Self-adaptive anti-slip double-roller structure for wheel rail type rotary table

A self-adaptive, wheel-rail technology, applied in the direction of using feedback control, etc., can solve the problems of reducing the motion performance of the turntable, poor pointing accuracy, uneven force on the wheel set, etc., to simplify the structure of the turntable, reduce the design workload, Ease of use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

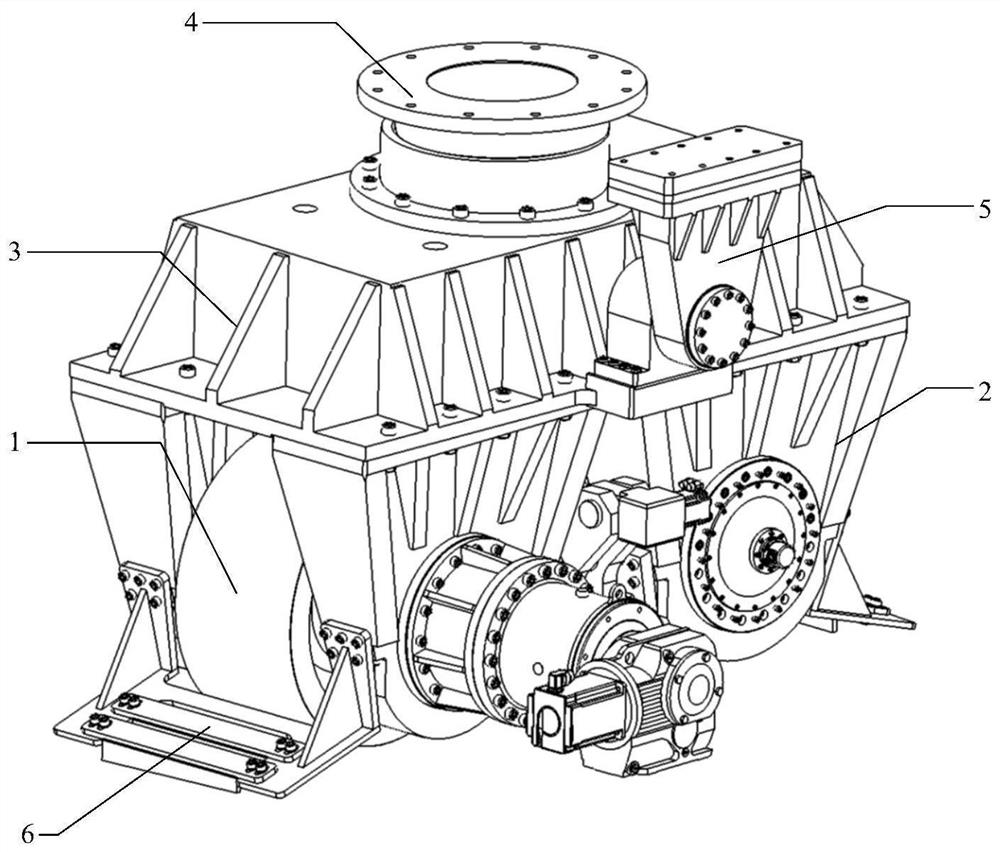

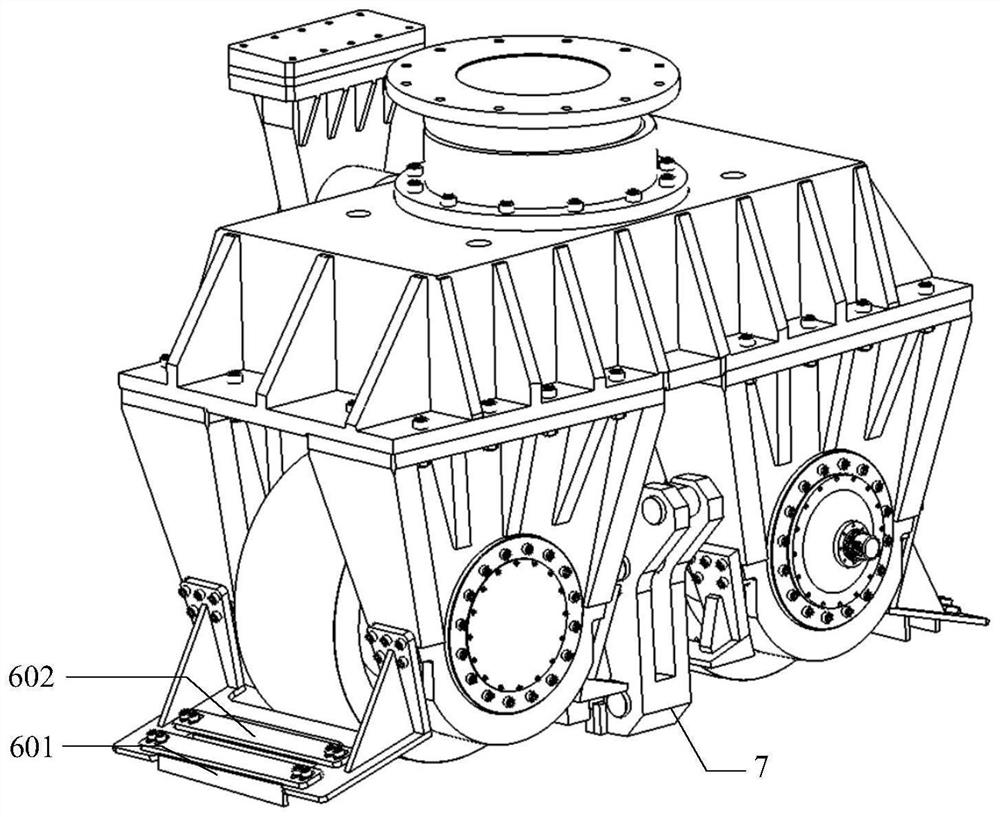

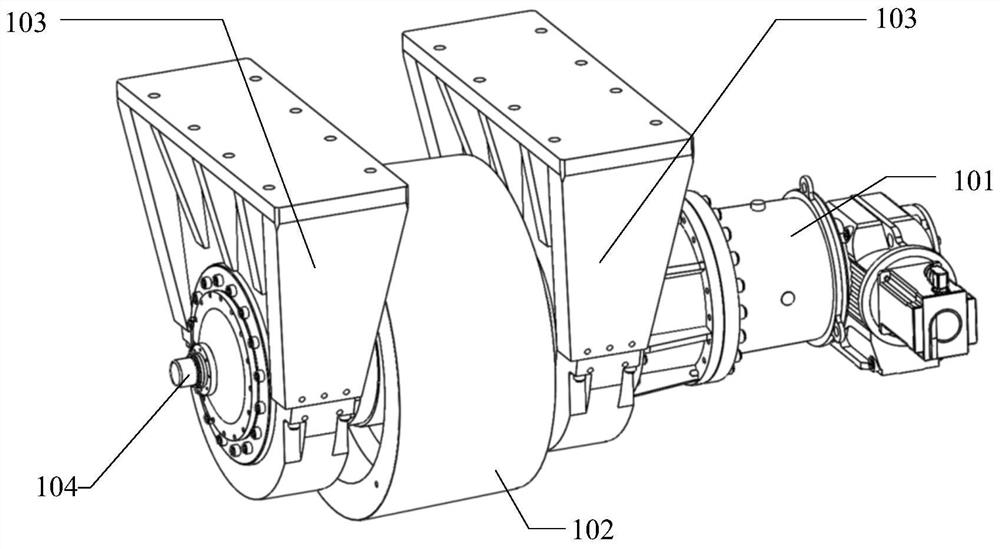

[0024] The present invention provides an adaptive anti-skid double roller structure for a wheel-rail turntable, which includes a driving wheel assembly 1 and a driven wheel assembly 2 connected through a wheel set connector 3 . The driving wheel assembly 1 includes a driving shaft and a driving roller 102 arranged on the driving shaft. Both sides of the driving roller 102 are provided with first self-aligning bearings, and the first self-aligning bearings are connected to the wheel set through the first bearing seat 103. 3 are connected, one end of the driving shaft is connected to the servo drive assembly 101, the other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com