High-speed rail bridge adjacent isolation pile foundation and overload construction model test system

A technology of model testing and isolated piles, which is applied in the fields of geotechnical engineering and bridge engineering, can solve the problems that have not yet been considered in the surcharge construction, isolation pile construction, high-speed rail vibration coupling model test system, etc., to achieve strong adaptability to working conditions, The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

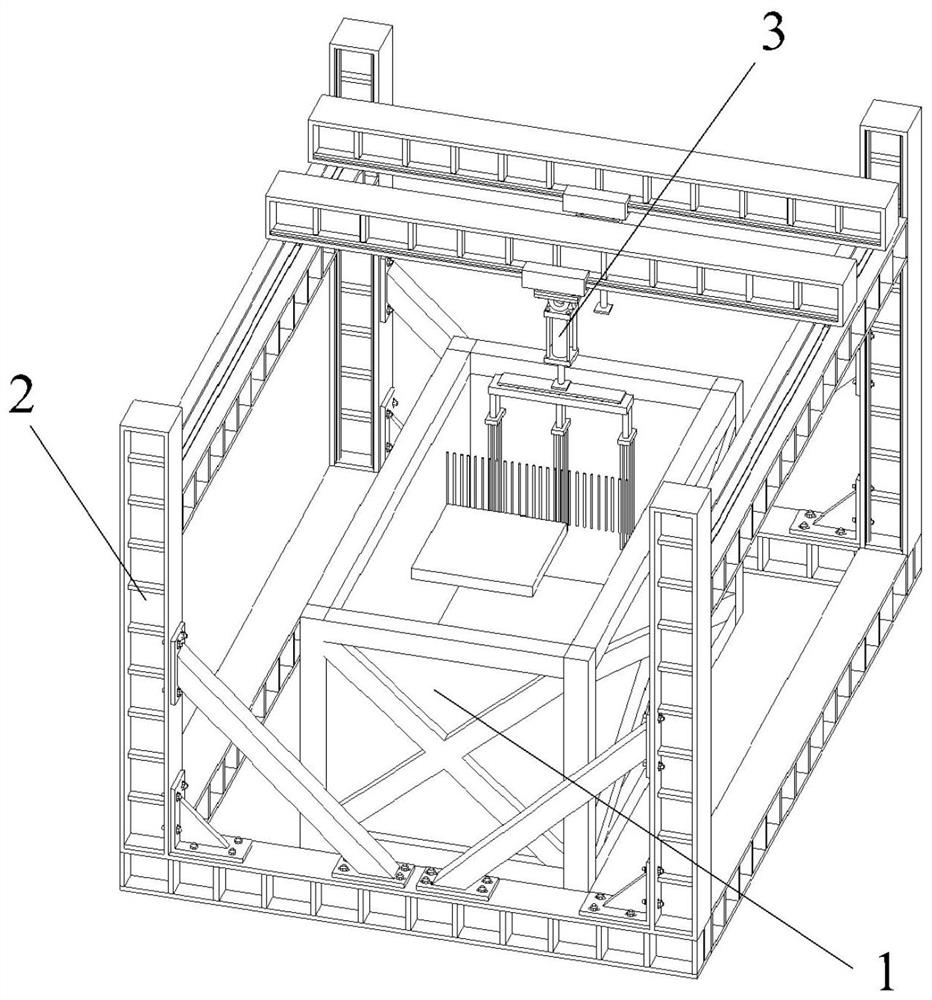

[0058] Example 1: Pile row penetration construction test

[0059] Control the longitudinal beam 203 of the reaction force frame 2 to move along the Z-axis guide rail 210, the No. I beam 2041 to move along the Y-axis guide rail 209, and the transmission block 205 to move along the X-axis guide rail 208, and the servo drive connected to the No. I beam 2041 The actuator 301 moves to the pile position of the isolated pile foundation 103 to be constructed; the servo actuator 301 is raised to a certain height, and the first isolated pile foundation 103 to be constructed is erected upright to ensure that the pipe pile is vertical to prevent eccentric compression; and then through the loading system 3 Pressurize, the servo actuator 301 descends slowly and at a uniform speed, and pushes the first isolated pile foundation 103 to be constructed to be pressed into the soil; if the stroke of the servo actuator 301 is insufficient, it can be pressed in multiple times to complete the first is...

Embodiment 2

[0060] Embodiment 2: Heap load construction test

[0061] In the model test box 101, the surface of the soil sample material in the target test area is divided and marked to be piled up, and the soil material 102 to be piled up is stacked to a predetermined position to complete the application of the first-level pile load; then continue to pile up the soil sample material load until it reaches the predetermined height, and complete the secondary and tertiary stacking.

Embodiment 3

[0062] Example 3: High-speed rail operation vibration test

[0063] Before filling the soil sample material in the model test box 101, mark the embedding position of the high-speed rail bridge model 104 on the inner wall of the side plate 1015. When the soil is filled to the vicinity of the marked area, put the high-speed rail bridge model 104 into it, and fill the soil while ensuring the vertical state of the model To the predetermined elevation, cover the high-speed rail bridge cap 1042. When filling to the bridge pile foundation 1041, pay attention to compact the soil sample material near the bridge pile foundation 1041; place the loading distribution beam 304 on the track fastener of the bridge deck 1044 to load The contact 1045 is fixed, and the longitudinal beam 203 of the control reaction force frame 2 moves along the Z-axis guide rail 210, the No. II beam 2042 moves along the Y-axis guide rail 209, and the transmission block 205 moves along the X-axis guide rail 208. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com