Energy consumption connecting joint of shear wall

A technology for connecting nodes and shear walls, applied in the direction of walls, building components, building structures, etc., can solve problems such as damage, and achieve the effect of increasing support points, not easy to fail, and increasing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

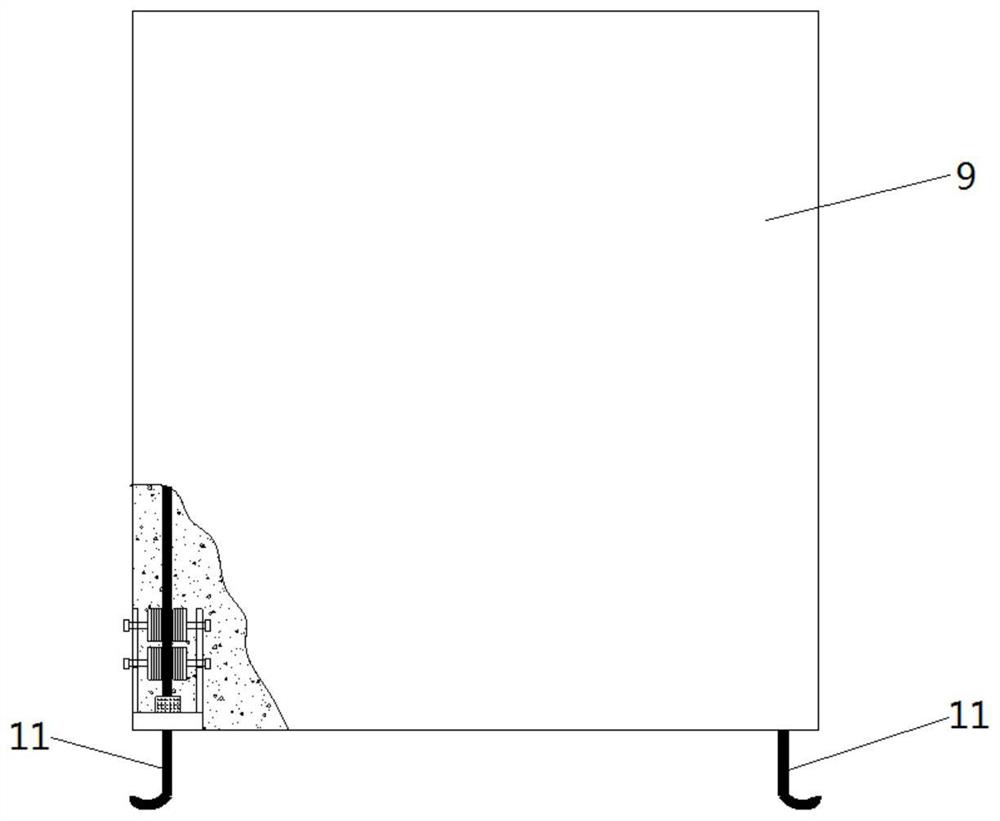

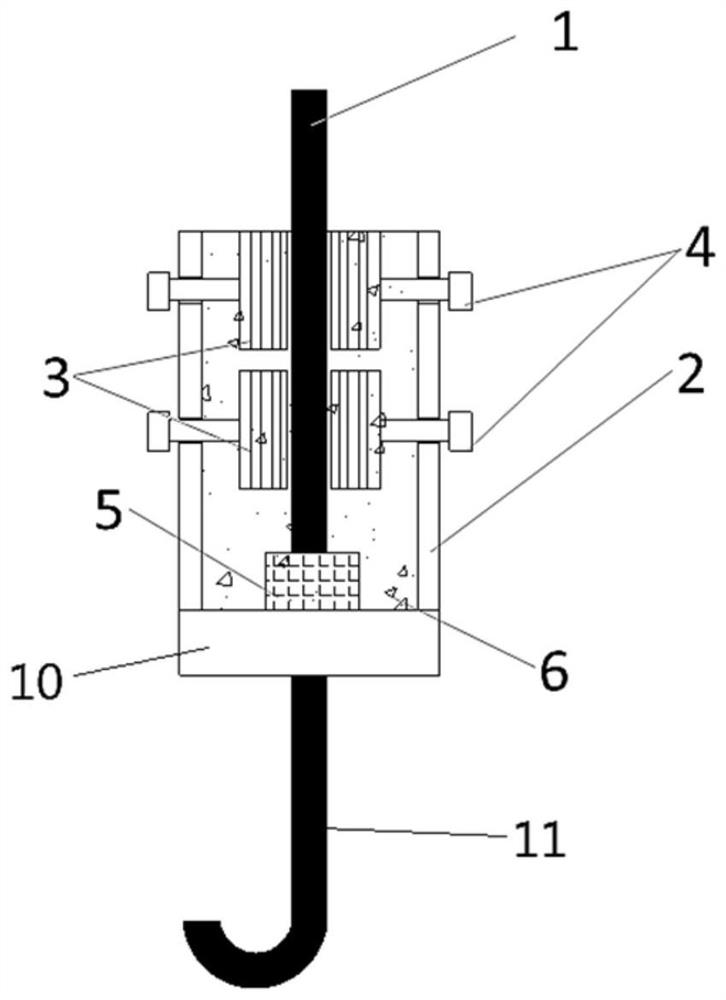

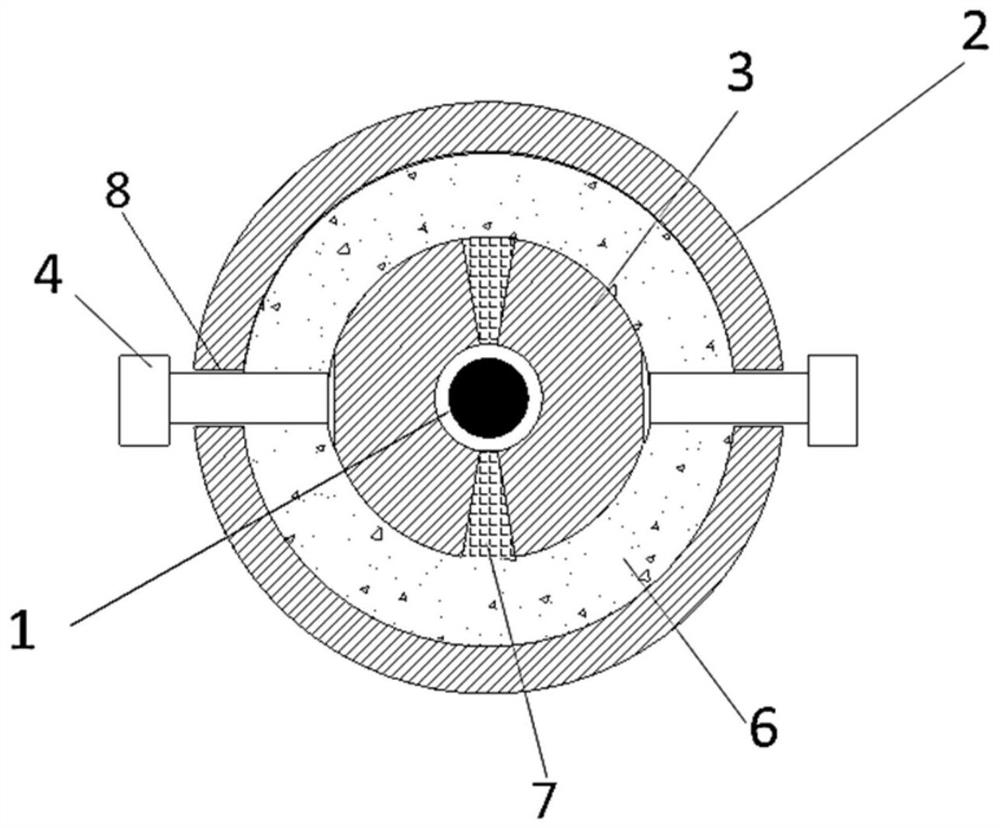

[0034] An energy-dissipating connecting node of a shear wall, used to connect the shear wall 9 and the connected parts, such as figure 1 , figure 2 and image 3 , comprising a first connection module and a second connection module pre-embedded in the corner of the shear wall 9 and the connected parts respectively, the first connection module and the second connection module are connected, the first connection module includes a steel bar 1 and a casing 2, The steel bar 1 is inserted into the casing 2, and two frictional energy dissipation units are arranged between the steel bar 1 and the casing 2, and the two frictional energy dissipation units are arranged at intervals along the axial direction of the casing 2, and each frictional energy dissipation unit includes two friction plates 3 and the corresponding two pre-tightening bolts 4, the two friction plates 3 surround and cling to the side wall of the steel bar 1, the sleeve 2 has a threaded hole 8, the end of the pre-tight...

Embodiment 2

[0048] Such as Figure 5 , the structure of the second connection module is the same as that of the first connection module in this embodiment, and they are arranged symmetrically. 5 Integrated design, simple structure, further improves the ductility of energy-dissipating connection nodes. Others are the same as in Example 1.

[0049] Embodiment 1 and Embodiment 2 propose an energy-dissipative connection node of a shear wall, which applies friction to the steel bar 1 through the casing 2, the pre-tightening bolt 4 and the friction plate 3. When the steel bar 1 is axially loaded along the casing 2 Relative sliding occurs when the force is greater than the frictional force, so as to prevent the steel bar 1 from yielding due to excessive force. It has good ductility, strong energy dissipation capacity, and is not easy to be damaged. At the same time, it is easy to disassemble and assemble, and is convenient for repair and replacement of damaged corners.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com