Shear wall formwork opposite-pull connecting pieces and formwork reinforcing structure thereof

A formwork reinforcement and shear wall technology, which is applied to formwork/formwork/workframe connectors, building structures, and on-site preparation of building components, can solve the problem of affecting the construction weight of shear walls and the cumbersome reinforcement process , mold expansion and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

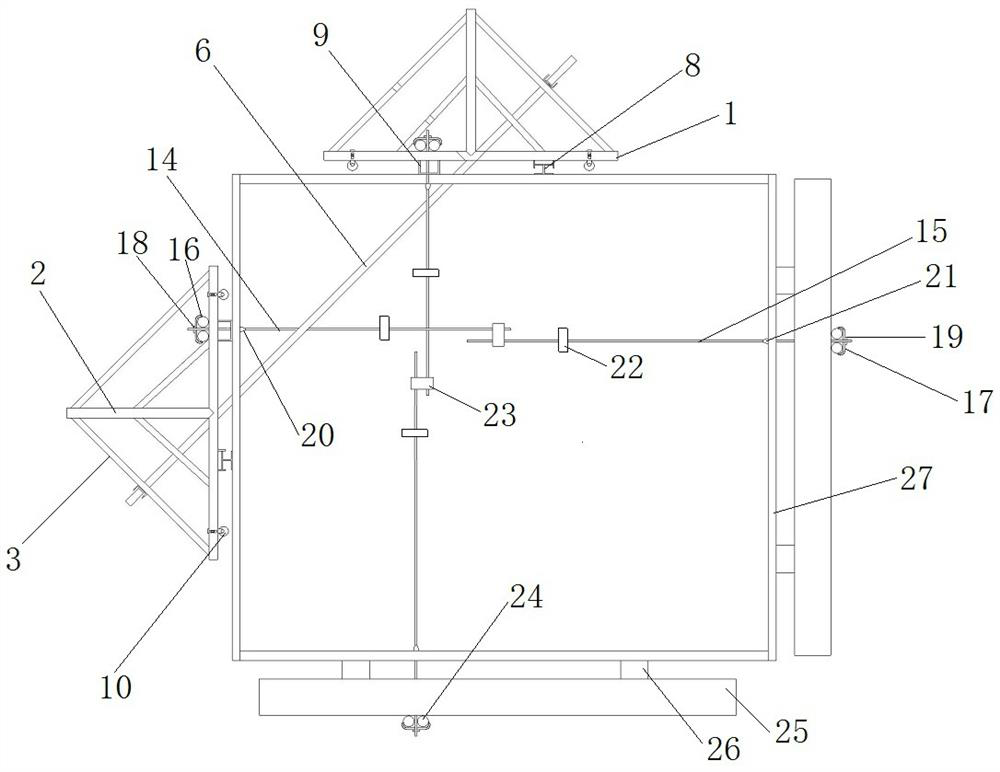

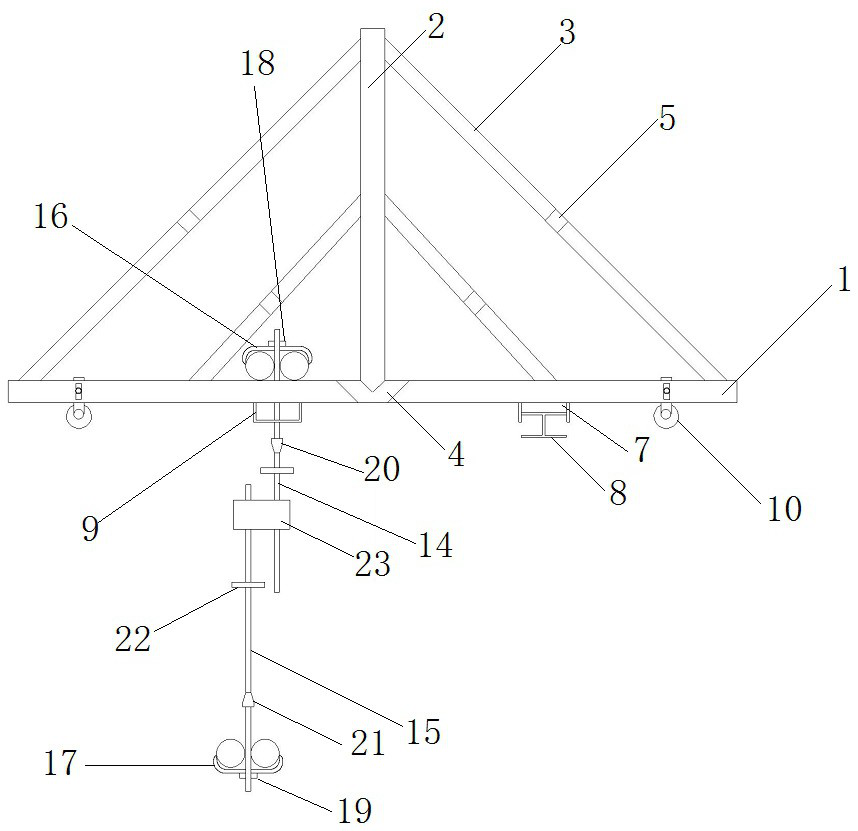

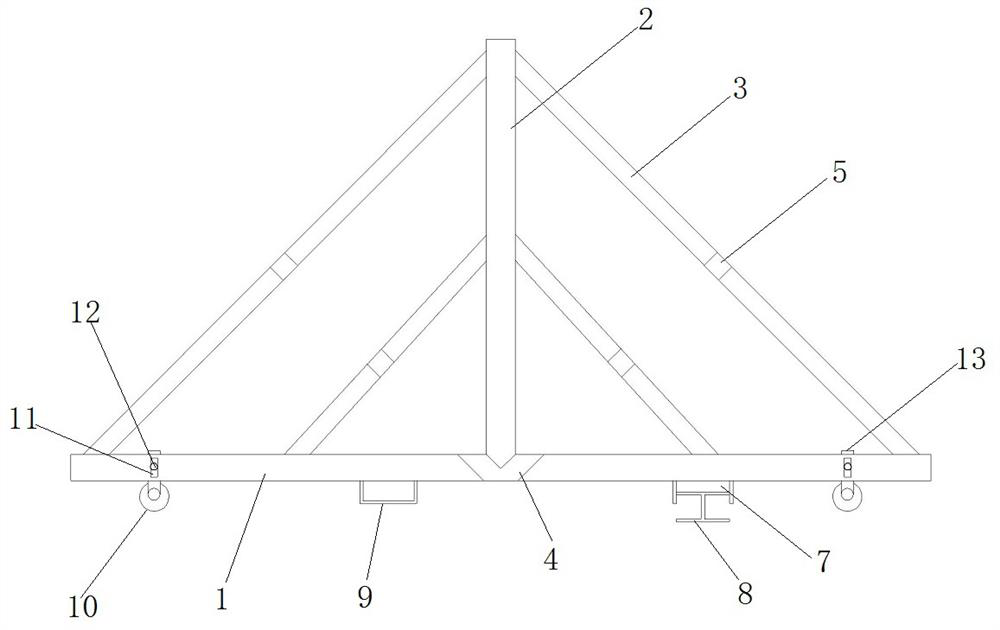

[0060] The reinforcement structure of the shear wall formwork includes a shear wall formwork 27 , a pair of shear wall formwork connectors, a square pipe 25 and a skid 26 . Wherein, the structure of the shear wall formwork pair-tension connector is exactly the same as that of the shear wall formwork pair-tension connector in the above-mentioned embodiment, and will not be repeated here, and the above-mentioned structure is directly used. refer to figure 1 , the square tube 25 is arranged on the outside of the shear wall formwork parallel to the shear wall formwork in contact with the cable-stayed reinforcement assembly, and the skid 26 is arranged between the shear wall formwork and the square tube 25. At this time, the second pair of Pull rod 15 passes through square pipe 25 and the shear wall template 27 corresponding to square pipe 25 simultaneously, and the second butterfly clip 17 is positioned at the side of square pipe 25 facing away from skid 26, by tightening second f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com