Vehicle torque distribution device and method

A torque distribution method and torque distribution technology, applied in electrical devices, control devices, vehicle components, etc., can solve problems such as reducing wheel slip, accelerating tire wear, and excessive wheel slip, and improving driving stability. , prolong the service life, increase the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

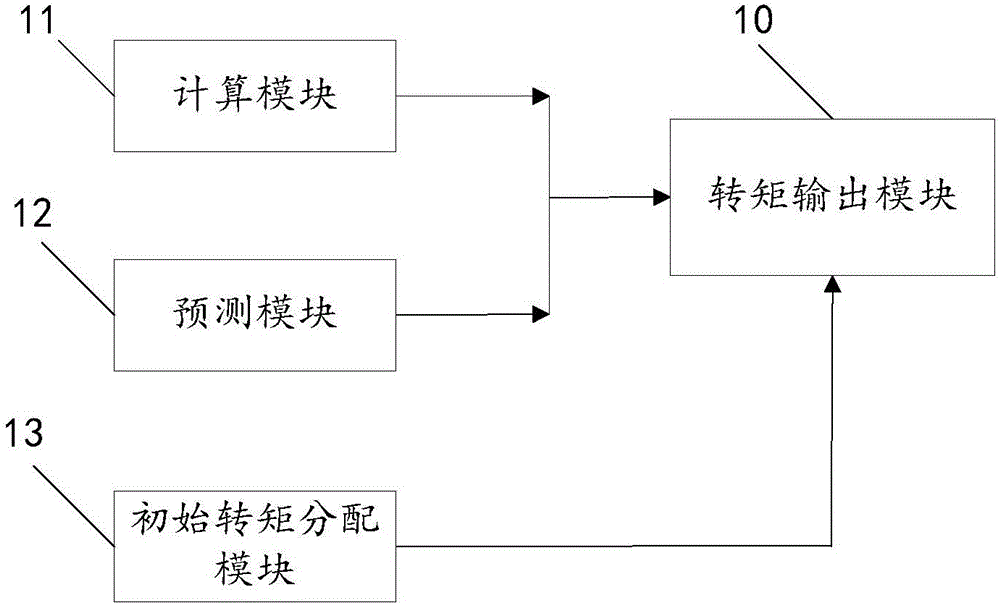

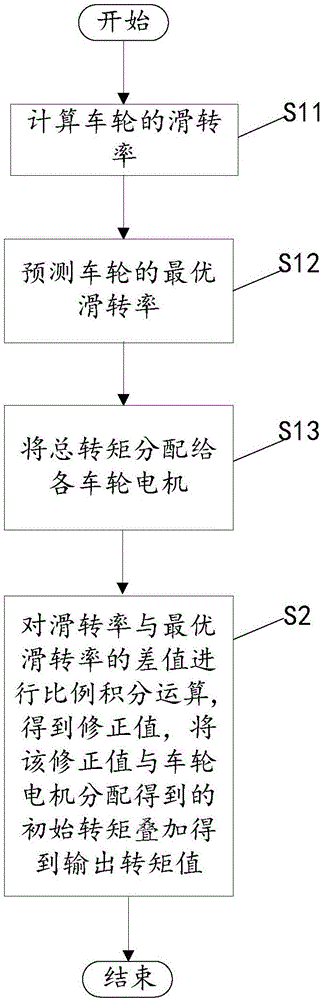

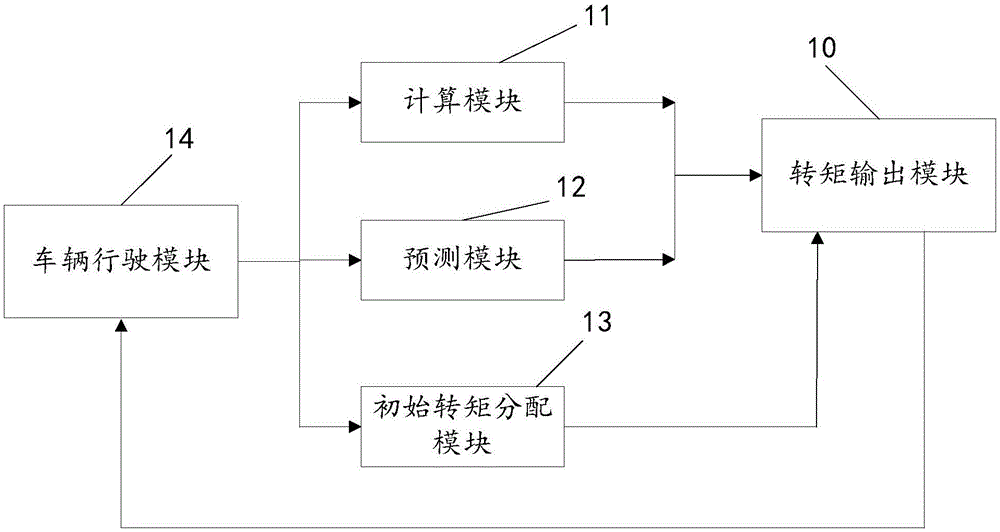

[0033] Such as figure 1 As shown, the vehicle torque distribution device of the present invention includes a calculation module 11 , a prediction module 12 , an initial torque distribution module 13 and a torque output module 10 . The calculation module 11 is connected with the torque output module 10 for calculating the slip ratio of the wheel and sending the calculated slip ratio to the torque output module 10 . The prediction module 12 is connected with the torque output module 10 and is used to predict the optimal slip ratio of the wheels, and send the predicted optimal slip ratio to the torque output module 10 . The initial torque distribution module 13 is connected with the torque output module 10 , and is used for distributing the total torque to each wheel motor, and sending the initial torque distributed by each wheel motor to the torque output module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com