A Control Method for Reducing the Slipping Effect of Tension Rollers

A technology of tension roller set and control method, applied in the direction of tension/pressure control etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

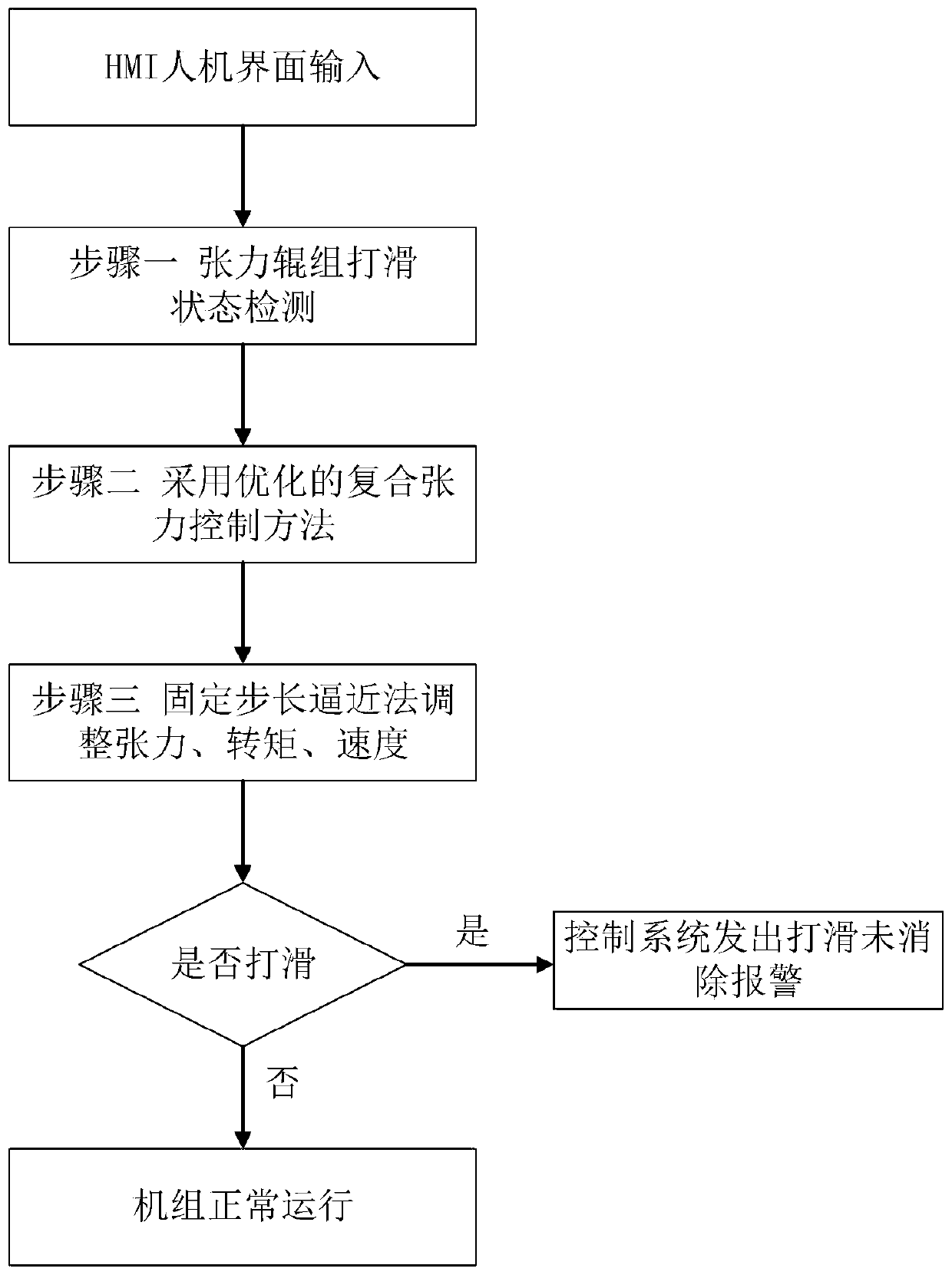

[0054] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

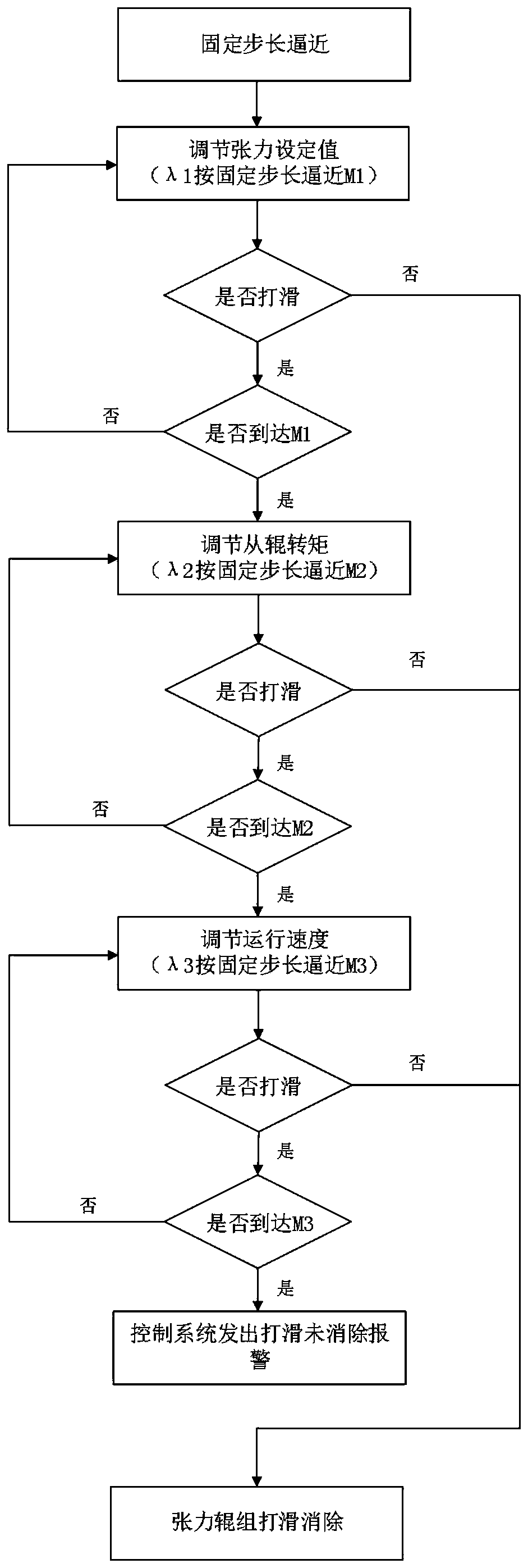

[0055] like image 3 shown below, the steps to reduce the effect of tension roller set slip are as follows:

[0056] Step 1. Monitoring of the slip state of the tension roller group

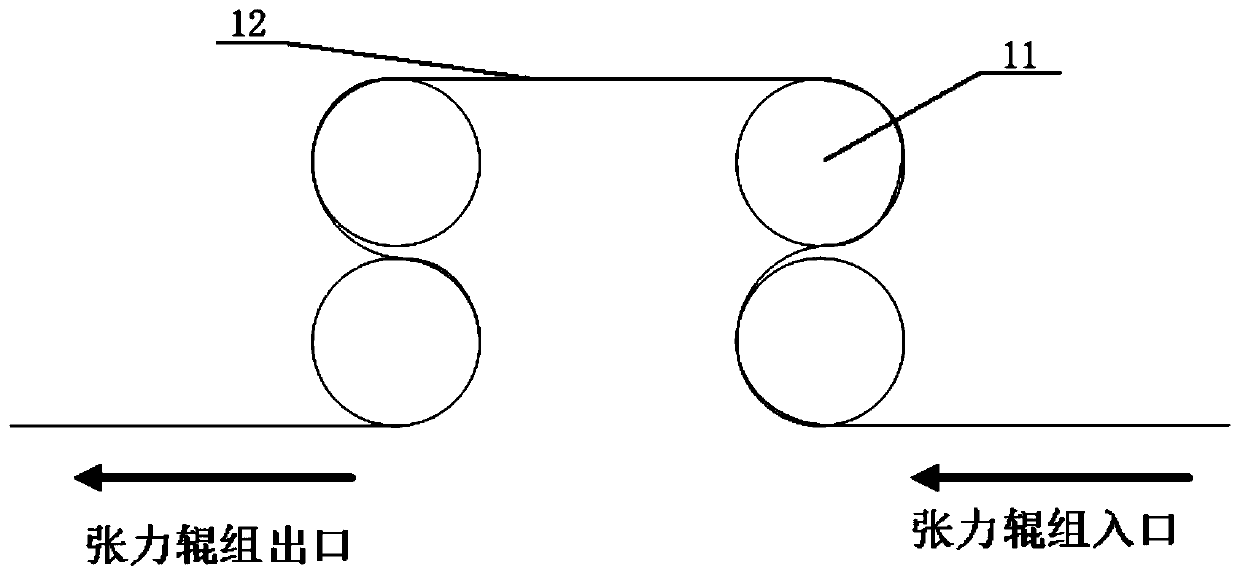

[0057] The structure of the tension roll group of the cold-rolled strip production line is as follows figure 1 As shown in the figure, whether it is in the power generation state or the electric state, once the tension difference of the strip steel 12 at both ends of the tension roller 11 is greater than the friction force at the wrapping angle of the tension roller, the strip steel 12 tends to frictional sliding at the wrapping angle, that is, slipping .

[0058] There are some common laws when the tension roll group of the cold-rolled strip production line slips:

[0059] 1. Slippage will change the tension value of each section, and it is impossible to achieve con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com