat 66 , motor 67 and slide rail 68, base 1 is provided with support 61 symmetrically front and back, rear side support 61 two ends are rotatably provided with screw rod 62, and screw rod 62 middle part threaded type is provided with second threaded seat 63, right rear top A switch 64 is provided, a blower 65 is arranged on the rear side of the second threaded seat 63, the second threaded seat 63 is connected with the blower 65, a mounting seat 66 is provided at the bottom left side of the base plate, and a motor 67 is arranged on the mounting seat 66, and the two sides of the screw rod 62 Connect the motor 67 and the inside of the bracket 61 respectively. The front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com